Timer-based shutoff in ice cream makers relies on preset durations to stop the freezing process, offering simplicity but risking under- or over-churning. Texture sensor shutoff technology monitors the consistency of the mixture in real time, ensuring optimal creaminess and preventing ice crystal formation. Choosing between these methods affects the final texture and overall quality of homemade ice cream.

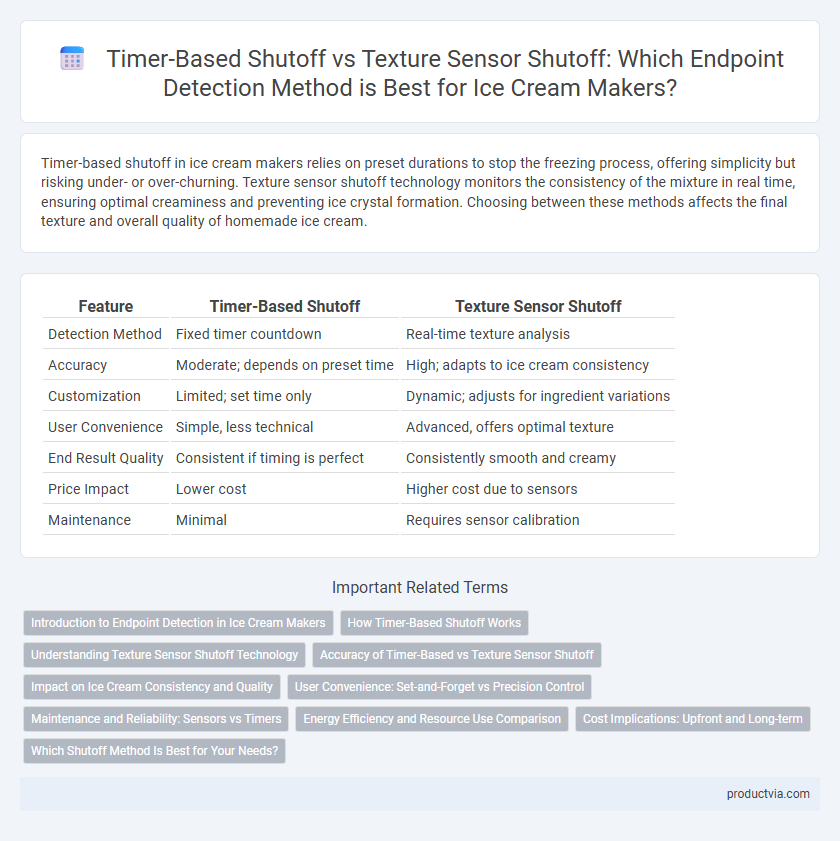

Table of Comparison

| Feature | Timer-Based Shutoff | Texture Sensor Shutoff |

|---|---|---|

| Detection Method | Fixed timer countdown | Real-time texture analysis |

| Accuracy | Moderate; depends on preset time | High; adapts to ice cream consistency |

| Customization | Limited; set time only | Dynamic; adjusts for ingredient variations |

| User Convenience | Simple, less technical | Advanced, offers optimal texture |

| End Result Quality | Consistent if timing is perfect | Consistently smooth and creamy |

| Price Impact | Lower cost | Higher cost due to sensors |

| Maintenance | Minimal | Requires sensor calibration |

Introduction to Endpoint Detection in Ice Cream Makers

Endpoint detection in ice cream makers distinguishes when the mixture reaches the desired consistency, ensuring optimal texture and preventing over-freezing. Timer-based shutoff relies on preset durations but may lead to inconsistent results due to varying ingredient temperatures and quantities. Texture sensor shutoff uses real-time monitoring of mixture firmness, providing precise control and consistently creamy outcomes.

How Timer-Based Shutoff Works

Timer-based shutoff in ice cream makers functions by running the freezing and churning process for a predetermined time set by the user or manufacturer, typically ranging from 20 to 40 minutes depending on the model. Once the timer completes, the machine automatically stops, ensuring consistent batch sizes and preventing over-freezing. This method relies on time estimation rather than actual texture or firmness, providing simplicity but less precision compared to texture sensor shutoff systems.

