A transparent lid on an ice cream maker pet allows you to monitor the churning process without interrupting it, ensuring your dessert reaches the perfect consistency. In contrast, an opaque lid requires opening to check progress, which can disrupt the temperature and texture. Choosing a transparent lid enhances convenience and precision for creating ideal homemade ice cream.

Table of Comparison

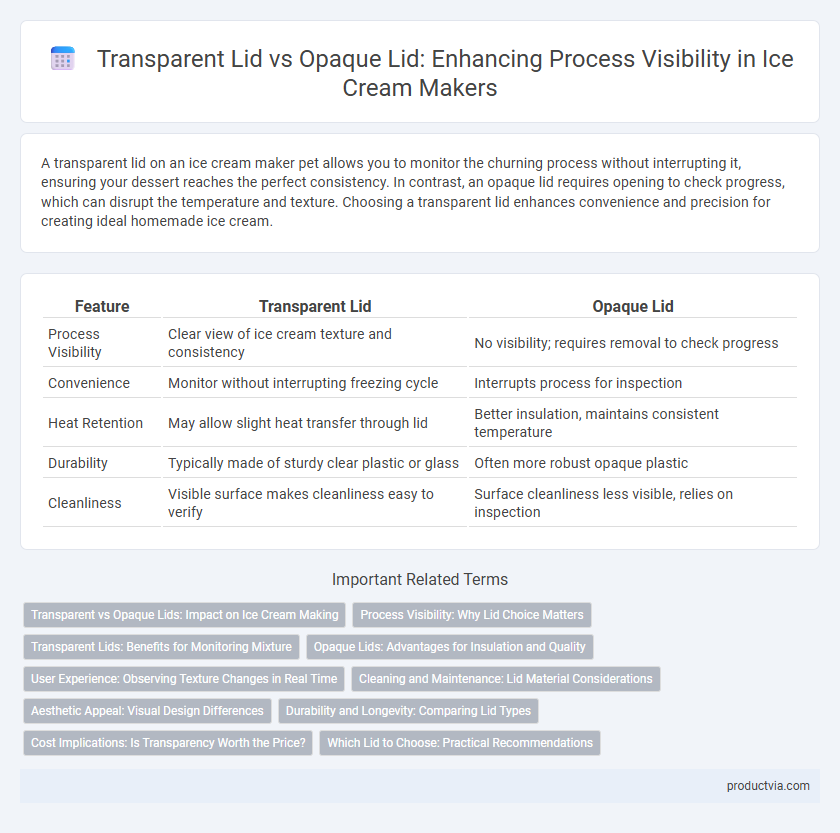

| Feature | Transparent Lid | Opaque Lid |

|---|---|---|

| Process Visibility | Clear view of ice cream texture and consistency | No visibility; requires removal to check progress |

| Convenience | Monitor without interrupting freezing cycle | Interrupts process for inspection |

| Heat Retention | May allow slight heat transfer through lid | Better insulation, maintains consistent temperature |

| Durability | Typically made of sturdy clear plastic or glass | Often more robust opaque plastic |

| Cleanliness | Visible surface makes cleanliness easy to verify | Surface cleanliness less visible, relies on inspection |

Transparent vs Opaque Lids: Impact on Ice Cream Making

Transparent lids on ice cream makers allow users to monitor the churning process without interrupting, ensuring optimal texture and consistency by observing the mixture's thickening. Opaque lids, while potentially better at insulating and maintaining temperature, limit visual access, which can lead to over-churning or under-churning if timing is misjudged. Choosing between transparent and opaque lids balances the need for process visibility with temperature control, directly impacting the quality of homemade ice cream.

Process Visibility: Why Lid Choice Matters

Transparent lids on ice cream makers enable constant monitoring of the churning process, allowing users to observe texture and consistency changes without interrupting cooling. Process visibility ensures precise timing, reducing the risk of over-freezing or under-churning, which directly impacts the final product's creaminess and smoothness. In contrast, opaque lids require opening the machine, causing temperature fluctuations that can impair ice cream quality and consistency.

Transparent Lids: Benefits for Monitoring Mixture

Transparent lids on ice cream makers offer clear advantages for closely monitoring the churning process, allowing users to observe the mixture's texture and consistency without interrupting. This visibility ensures optimal timing for ingredient additions and prevents overmixing, enhancing the final product's quality. Manufacturers often design transparent lids with durable, food-grade materials that resist fogging, ensuring a clear view throughout the freezing cycle.

Opaque Lids: Advantages for Insulation and Quality

Opaque lids on ice cream makers offer superior insulation, helping maintain consistent temperatures essential for smooth, creamy texture development. Their design minimizes heat transfer and light exposure, reducing the risk of ingredient degradation and crystal formation. This insulation advantage results in higher quality ice cream with improved taste and texture.

User Experience: Observing Texture Changes in Real Time

A transparent lid on an ice cream maker enhances user experience by allowing real-time observation of the texture and consistency changes during the churning process. This visibility helps users determine the perfect moment to stop, ensuring ideal creaminess and preventing over-churning. In contrast, opaque lids obscure the view, making it challenging to monitor progress without stopping the machine.

Cleaning and Maintenance: Lid Material Considerations

Transparent lids on ice cream makers enhance process visibility, allowing users to monitor churning without lifting the lid, reducing contamination risk and cleaning frequency. Opaque lids, often made of more durable materials, may resist stains and scratches better, simplifying maintenance but requiring lid removal for process checks. Selecting between transparent and opaque lids impacts cleaning routines and user convenience by balancing visual access with material resilience.

Aesthetic Appeal: Visual Design Differences

Transparent lids on ice cream makers enhance process visibility by allowing users to monitor the churning without interrupting the operation, offering a sleek, modern aesthetic that appeals to tech-savvy consumers. Opaque lids often provide a more traditional or minimalist design, blending seamlessly with various kitchen styles while concealing the ice cream-making process. The choice between transparent and opaque lids influences both the functional experience and the visual impact, with transparent options showcasing dynamic activity and opaque designs emphasizing subtle elegance.

Durability and Longevity: Comparing Lid Types

Transparent lids on ice cream makers offer excellent process visibility, allowing users to monitor the mixture without interrupting freezing, but they are often made from less durable plastics that may scratch or crack over time. Opaque lids, typically constructed from sturdier materials such as reinforced plastic or metal, provide superior durability and longer lifespan under frequent use but sacrifice visual access during the churning process. For longevity, opaque lids are preferred in commercial or heavy-use settings, while transparent lids suit casual users prioritizing convenience and visual tracking.

Cost Implications: Is Transparency Worth the Price?

Transparent lids on ice cream makers allow real-time monitoring of the churning process, enhancing user experience but often come at a higher price point than opaque lids. Opaque lids, while more cost-effective, limit visibility and may require interrupting the cycle to check progress, potentially affecting consistency. Evaluating whether the premium for transparency justifies improved process visibility depends on user preference and budget constraints.

Which Lid to Choose: Practical Recommendations

Choosing between a transparent lid and an opaque lid for an ice cream maker depends on the importance of process visibility versus insulation. Transparent lids allow monitoring of the churning process without interrupting it, helping to achieve the desired texture more precisely. Opaque lids often provide better insulation, maintaining consistent temperature and speeding up freezing, making them ideal for users prioritizing efficiency over visual access.

Transparent Lid vs Opaque Lid for Process Visibility Infographic

productvia.com

productvia.com