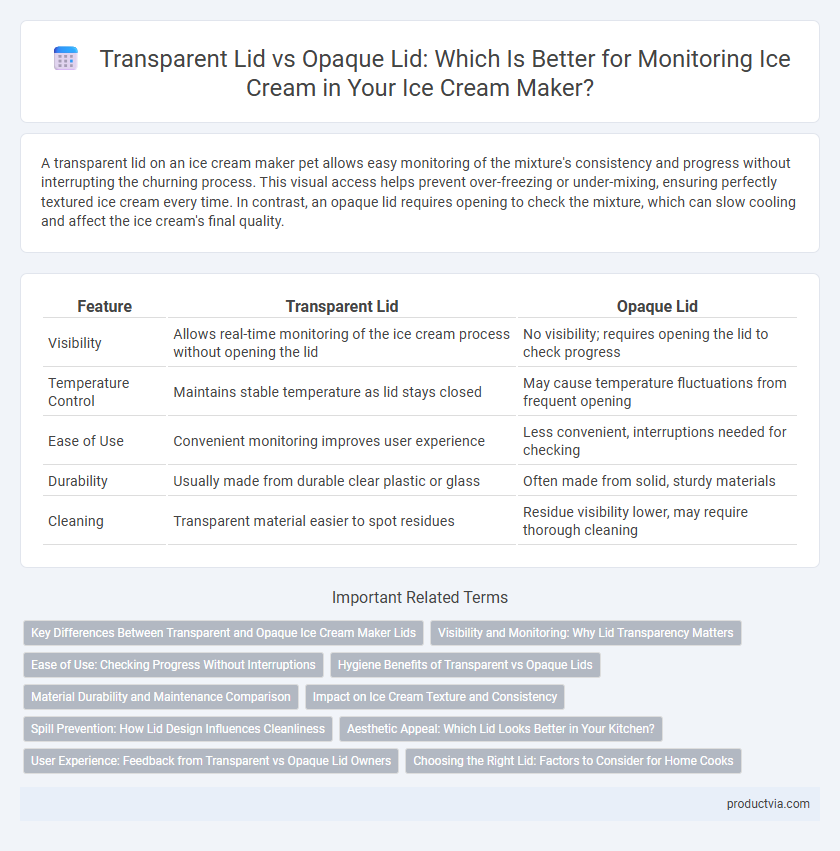

A transparent lid on an ice cream maker pet allows easy monitoring of the mixture's consistency and progress without interrupting the churning process. This visual access helps prevent over-freezing or under-mixing, ensuring perfectly textured ice cream every time. In contrast, an opaque lid requires opening to check the mixture, which can slow cooling and affect the ice cream's final quality.

Table of Comparison

| Feature | Transparent Lid | Opaque Lid |

|---|---|---|

| Visibility | Allows real-time monitoring of the ice cream process without opening the lid | No visibility; requires opening the lid to check progress |

| Temperature Control | Maintains stable temperature as lid stays closed | May cause temperature fluctuations from frequent opening |

| Ease of Use | Convenient monitoring improves user experience | Less convenient, interruptions needed for checking |

| Durability | Usually made from durable clear plastic or glass | Often made from solid, sturdy materials |

| Cleaning | Transparent material easier to spot residues | Residue visibility lower, may require thorough cleaning |

Key Differences Between Transparent and Opaque Ice Cream Maker Lids

Transparent ice cream maker lids allow real-time monitoring of the churning process, helping users track consistency without interrupting the cycle. Opaque lids require lifting to check progress, potentially affecting texture by exposing the mixture to external temperature changes. Choosing between transparent and opaque lids impacts convenience, precision, and overall ice cream quality during the freezing and mixing stages.

Visibility and Monitoring: Why Lid Transparency Matters

Transparent lids on ice cream makers significantly enhance visibility, allowing users to monitor the freezing process without interrupting it. This real-time observation ensures precise control over texture and consistency, reducing the risk of over or under-churning. Opaque lids, in contrast, limit visual access, making it harder to achieve ideal results and potentially leading to inconsistent ice cream quality.

