Inverter compressors adjust their speed to maintain consistent temperatures, resulting in significantly higher freezer efficiency and reduced energy consumption compared to conventional compressors that operate at a fixed speed. This variable speed technology minimizes temperature fluctuations and wear on the compressor, extending the freezer's lifespan. Consequently, freezers with inverter compressors offer a more environmentally friendly and cost-effective cooling solution.

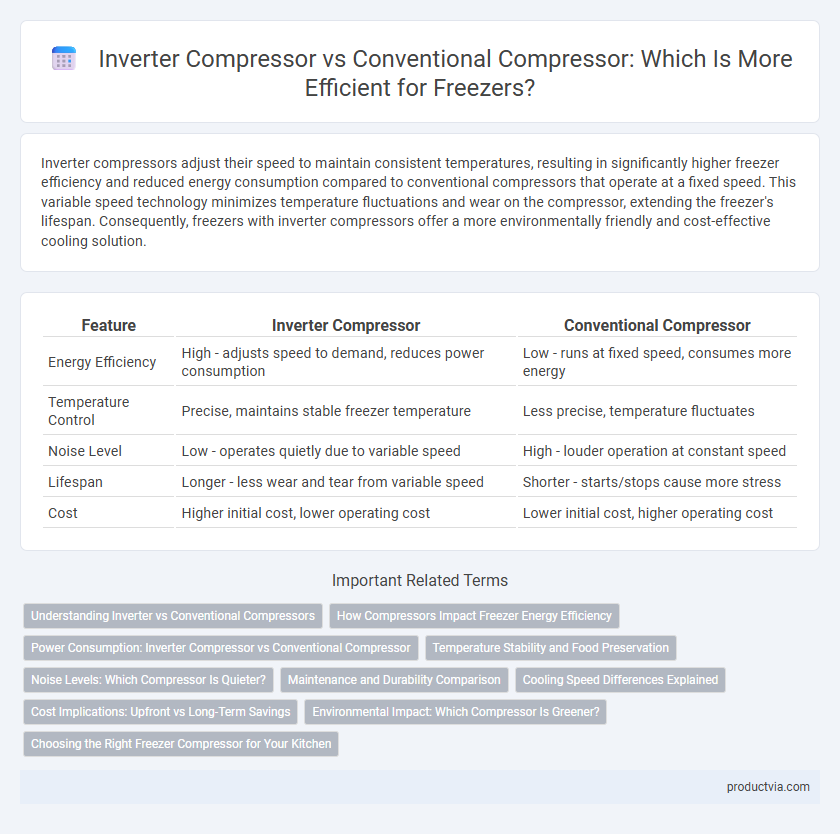

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to demand, reduces power consumption | Low - runs at fixed speed, consumes more energy |

| Temperature Control | Precise, maintains stable freezer temperature | Less precise, temperature fluctuates |

| Noise Level | Low - operates quietly due to variable speed | High - louder operation at constant speed |

| Lifespan | Longer - less wear and tear from variable speed | Shorter - starts/stops cause more stress |

| Cost | Higher initial cost, lower operating cost | Lower initial cost, higher operating cost |

Understanding Inverter vs Conventional Compressors

Inverter compressors adjust their speed based on cooling demand, resulting in energy savings and more consistent temperature control compared to conventional compressors that operate at a fixed speed, turning on and off frequently. This variable speed technology reduces power consumption by up to 30-50%, enhances freezer efficiency, and extends compressor lifespan by minimizing mechanical stress. Understanding the operational differences helps consumers choose freezers that offer improved performance, quieter operation, and lower electricity bills.

How Compressors Impact Freezer Energy Efficiency

Inverter compressors adjust their speed based on cooling demand, resulting in significant energy savings, while conventional compressors operate at a fixed speed, leading to higher energy consumption. Freezers with inverter compressors maintain a stable temperature more efficiently, reducing power usage and wear on the motor. This variable speed technology directly improves freezer energy efficiency by optimizing compressor operation and minimizing unnecessary energy expenditure.

Power Consumption: Inverter Compressor vs Conventional Compressor

Inverter compressors in freezers significantly reduce power consumption by adjusting their speed to match cooling demands, resulting in energy savings of up to 30% compared to conventional compressors that operate at a fixed speed. This variable speed technology minimizes electricity use during partial load conditions, enhancing overall efficiency. Consequently, freezers with inverter compressors offer lower operational costs and a smaller carbon footprint than those with conventional compressors.

Temperature Stability and Food Preservation

Inverter compressors provide superior temperature stability in freezers by continuously adjusting their speed to maintain consistent cooling, reducing temperature fluctuations that can compromise food quality. Conventional compressors operate on a fixed speed, causing frequent on/off cycles that create wider temperature variations, negatively impacting food preservation. The stable environment maintained by inverter compressors helps retain food texture, flavor, and nutritional value for longer periods.

Noise Levels: Which Compressor Is Quieter?

Inverter compressors for freezers operate at variable speeds, significantly reducing noise levels compared to conventional compressors that run at a constant, higher speed. By adjusting the compressor speed to the cooling demand, inverter technology minimizes the frequency and intensity of sound emissions, making it the quieter option. Conventional compressors typically produce more noise due to frequent start-stop cycles and consistent high-speed operation.

Maintenance and Durability Comparison

Inverter compressors in freezers offer enhanced durability by operating at variable speeds, reducing wear and tear compared to conventional compressors that frequently start and stop. Maintenance requirements for inverter compressors are typically lower due to their smoother operation and reduced mechanical stress, leading to fewer breakdowns and extended service intervals. Conventional compressors may require more frequent servicing and part replacements, impacting overall freezer longevity and operational cost.

Cooling Speed Differences Explained

Inverter compressors in freezers adjust their speed based on cooling demand, enabling faster and more efficient temperature reduction compared to conventional compressors that operate at fixed speeds. This variable-speed technology allows inverter compressors to reach desired cooling levels quicker, reducing energy consumption and minimizing temperature fluctuations. Studies show inverter compressors can decrease cooling time by up to 30%, enhancing freezer performance and food preservation.

Cost Implications: Upfront vs Long-Term Savings

Inverter compressors in freezers typically have a higher upfront cost compared to conventional compressors due to advanced technology and components. However, inverter compressors deliver significant long-term savings by optimizing energy consumption, reducing electricity bills by up to 30%. Conventional compressors may offer lower initial expenses but incur higher operational costs and less efficient performance over the freezer's lifespan.

Environmental Impact: Which Compressor Is Greener?

Inverter compressors for freezers significantly reduce energy consumption by adjusting their speed according to cooling demand, leading to lower greenhouse gas emissions compared to conventional compressors that run at full speed continuously. This energy efficiency translates into a smaller carbon footprint and less environmental strain over the appliance's lifecycle. Choosing an inverter compressor aligns with eco-friendly practices by minimizing electricity use and supporting sustainable energy conservation.

Choosing the Right Freezer Compressor for Your Kitchen

Inverter compressors adjust their speed based on cooling demand, offering enhanced energy efficiency and consistent temperature control for freezers. Conventional compressors operate at a fixed speed, often leading to higher energy consumption and temperature fluctuations. Choosing an inverter compressor freezer optimizes kitchen energy savings and preserves food quality by maintaining stable temperatures.

Inverter compressor vs Conventional compressor for freezer efficiency Infographic

productvia.com

productvia.com