Ceramic grinders offer superior resistance to corrosion and wear when grinding salt, ensuring a longer lifespan and consistent performance compared to steel grinders. Steel grinders can rust over time due to exposure to salt's moisture, which may affect the flavor and safety of the ground salt. Choosing a ceramic grinder for salt provides durability and maintains the purity of the seasoning without metallic contamination.

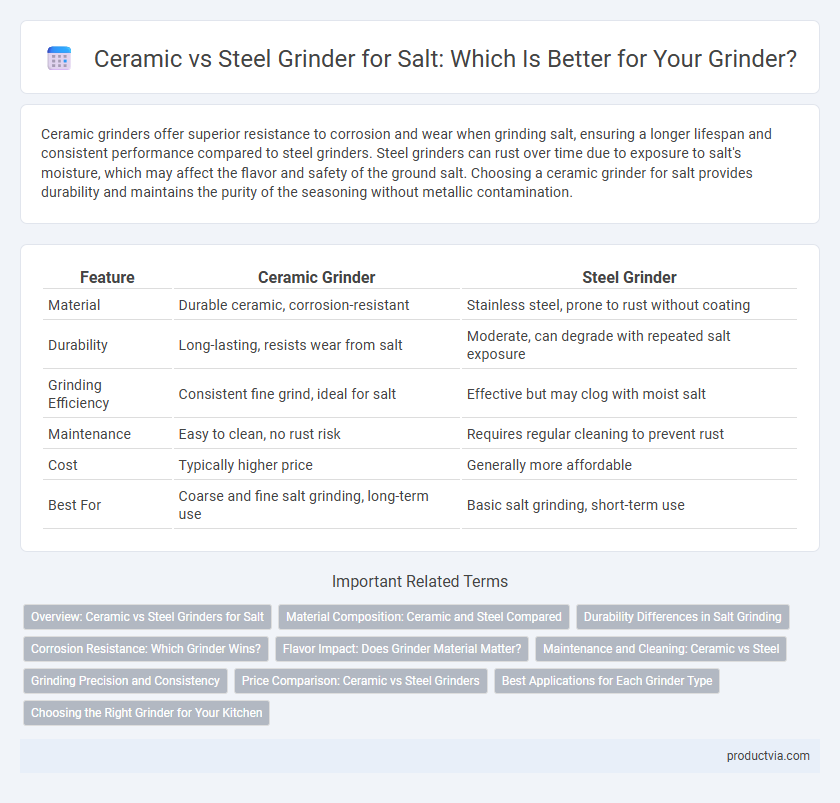

Table of Comparison

| Feature | Ceramic Grinder | Steel Grinder |

|---|---|---|

| Material | Durable ceramic, corrosion-resistant | Stainless steel, prone to rust without coating |

| Durability | Long-lasting, resists wear from salt | Moderate, can degrade with repeated salt exposure |

| Grinding Efficiency | Consistent fine grind, ideal for salt | Effective but may clog with moist salt |

| Maintenance | Easy to clean, no rust risk | Requires regular cleaning to prevent rust |

| Cost | Typically higher price | Generally more affordable |

| Best For | Coarse and fine salt grinding, long-term use | Basic salt grinding, short-term use |

Overview: Ceramic vs Steel Grinders for Salt

Ceramic grinders offer superior corrosion resistance and durability when grinding salt, preventing rust and maintaining flavor purity over time. Steel grinders, while generally stronger and more impact-resistant, can corrode or react with salt, potentially affecting taste and longevity. Selecting a ceramic grinder is often preferred for salt due to its non-reactive properties and consistent grinding performance.

Material Composition: Ceramic and Steel Compared

Ceramic grinders offer superior corrosion resistance and maintain sharpness longer due to their hard, non-metallic composition, making them ideal for corrosive salts. Steel grinders, typically made from stainless steel, provide durability and strength but may be prone to rust and require regular maintenance when exposed to moisture. The choice between ceramic and steel grinders hinges on balancing material longevity, resistance to wear, and suitability for grinding salt types.

Durability Differences in Salt Grinding

Ceramic grinders offer superior durability over steel grinders when grinding salt due to their resistance to corrosion and wear from salt crystals. Steel grinders tend to corrode or degrade faster, especially with exposure to moisture and salt's abrasive properties, reducing their lifespan. The hardness and non-reactive nature of ceramic materials ensure consistent performance and longevity in salt grinding applications.

Corrosion Resistance: Which Grinder Wins?

Ceramic grinders outperform steel grinders in corrosion resistance due to their non-metallic composition that resists rust and degradation even in humid or salty environments. Steel grinders, especially those made from non-stainless varieties, tend to corrode and affect the flavor of salt over time. For long-term durability and maintaining salt purity, ceramic grinders offer a superior solution.

Flavor Impact: Does Grinder Material Matter?

Ceramic grinders maintain the pure, unaltered flavor of salt due to their non-reactive properties, preventing any metallic taste transfer. Steel grinders, while more durable, can sometimes impart a slight metallic flavor, especially when used with moist or acidic salts. For preserving the natural salt flavor, ceramic grinders are preferred by culinary experts and chefs.

Maintenance and Cleaning: Ceramic vs Steel

Ceramic grinders for salt require less frequent cleaning due to their resistance to corrosion and staining, ensuring long-lasting performance without rust buildup. Steel grinders, while durable, need regular maintenance to prevent salt residue from causing corrosion and affecting taste. Proper cleaning with a brush and occasional disassembly are essential to maintain steel grinders' efficiency and longevity.

Grinding Precision and Consistency

Ceramic grinders offer superior grinding precision for salt due to their hardness and resistance to corrosion, maintaining sharp edges longer than steel grinders. Steel grinders may wear down more quickly, leading to uneven salt granule sizes and inconsistent seasoning in dishes. The consistent grind size of ceramic models ensures even salt distribution, enhancing flavor balance in culinary applications.

Price Comparison: Ceramic vs Steel Grinders

Ceramic grinders for salt typically cost more upfront due to their durability and resistance to corrosion, often ranging from $20 to $50. Steel grinders are generally more affordable, with prices between $10 and $30, but may require replacement sooner because metal can corrode with salt exposure. Investing in a ceramic grinder offers long-term value despite the higher initial price.

Best Applications for Each Grinder Type

Ceramic grinders excel in grinding salt due to their corrosion resistance and durability, making them ideal for coarse sea salt and Himalayan pink salt. Steel grinders perform best with regular table salt and peppercorns, offering robust grinding for harder spices. Selecting the right grinder depends on the salt type and desired grind consistency for optimal flavor release.

Choosing the Right Grinder for Your Kitchen

Ceramic grinders are highly resistant to corrosion and ideal for grinding salt due to their non-reactive properties, preserving the salt's natural flavor. Steel grinders are more durable and offer stronger grinding power but may rust over time when exposed to salt's moisture. Choosing the right grinder depends on balancing ceramic's corrosion resistance with steel's strength and durability for optimal salt grinding performance.

Ceramic grinder vs steel grinder for salt Infographic

productvia.com

productvia.com