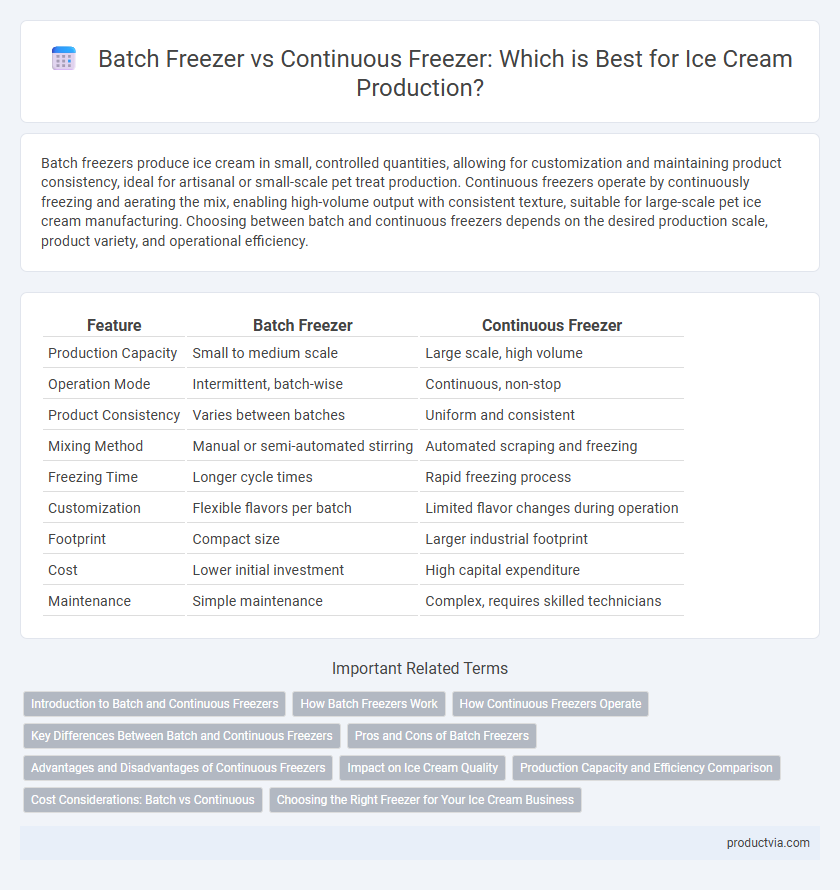

Batch freezers produce ice cream in small, controlled quantities, allowing for customization and maintaining product consistency, ideal for artisanal or small-scale pet treat production. Continuous freezers operate by continuously freezing and aerating the mix, enabling high-volume output with consistent texture, suitable for large-scale pet ice cream manufacturing. Choosing between batch and continuous freezers depends on the desired production scale, product variety, and operational efficiency.

Table of Comparison

| Feature | Batch Freezer | Continuous Freezer |

|---|---|---|

| Production Capacity | Small to medium scale | Large scale, high volume |

| Operation Mode | Intermittent, batch-wise | Continuous, non-stop |

| Product Consistency | Varies between batches | Uniform and consistent |

| Mixing Method | Manual or semi-automated stirring | Automated scraping and freezing |

| Freezing Time | Longer cycle times | Rapid freezing process |

| Customization | Flexible flavors per batch | Limited flavor changes during operation |

| Footprint | Compact size | Larger industrial footprint |

| Cost | Lower initial investment | High capital expenditure |

| Maintenance | Simple maintenance | Complex, requires skilled technicians |

Introduction to Batch and Continuous Freezers

Batch freezers produce ice cream in small, controlled quantities, ideal for artisanal and specialty products with varied flavors and textures. Continuous freezers operate by freezing and aerating the mix in a nonstop process, enabling high-volume production with consistent texture and quality. Selecting between batch and continuous freezers depends on production scale, flavor variety, and desired output efficiency in ice cream manufacturing.

