Direct drive motors in food processors offer superior power efficiency and durability by connecting the blade directly to the motor, reducing energy loss and noise. Belt drive motors provide smoother operation and better shock absorption, but often require more maintenance due to belt wear and potential slippage. Choosing between them depends on the desired balance of performance, noise level, and upkeep preferences.

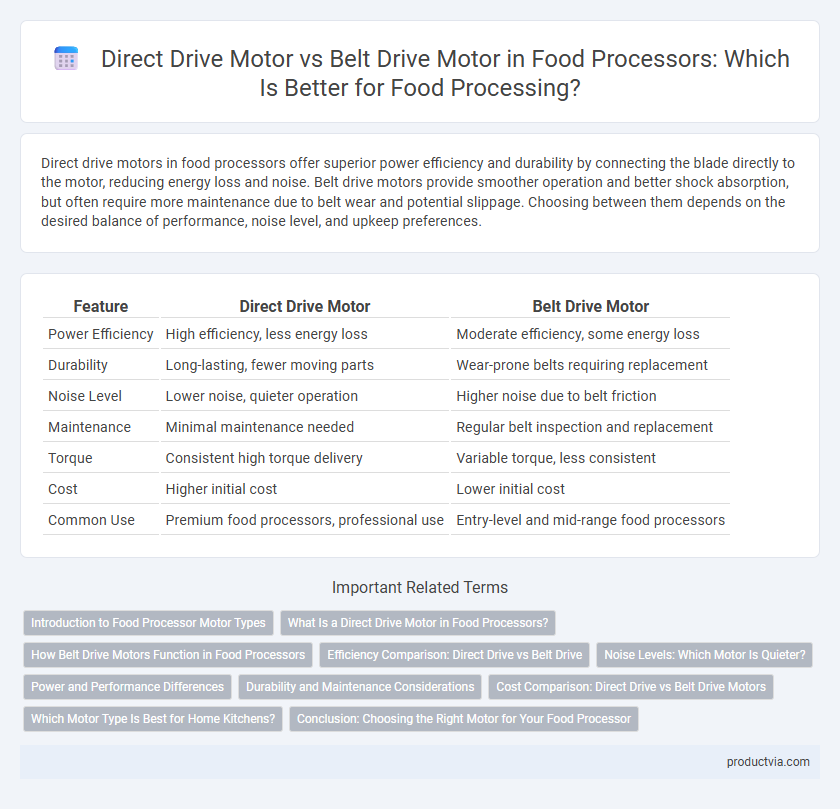

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Power Efficiency | High efficiency, less energy loss | Moderate efficiency, some energy loss |

| Durability | Long-lasting, fewer moving parts | Wear-prone belts requiring replacement |

| Noise Level | Lower noise, quieter operation | Higher noise due to belt friction |

| Maintenance | Minimal maintenance needed | Regular belt inspection and replacement |

| Torque | Consistent high torque delivery | Variable torque, less consistent |

| Cost | Higher initial cost | Lower initial cost |

| Common Use | Premium food processors, professional use | Entry-level and mid-range food processors |

Introduction to Food Processor Motor Types

Direct drive motors in food processors connect the motor shaft directly to the blade assembly, resulting in higher efficiency, reduced maintenance, and quieter operation. Belt drive motors use a flexible belt to transfer power from the motor to the blade, offering smoother speed variation and easier maintenance but potentially lower power output. Choosing between the two depends on desired performance, noise levels, and long-term durability for specific food processing tasks.

What Is a Direct Drive Motor in Food Processors?

A direct drive motor in food processors connects the motor shaft directly to the blade assembly, ensuring efficient power transfer and reduced mechanical losses. This design typically results in quieter operation, increased durability, and less maintenance compared to belt drive systems. Food processors with direct drive motors often provide consistent torque for tougher ingredients, enhancing overall performance and reliability.

How Belt Drive Motors Function in Food Processors

Belt drive motors in food processors operate by transferring power from the motor to the blade assembly through a flexible belt, which reduces direct stress on the motor and allows for smoother operation. This mechanism provides better shock absorption and quieter performance, making belt-driven food processors ideal for heavy-duty chopping and mixing tasks. However, belts may require periodic maintenance or replacement to ensure consistent power transfer and optimal functionality.

Efficiency Comparison: Direct Drive vs Belt Drive

Direct drive motors in food processors offer higher efficiency by transferring power directly from the motor to the blade assembly, minimizing energy loss and ensuring consistent performance. Belt drive motors, while typically quieter and more affordable, experience power reduction due to belt slippage and require regular maintenance to sustain optimal efficiency. Overall, direct drive systems provide superior energy efficiency and durability, making them ideal for high-performance food processing tasks.

Noise Levels: Which Motor Is Quieter?

Direct drive motors in food processors operate with less mechanical friction, resulting in significantly lower noise levels compared to belt drive motors. Belt drive systems tend to generate more vibration and noise due to the rubber belt's movement and potential wear over time. For quieter kitchen environments, choosing a food processor with a direct drive motor is the optimal solution.

Power and Performance Differences

Direct drive motors in food processors deliver superior power and performance through a direct connection to the blade, resulting in efficient energy transfer, higher torque, and smoother operation. Belt drive motors, while often quieter and less expensive, may experience power loss due to belt slippage and require more maintenance, potentially reducing blade speed and processing efficiency. Choosing a direct drive motor ensures consistent, high-performance food processing suitable for heavy-duty tasks and frequent use.

Durability and Maintenance Considerations

Direct drive motors in food processors offer superior durability due to fewer moving parts and direct coupling between the motor and blade assembly, reducing wear and tear. Belt drive motors require regular belt inspections and replacements, leading to increased maintenance demands and potential downtime. Choosing a direct drive motor enhances long-term reliability and minimizes maintenance efforts, making it ideal for frequent or heavy-duty food processing tasks.

Cost Comparison: Direct Drive vs Belt Drive Motors

Direct drive motors in food processors generally have higher upfront costs due to their integrated design and increased durability, leading to long-term savings with reduced maintenance. Belt drive motors typically cost less initially but may incur additional expenses over time from belt replacements and motor wear. Choosing between direct drive and belt drive motors involves balancing initial investment against potential maintenance and longevity costs.

Which Motor Type Is Best for Home Kitchens?

Direct drive motors in food processors offer greater efficiency and durability, making them ideal for frequent home use due to their minimal maintenance and quieter operation. Belt drive motors, while generally more affordable, tend to wear out faster and require regular belt replacements, which may be less convenient for home cooks. For home kitchens prioritizing reliability and consistent performance, direct drive motors are the preferred choice.

Conclusion: Choosing the Right Motor for Your Food Processor

Direct drive motors in food processors offer superior power and durability with less maintenance, making them ideal for heavy-duty tasks and frequent use. Belt drive motors provide quieter operation and easier replacement but may wear out faster under intensive workloads. Selecting the right motor depends on your cooking frequency and processing needs, with direct drive favored for robust performance and belt drive suited for lighter, occasional use.

Direct drive motor vs Belt drive motor for food processors Infographic

productvia.com

productvia.com