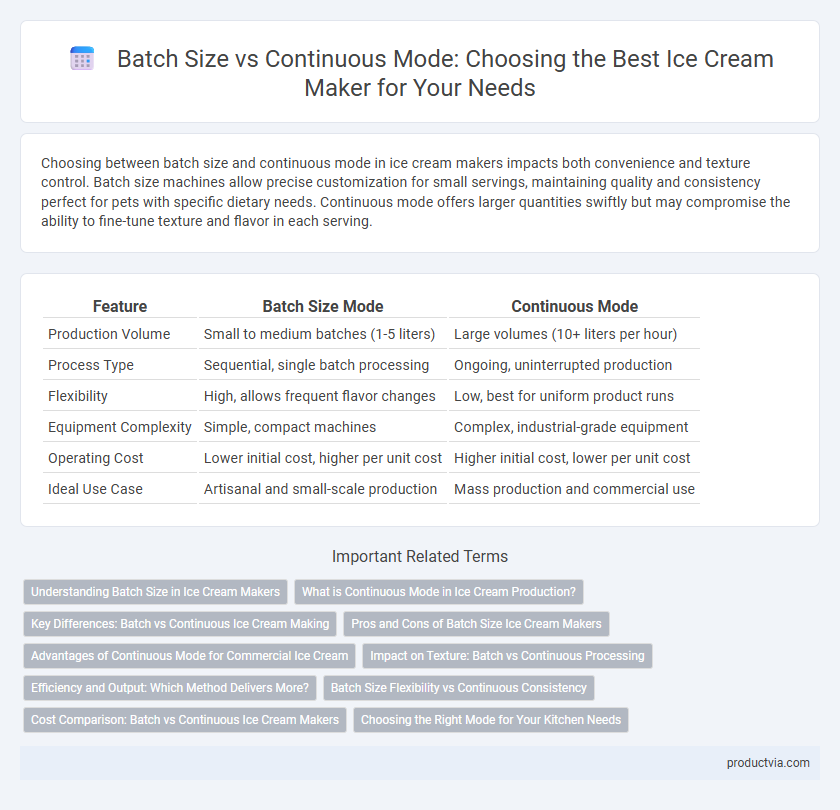

Choosing between batch size and continuous mode in ice cream makers impacts both convenience and texture control. Batch size machines allow precise customization for small servings, maintaining quality and consistency perfect for pets with specific dietary needs. Continuous mode offers larger quantities swiftly but may compromise the ability to fine-tune texture and flavor in each serving.

Table of Comparison

| Feature | Batch Size Mode | Continuous Mode |

|---|---|---|

| Production Volume | Small to medium batches (1-5 liters) | Large volumes (10+ liters per hour) |

| Process Type | Sequential, single batch processing | Ongoing, uninterrupted production |

| Flexibility | High, allows frequent flavor changes | Low, best for uniform product runs |

| Equipment Complexity | Simple, compact machines | Complex, industrial-grade equipment |

| Operating Cost | Lower initial cost, higher per unit cost | Higher initial cost, lower per unit cost |

| Ideal Use Case | Artisanal and small-scale production | Mass production and commercial use |

Understanding Batch Size in Ice Cream Makers

Batch size in ice cream makers determines the quantity of ice cream produced per cycle, directly impacting texture and flavor consistency. Smaller batch sizes allow for better control over ingredient mixing and freezing time, resulting in creamier and more evenly frozen ice cream. Understanding optimal batch size is crucial for achieving desired quality, as overfilling can cause uneven freezing and affect the churning process.

What is Continuous Mode in Ice Cream Production?

Continuous mode in ice cream production refers to a method where the ice cream mixture is processed non-stop, allowing for large-scale manufacturing without interruption. Unlike batch size methods, continuous mode enables consistent texture and quality by maintaining steady freezing and mixing conditions throughout production. This approach is ideal for commercial ice cream makers seeking high output and efficiency.

Key Differences: Batch vs Continuous Ice Cream Making

Batch ice cream makers produce limited quantities per cycle, ideal for small-scale or homemade ice cream production with greater control over texture and ingredients. Continuous ice cream machines operate nonstop, delivering large volumes suitable for commercial use, ensuring consistent product quality and higher efficiency. Key differences include production scale, processing time, and customization flexibility, with batch systems emphasizing artisanal quality and continuous systems prioritizing mass production.

Pros and Cons of Batch Size Ice Cream Makers

Batch size ice cream makers allow precise control over small quantities, ensuring optimal texture and flavor customization for each batch. They are ideal for home use or artisanal production but can be time-consuming and less efficient for large-scale manufacturing. The stationary process may result in colder products but limits output volume compared to continuous ice cream makers.

Advantages of Continuous Mode for Commercial Ice Cream

Continuous mode ice cream makers significantly increase production efficiency by allowing nonstop processing, ideal for high-demand commercial environments. This mode ensures consistent texture and quality by maintaining steady ingredient mixing and freezing conditions. Businesses benefit from reduced labor costs and minimized downtime, maximizing output to meet large-scale customer demands.

Impact on Texture: Batch vs Continuous Processing

Batch ice cream makers create smaller quantities per cycle, allowing precise control over ingredient blending and freezing, resulting in creamier texture with larger air incorporation. Continuous ice cream machines process mixtures nonstop, promoting consistent freezing and smoother texture by minimizing air pockets and maintaining uniform crystal size. Texture differences arise as batch processing enhances richness and density while continuous mode ensures homogeneity and fine crystal distribution.

Efficiency and Output: Which Method Delivers More?

Batch ice cream makers produce limited quantities per cycle, requiring downtime between batches for freezing and mixing, which affects overall efficiency and output. Continuous ice cream machines offer higher throughput by processing ingredients nonstop, ideal for large-scale production and consistent texture. For maximizing efficiency and output, continuous mode outperforms batch methods, especially in commercial settings demanding uniform quality and volume.

Batch Size Flexibility vs Continuous Consistency

Batch size flexibility in ice cream makers allows for customized portions, making it ideal for small-scale or artisanal production. Continuous mode ensures consistent texture and flavor by maintaining a steady, controlled freezing process, suitable for large-scale commercial operations. Balancing these modes depends on production goals: batch processing excels in variety and customization, while continuous mode prioritizes uniform quality and efficiency.

Cost Comparison: Batch vs Continuous Ice Cream Makers

Batch ice cream makers typically have lower upfront costs and are ideal for small-scale production, making them cost-effective for artisanal or home use. Continuous ice cream makers require higher initial investment but offer greater efficiency and lower labor costs for large-scale commercial operations by producing ice cream nonstop. Over time, continuous machines provide better cost per unit due to economies of scale, whereas batch machines incur higher costs when scaled up.

Choosing the Right Mode for Your Kitchen Needs

Batch size in ice cream makers typically ranges from 1 to 2 quarts, ideal for small kitchens or occasional use, offering precise control over ingredients and texture. Continuous mode machines handle larger volumes, producing ice cream nonstop, which suits commercial kitchens or high-demand environments seeking efficiency and consistent output. Selecting the right mode depends on your kitchen's ice cream consumption rate, space constraints, and desired production capacity to balance quality with operational flow.

Batch size vs Continuous mode for ice cream making Infographic

productvia.com

productvia.com