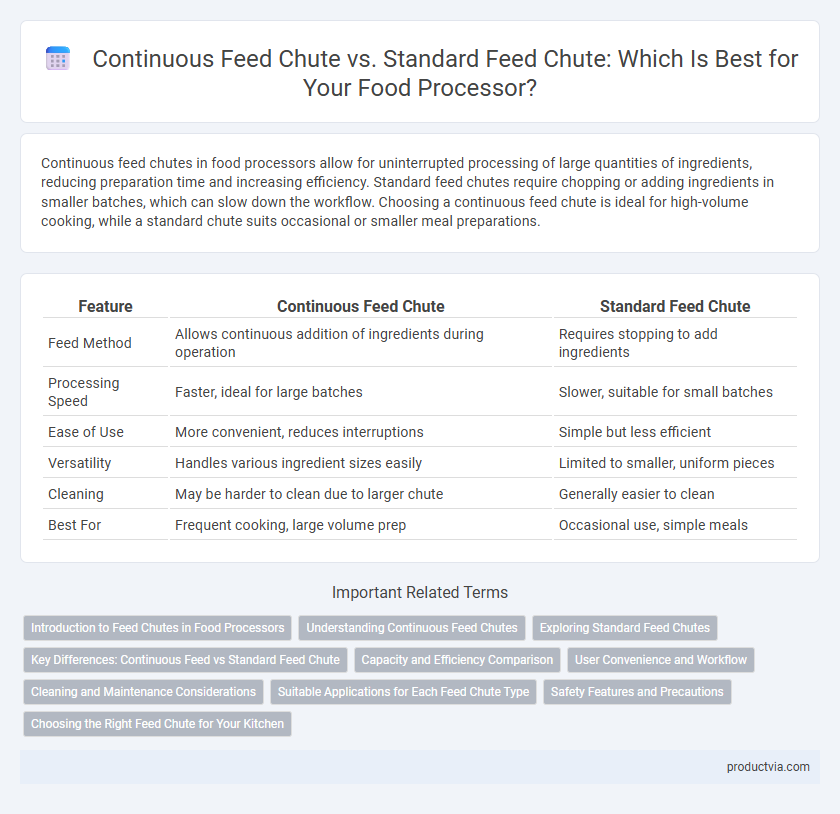

Continuous feed chutes in food processors allow for uninterrupted processing of large quantities of ingredients, reducing preparation time and increasing efficiency. Standard feed chutes require chopping or adding ingredients in smaller batches, which can slow down the workflow. Choosing a continuous feed chute is ideal for high-volume cooking, while a standard chute suits occasional or smaller meal preparations.

Table of Comparison

| Feature | Continuous Feed Chute | Standard Feed Chute |

|---|---|---|

| Feed Method | Allows continuous addition of ingredients during operation | Requires stopping to add ingredients |

| Processing Speed | Faster, ideal for large batches | Slower, suitable for small batches |

| Ease of Use | More convenient, reduces interruptions | Simple but less efficient |

| Versatility | Handles various ingredient sizes easily | Limited to smaller, uniform pieces |

| Cleaning | May be harder to clean due to larger chute | Generally easier to clean |

| Best For | Frequent cooking, large volume prep | Occasional use, simple meals |

Introduction to Feed Chutes in Food Processors

Continuous feed chutes in food processors enable seamless processing by allowing ingredients to be added without stopping the machine, enhancing efficiency for large or repetitive tasks. Standard feed chutes require the processor to be paused for ingredient addition, making them suitable for smaller or less frequent processing jobs. Choosing the appropriate feed chute depends on the volume and speed requirements of food preparation tasks.

Understanding Continuous Feed Chutes

Continuous feed chutes allow users to add ingredients while the food processor is running, enhancing efficiency and reducing preparation time. This feature is ideal for processing large quantities or incorporating multiple ingredients without stopping the motor. In contrast, standard feed chutes require the processor to be paused for ingredient addition, limiting workflow speed and convenience.

Exploring Standard Feed Chutes

Standard feed chutes in food processors typically feature a narrow opening designed for smaller batches and precise ingredient control. These chutes require pre-cutting larger items but provide stability and reduce the risk of jams during processing. Choosing a standard feed chute is ideal for users who prioritize accuracy and bevy of fine textures in chopping, slicing, and grating tasks.

Key Differences: Continuous Feed vs Standard Feed Chute

Continuous feed chutes in food processors allow users to add ingredients without stopping the machine, ideal for processing large quantities efficiently, while standard feed chutes require pausing to add components. The continuous feed chute typically features a larger opening, accommodating whole vegetables and fruits, which speeds up prep time compared to the smaller, more controlled stroke size of standard chutes. Continuous feed models excel in multitasking and volume processing, whereas standard feed chutes offer precision and better control for delicate tasks.

Capacity and Efficiency Comparison

Continuous feed chutes in food processors offer significantly higher capacity, allowing users to process larger volumes of ingredients without frequent pauses, enhancing overall efficiency. Standard feed chutes typically have a smaller opening, requiring ingredients to be cut into smaller pieces and added more frequently, which can slow down food preparation. The larger diameter of continuous feed chutes streamlines workflows in kitchens, especially when handling bulky items like whole vegetables or fruits.

User Convenience and Workflow

A continuous feed chute enhances user convenience by allowing ingredients to be added without stopping the food processor, streamlining workflow and reducing preparation time. In contrast, a standard feed chute requires pausing to add ingredients, potentially interrupting the process and slowing down productivity. Continuous feed chutes are ideal for handling large quantities efficiently, improving overall kitchen workflow.

Cleaning and Maintenance Considerations

Continuous feed chutes simplify cleaning by minimizing food buildup, allowing ingredients to flow steadily through the processor without frequent interruptions. Standard feed chutes often require more disassembly and manual cleaning due to smaller openings and tighter spaces where food particles can accumulate. Choosing a continuous feed chute can reduce maintenance time and enhance overall hygiene by preventing residue clogging during processing.

Suitable Applications for Each Feed Chute Type

Continuous feed chutes excel in processing larger quantities of ingredients quickly, making them ideal for repetitive tasks like slicing or shredding vegetables. Standard feed chutes are better suited for precise, smaller batch preparations where control over ingredient size and texture is crucial, such as chopping nuts or grating cheese. Choosing the appropriate feed chute depends on the volume and type of food preparation required in your kitchen.

Safety Features and Precautions

Continuous feed chutes in food processors enhance safety by reducing the need to stop the machine when adding ingredients, minimizing exposure to sharp blades during operation. Standard feed chutes often require the processor to be off before adding food, which can prevent accidental activation but may lead to frequent handling near blade areas. Both designs incorporate locking mechanisms and anti-slip bases to ensure user protection, but continuous feed chutes require attentive use of pusher tools to avoid hand injuries.

Choosing the Right Feed Chute for Your Kitchen

Choosing the right feed chute for your food processor depends on your kitchen workflow and ingredient types. Continuous feed chutes allow larger quantities and taller items to be processed without constant stops, ideal for high-volume cooking or batch food preparation. Standard feed chutes suit precise, small-batch tasks where controlled input helps achieve consistent slicing or chopping results.

Continuous feed chute vs Standard feed chute for food processor Infographic

productvia.com

productvia.com