Direct drive ice cream maker motors are generally more efficient and durable because the motor connects directly to the mixing mechanism, reducing energy loss and maintenance needs. Belt drive systems can absorb shocks and reduce noise but often sacrifice some efficiency due to slipping or belt wear over time. Choosing direct drive models ensures smoother operation and longer-lasting performance for pet-friendly ice cream makers.

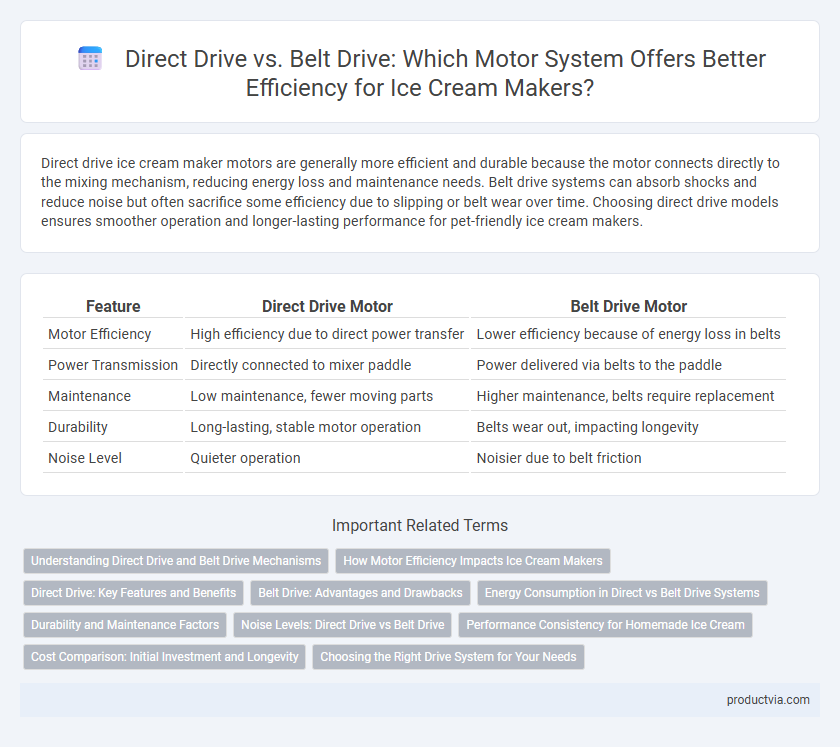

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Motor Efficiency | High efficiency due to direct power transfer | Lower efficiency because of energy loss in belts |

| Power Transmission | Directly connected to mixer paddle | Power delivered via belts to the paddle |

| Maintenance | Low maintenance, fewer moving parts | Higher maintenance, belts require replacement |

| Durability | Long-lasting, stable motor operation | Belts wear out, impacting longevity |

| Noise Level | Quieter operation | Noisier due to belt friction |

Understanding Direct Drive and Belt Drive Mechanisms

Direct drive ice cream makers connect the motor directly to the mixing bowl, offering higher motor efficiency and reduced energy loss by eliminating intermediary components. Belt drive systems utilize a belt to transfer power from the motor to the paddle, introducing slight energy dissipation but providing quieter operation and easier maintenance. Understanding the mechanical differences helps in selecting an ice cream maker that balances motor efficiency with noise levels and durability.

How Motor Efficiency Impacts Ice Cream Makers

Direct drive ice cream makers typically offer higher motor efficiency by minimizing energy loss through fewer moving parts, resulting in faster freezing times and more consistent texture. Belt drive systems, while often quieter, can experience energy loss due to friction and slippage, which may reduce overall motor efficiency and prolong the mixing process. Improved motor efficiency in ice cream makers leads to lower power consumption, enhanced durability, and optimal performance during the churning and freezing cycles.

Direct Drive: Key Features and Benefits

Direct drive ice cream makers feature a motor directly connected to the mixing paddle, enhancing motor efficiency by minimizing energy loss and mechanical complexity. This design reduces noise levels and maintenance needs, ensuring consistent performance and durability over time. High torque output in direct drive systems enables faster freezing and smoother texture in ice cream production.

Belt Drive: Advantages and Drawbacks

Belt drive ice cream makers offer quieter operation and reduced motor wear by absorbing vibrations and distributing load more evenly, leading to longer motor lifespan and smoother performance. However, belt drive systems may require periodic belt maintenance or replacement, and can experience slight efficiency losses due to belt slippage compared to direct drive motors. This trade-off between noise reduction and maintenance needs makes belt drive models ideal for users prioritizing quieter, gentler motor operation over maximum torque efficiency.

Energy Consumption in Direct vs Belt Drive Systems

Direct drive ice cream makers offer superior motor efficiency by transferring power directly from the motor to the mixing mechanism, resulting in lower energy consumption compared to belt drive systems. Belt drive ice cream makers exhibit higher energy losses due to friction and slippage between the motor and the mixer, leading to increased electricity usage during operation. Studies show that direct drive systems can reduce energy consumption by up to 20%, making them more cost-effective and eco-friendly for frequent ice cream production.

Durability and Maintenance Factors

Direct drive ice cream makers feature motors connected directly to the mixing paddle, resulting in higher efficiency, reduced energy loss, and prolonged motor lifespan due to fewer moving parts. Belt drive models involve a belt linking the motor to the paddle, which can cause slippage, increased wear, and require regular belt replacements or adjustments, impacting overall durability. Maintenance for direct drive systems is generally simpler and less frequent, making them more reliable and cost-effective for long-term use.

Noise Levels: Direct Drive vs Belt Drive

Direct drive ice cream makers operate with the motor directly connected to the mixing paddle, resulting in lower noise levels due to fewer moving parts and no belt slippage. Belt drive models generate more noise as the motor powers the paddle through a belt system, causing friction and vibration. Noise-sensitive users often prefer direct drive machines for their quieter operation during ice cream churning.

Performance Consistency for Homemade Ice Cream

Direct drive ice cream makers deliver superior motor efficiency by connecting the motor shaft directly to the mixing paddle, ensuring consistent power transfer and uniform freezing. Belt drive systems may experience slippage or wear over time, leading to inconsistent mixing speed and uneven ice cream texture. For homemade ice cream enthusiasts seeking reliable performance and smooth, creamy results, direct drive models offer enhanced durability and maintaining consistent motor output throughout the churning process.

Cost Comparison: Initial Investment and Longevity

Direct drive ice cream makers typically have a higher initial investment due to their robust motor design, but they offer greater motor efficiency and longevity, reducing long-term replacement costs. Belt drive models often come with a lower upfront price but require more frequent maintenance and belt replacements, leading to higher cumulative expenses over time. Choosing direct drive systems ensures better cost-effectiveness through durable performance and reduced operational downtime.

Choosing the Right Drive System for Your Needs

Direct drive ice cream makers offer higher motor efficiency with less energy loss, providing faster and more consistent freezing performance ideal for frequent or commercial use. Belt drive systems tend to be quieter and easier to repair, making them suitable for occasional home use where simplicity and lower cost are priorities. Assess your usage frequency and maintenance preferences to choose between the robust power of direct drive and the user-friendly design of belt drive mechanisms.

Direct Drive vs Belt Drive for Motor Efficiency Infographic

productvia.com

productvia.com