Direct drive motors in food processors offer higher efficiency and durability by connecting the motor directly to the blade, reducing energy loss and maintenance needs. Belt drive motors, while typically quieter and less expensive, may experience slippage and wear over time, affecting performance and reliability. Choosing between the two depends on whether you prioritize power and longevity or cost and noise reduction in your food processor.

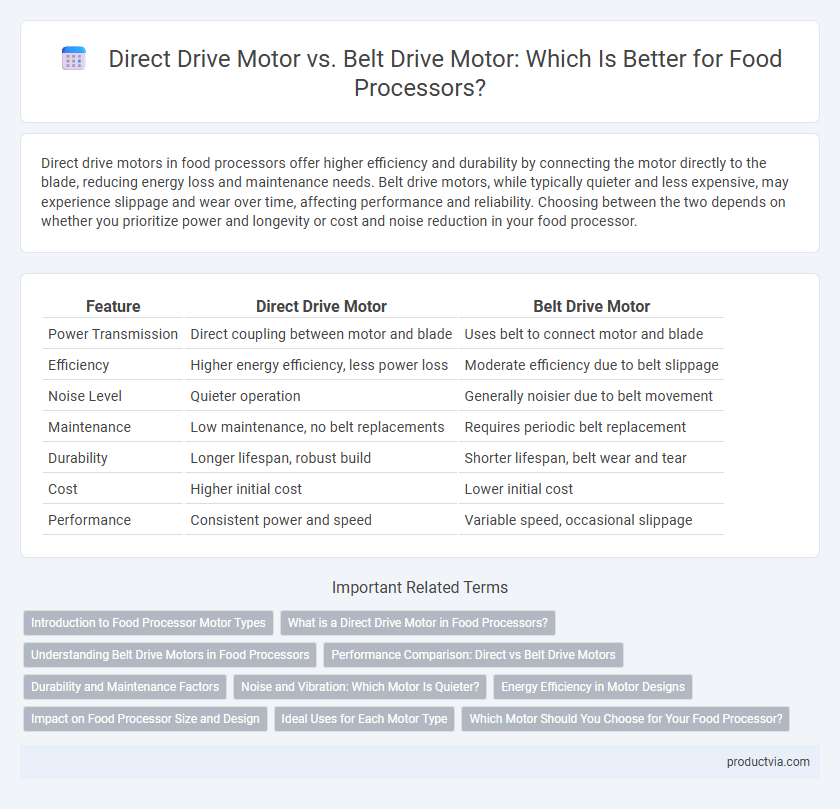

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Power Transmission | Direct coupling between motor and blade | Uses belt to connect motor and blade |

| Efficiency | Higher energy efficiency, less power loss | Moderate efficiency due to belt slippage |

| Noise Level | Quieter operation | Generally noisier due to belt movement |

| Maintenance | Low maintenance, no belt replacements | Requires periodic belt replacement |

| Durability | Longer lifespan, robust build | Shorter lifespan, belt wear and tear |

| Cost | Higher initial cost | Lower initial cost |

| Performance | Consistent power and speed | Variable speed, occasional slippage |

Introduction to Food Processor Motor Types

Direct drive motors in food processors are mounted directly to the blade assembly, providing efficient power transfer and quieter operation. Belt drive motors use a rubber or silicone belt to connect the motor to the blade, allowing for smoother speed variation and reducing motor stress during heavy-duty tasks. Choosing between direct drive and belt drive impacts the processor's durability, noise level, and performance efficiency in food preparation.

What is a Direct Drive Motor in Food Processors?

A direct drive motor in food processors connects the motor shaft directly to the blade assembly, offering efficient power transfer and reduced mechanical loss. This design enhances durability and minimizes maintenance compared to belt drive motors, which rely on belts that can wear out or slip. Direct drive motors typically provide stronger torque, resulting in smoother and more consistent processing performance.

Understanding Belt Drive Motors in Food Processors

Belt drive motors in food processors use a belt to transfer power from the motor to the blade assembly, allowing for smoother operation and reduced motor noise. These motors tend to be more affordable and easier to maintain or replace compared to direct drive motors, but they may sacrifice some power efficiency and precision. Understanding the mechanics of belt drive systems helps in choosing a food processor that balances performance with durability for various kitchen tasks.

Performance Comparison: Direct vs Belt Drive Motors

Direct drive motors in food processors offer higher efficiency and consistent power transfer by connecting the motor shaft directly to the blade assembly, resulting in faster processing speeds and reduced maintenance. Belt drive motors provide quieter operation and smoother torque but may experience power loss and require periodic belt replacement, which can affect long-term performance. Overall, direct drive systems excel in heavy-duty tasks, while belt drives are better suited for lighter, quieter kitchen applications.

Durability and Maintenance Factors

Direct drive motors in food processors offer superior durability due to the absence of belts that can wear out or slip, resulting in longer-lasting performance and fewer maintenance requirements. Belt drive motors require regular inspection and replacement of belts, which can degrade over time, causing reduced efficiency and potential breakdowns. The direct connection in direct drive systems reduces mechanical parts, minimizing wear and the need for frequent servicing compared to belt drive alternatives.

Noise and Vibration: Which Motor Is Quieter?

Direct drive motors in food processors typically produce less noise and vibration due to the direct connection between the motor and the blade assembly, reducing mechanical friction and parts that generate sound. Belt drive motors often generate more noise because the belts can slip or wear over time, causing additional vibrations and operational sounds. Choosing a direct drive motor results in a quieter food processor experience with smoother performance.

Energy Efficiency in Motor Designs

Direct drive motors in food processors offer superior energy efficiency by eliminating energy loss associated with belt friction and slippage, resulting in more consistent power delivery and lower electricity consumption. Belt drive motors experience energy loss due to belt tension and wear, reducing overall efficiency and requiring more frequent maintenance. The streamlined design of direct drive motors enhances durability and performance, making them the preferred choice for energy-conscious consumers seeking optimal food processor operation.

Impact on Food Processor Size and Design

Direct drive motors in food processors allow for a more compact and streamlined design by eliminating the need for additional components like belts and pulleys, which reduces overall appliance size. Belt drive motors typically increase the footprint and thickness of the food processor due to the space required for the belt mechanism, leading to a bulkier design. The motor placement in direct drive systems enhances stability and efficiency, making them ideal for sleek, countertop-friendly models.

Ideal Uses for Each Motor Type

Direct drive motors in food processors offer efficient power transfer, making them ideal for heavy-duty tasks such as kneading dough or chopping tough vegetables. Belt drive motors provide quieter operation and are better suited for lighter, precision tasks like slicing or grating delicate ingredients. Choosing the right motor depends on the primary food processing needs and desired noise levels in the kitchen.

Which Motor Should You Choose for Your Food Processor?

Direct drive motors in food processors offer greater efficiency and durability due to their direct connection to the blade, resulting in less power loss and quieter operation. Belt drive motors, while typically more affordable and easier to repair, may experience slippage and reduced performance over time. Choosing a direct drive motor ensures consistent cutting power and longevity, making it ideal for heavy-duty food processing tasks.

Direct drive motor vs Belt drive motor for food processor Infographic

productvia.com

productvia.com