Understanding Texture Sensor Shutoff Technology

Texture sensor shutoff technology in ice cream makers monitors the consistency and firmness of the mixture to determine the ideal endpoint, ensuring optimal texture and creaminess. Unlike timer-based shutoff systems that rely purely on preset durations, texture sensors adjust processing time dynamically based on real-time data, preventing under or over-churning. This advanced method enhances product quality by delivering perfectly aerated ice cream tailored to specific recipes and ingredients.

Accuracy of Timer-Based vs Texture Sensor Shutoff

Timer-based shutoff in ice cream makers relies on preset durations, often leading to inconsistent results due to variations in ingredient composition and ambient temperature. Texture sensor shutoff uses real-time monitoring of ice cream consistency, providing higher accuracy by detecting the exact endpoint of desired firmness and creaminess. This sensor-driven method minimizes overchurning and freezer burn, ensuring optimal texture and quality in each batch.

Impact on Ice Cream Consistency and Quality

Timer-based shutoff in ice cream makers risks inconsistent texture due to fixed cycle durations that may not account for ingredient variations or ambient conditions. Texture sensor shutoff enhances ice cream quality by detecting optimal firmness and creaminess, ensuring a precise endpoint for smoother, creamier results. This sensor-driven method adapts to batch differences, reducing the likelihood of overfreezing or underprocessing, which directly improves overall consistency.

User Convenience: Set-and-Forget vs Precision Control

Timer-based shutoff offers user convenience through a set-and-forget approach, allowing users to program the machine and step away without monitoring. Texture sensor shutoff ensures precision control by detecting the ideal ice cream consistency in real-time, preventing overfreezing or undermixing. Users seeking effortless operation prefer timer-based models, while those prioritizing perfect texture favor texture sensors for optimal results.

Maintenance and Reliability: Sensors vs Timers

Timer-based shutoff mechanisms in ice cream makers are generally simpler and require minimal maintenance, as they rely on preset durations to stop the machine, minimizing mechanical wear. Texture sensor shutoff systems, while offering precise endpoint detection by monitoring the mixture's consistency, involve more complex electronic components that may need regular calibration and can be more prone to sensor malfunctions. Overall, timer systems offer higher reliability with less frequent maintenance, whereas texture sensors provide accuracy at the potential cost of increased upkeep.

Energy Efficiency and Resource Use Comparison

Timer-based shutoff in ice cream makers uses a preset duration to stop operation, often resulting in over-processing and unnecessary energy consumption. Texture sensor shutoff detects the precise consistency of the ice cream, optimizing energy use by stopping the machine exactly when the desired texture is reached. This sensor-driven approach reduces electricity usage and minimizes waste, enhancing overall resource efficiency during production.

Cost Implications: Upfront and Long-term

Timer-based shutoff ice cream makers generally have lower upfront costs due to simpler mechanical components, making them an affordable choice for budget-conscious consumers. Texture sensor shutoff models incur higher initial expenses due to advanced sensor technology but can prevent overchurning, potentially reducing ingredient waste and ensuring consistent product quality over time. Long-term cost implications favor texture sensors by minimizing the risk of texture deterioration and machine wear, whereas timer-based models may require more frequent monitoring and potential ingredient loss.

Which Shutoff Method Is Best for Your Needs?

Timer-based shutoff in ice cream makers offers straightforward control by stopping the machine after a preset duration, ideal for consistent recipes requiring specific freezing times. Texture sensor shutoff dynamically monitors the mixture's consistency, providing precise results by detecting the perfect firmness, which is beneficial for users seeking optimal texture customization. Selecting the best shutoff method depends on whether you prioritize ease of use and repeatability or tailored texture precision in your homemade ice cream.

Timer-based shutoff vs Texture sensor shutoff for endpoint detection Infographic

productvia.com

productvia.com