Ease of Use: Checking Progress Without Interruptions

Transparent lids on ice cream makers allow users to monitor the churning and freezing process without opening the machine, preserving temperature and texture consistency. Opaque lids require users to pause or open the device to check progress, which can disrupt the cycle and affect the final product quality. Choosing a transparent lid enhances ease of use by providing real-time visibility, reducing guesswork and improving overall ice cream results.

Hygiene Benefits of Transparent vs Opaque Lids

Transparent lids on ice cream makers offer superior hygiene benefits by allowing users to monitor the churning process without removing the lid, reducing the risk of contamination from external particles or hands. This visibility helps maintain a cleaner environment, preventing the introduction of bacteria or dust into the mixture. In contrast, opaque lids require frequent removal to check progress, increasing exposure to potential contaminants and compromising overall hygiene.

Material Durability and Maintenance Comparison

Transparent lids on ice cream makers, typically made from durable polycarbonate or acrylic, offer clear visibility of the freezing process without opening the machine, reducing temperature fluctuations and enhancing consistency. Opaque lids, often constructed from reinforced plastic or metal, provide superior durability and resistance to scratches or discoloration, making them ideal for heavy usage but require periodic cleaning to prevent buildup since visibility is limited. Maintenance for transparent lids demands gentle cleaning techniques to avoid scratching, while opaque lids can endure more rigorous cleaning methods, extending overall lifespan and performance.

Impact on Ice Cream Texture and Consistency

A transparent lid on an ice cream maker allows continuous visual monitoring of the freezing process, enabling timely adjustments to maintain optimal churning speed and temperature, which results in a smoother texture and consistent creaminess. An opaque lid restricts visibility, increasing the risk of over-churning or under-churning, leading to ice crystals or uneven texture in the final product. Consistent agitation under precise conditions is critical for achieving the ideal ice cream texture, making lid transparency a significant factor in quality control during production.

Spill Prevention: How Lid Design Influences Cleanliness

Transparent lids on ice cream makers enable users to monitor the churning process without opening the machine, significantly reducing the risk of spills and maintaining cleanliness. Opaque lids require opening to check progress, increasing the likelihood of splatters and messes around the machine. Effective spill prevention is enhanced by transparent lids that seal tightly while allowing continuous visual oversight during mixing.

Aesthetic Appeal: Which Lid Looks Better in Your Kitchen?

Transparent lids on ice cream makers provide clear visibility of the churning process, adding a dynamic and interactive element to your kitchen countertop while showcasing the creamy texture as it forms. Opaque lids, often designed with sleek, minimalist finishes, contribute to a clean and cohesive aesthetic, blending seamlessly with modern kitchen appliances without drawing excessive attention. Choosing between transparent and opaque lids depends on whether you prioritize visual engagement during ice cream making or a more understated and polished look for your kitchen decor.

User Experience: Feedback from Transparent vs Opaque Lid Owners

Transparent lids on ice cream makers significantly enhance user experience by allowing continuous monitoring of the churning process without interrupting operation, resulting in better texture control and consistency. Owners of transparent lid models report higher satisfaction due to the visibility of ice cream progress, which reduces guesswork and prevents over-processing. In contrast, users with opaque lids often rely on timed estimates and frequent pauses, which can interrupt freezing cycles and affect the final quality.

Choosing the Right Lid: Factors to Consider for Home Cooks

Transparent lids on ice cream makers allow home cooks to easily monitor the churning process, ensuring optimal texture and consistency without interrupting the cycle. Opaque lids, while often more durable and sometimes better insulated, require opening the machine to check progress, risking heat loss and affecting the final result. When choosing the right lid, prioritize visibility for precise control or insulation for maintaining temperature, depending on your specific needs and usage frequency.

Transparent lid vs Opaque lid for monitoring Infographic

productvia.com

productvia.com