How Batch Freezers Work

Batch freezers operate by simultaneously freezing and churning ice cream mixes in small quantities within a freezing chamber, using a rotating dasher to incorporate air and achieve desired texture. The process is cyclical, allowing precise control over mix composition and temperature, resulting in high-quality artisanal ice cream with distinct flavor profiles. Batch freezers are ideal for specialty ice cream production due to their flexibility and ability to handle varied ingredients without compromising texture.

How Continuous Freezers Operate

Continuous freezers operate by constantly pushing the ice cream mix through a freezing cylinder where it is rapidly frozen and simultaneously churned to incorporate air, ensuring a uniform texture. This process allows for uninterrupted production, making continuous freezers ideal for high-volume ice cream manufacturing. By maintaining precise control over freezing and overrun, continuous freezers deliver consistent product quality with increased efficiency compared to batch freezers.

Key Differences Between Batch and Continuous Freezers

Batch freezers produce ice cream in discrete quantities, allowing precise control over texture and ingredient customization. Continuous freezers operate non-stop, providing higher output rates suitable for large-scale production with consistent quality. The key differences lie in production volume, product consistency, and flexibility of recipe adjustments.

Pros and Cons of Batch Freezers

Batch freezers offer flexibility in producing small to medium quantities of ice cream with diverse flavors, allowing precise control over texture and ingredient variations. They are ideal for artisanal and specialty ice cream production but tend to have lower throughput and higher labor requirements compared to continuous freezers. The slower freezing process can enhance product quality, yet it may limit large-scale production efficiency and consistency.

Advantages and Disadvantages of Continuous Freezers

Continuous freezers offer high production efficiency by freezing and aerating ice cream in a nonstop process, significantly reducing labor costs and increasing output volume compared to batch freezers. They provide consistent product quality due to precise control over freezing parameters but require a higher initial investment and maintenance complexity. Continuous freezers are ideal for large-scale commercial ice cream manufacturers prioritizing uniformity and speed but may lack the flexibility for small batches or varied recipes.

Impact on Ice Cream Quality

Batch freezers produce smaller, artisanal batches, allowing precise control over texture and creaminess, resulting in higher-quality ice cream with air content tailored to desired consistency. Continuous freezers enable large-scale production with consistent overrun and faster freezing times but may sacrifice some creaminess and smoothness due to less individualized process control. The choice between batch and continuous freezers directly impacts ice cream quality, texture, and production scale suitability.

Production Capacity and Efficiency Comparison

Batch freezers typically produce smaller quantities of ice cream per cycle, making them ideal for artisanal or small-scale production, while continuous freezers enable high-volume output with consistent quality by processing ice cream mix non-stop. Continuous freezers offer superior efficiency by reducing labor and energy costs through automation and faster freezing times, which boosts overall production capacity significantly. The choice between batch and continuous freezers depends on the desired production scale, with continuous freezers preferred for large-scale commercial operations seeking maximum throughput.

Cost Considerations: Batch vs Continuous

Batch freezers typically involve lower initial capital investment and are ideal for small to medium-scale ice cream production, offering flexibility with varied flavors. Continuous freezers require higher upfront costs but provide greater efficiency and consistency for large-scale, high-volume manufacturing. Operational expenses for continuous freezers tend to be lower per unit due to automation and reduced labor, while batch freezers may incur higher labor and cleaning costs.

Choosing the Right Freezer for Your Ice Cream Business

Batch freezers provide flexibility by producing small, high-quality ice cream batches ideal for artisanal or specialty products, while continuous freezers offer higher efficiency and consistent output suitable for large-scale commercial production. Selecting the right freezer depends on your production volume, product variety, and desired texture control, with batch freezers excelling in customization and continuous freezers optimizing speed. Understanding your business needs ensures the freezer supports both operational goals and product quality standards in your ice cream production.

Batch freezer vs Continuous freezer for production Infographic

productvia.com

productvia.com