Chill-resistant housing in ice cream makers provides superior insulation compared to standard housing, maintaining a consistently low temperature for smoother, creamier ice cream results. This enhanced insulation reduces the need for frequent refreezing, making the ice cream maker more efficient and convenient. The improved temperature retention also minimizes energy consumption, extending the machine's lifespan and boosting overall performance.

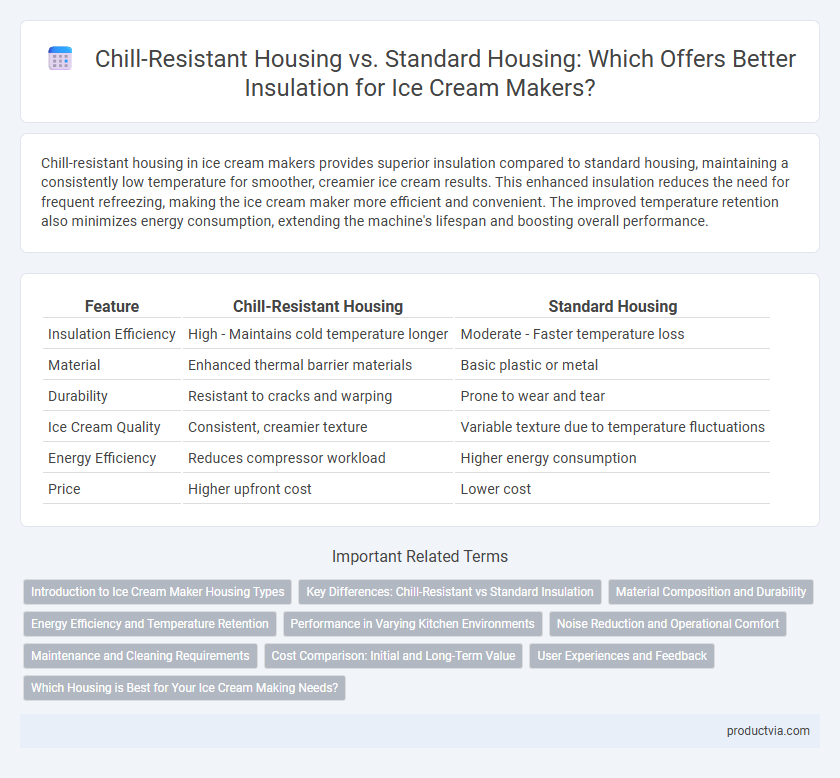

Table of Comparison

| Feature | Chill-Resistant Housing | Standard Housing |

|---|---|---|

| Insulation Efficiency | High - Maintains cold temperature longer | Moderate - Faster temperature loss |

| Material | Enhanced thermal barrier materials | Basic plastic or metal |

| Durability | Resistant to cracks and warping | Prone to wear and tear |

| Ice Cream Quality | Consistent, creamier texture | Variable texture due to temperature fluctuations |

| Energy Efficiency | Reduces compressor workload | Higher energy consumption |

| Price | Higher upfront cost | Lower cost |

Introduction to Ice Cream Maker Housing Types

Ice cream maker housing types play a critical role in maintaining optimal temperature for efficient freezing. Chill-resistant housing features advanced insulation materials that prevent heat transfer, ensuring consistent cold retention during the ice cream making process. Standard housing offers basic insulation suitable for casual use but may not maintain temperature stability under frequent operation or warm ambient conditions.

Key Differences: Chill-Resistant vs Standard Insulation

Chill-resistant housing in ice cream makers offers superior thermal insulation by utilizing advanced materials that minimize heat transfer, ensuring consistent freezing cycles and faster preparation times. Standard housing typically uses basic insulation, which can result in temperature fluctuations and longer freezing durations. The enhanced insulation of chill-resistant models not only improves energy efficiency but also maintains optimal ice cream texture by preventing unwanted warming during the churning process.

Material Composition and Durability

Chill-resistant housing for ice cream makers typically features high-grade polymer composites with enhanced thermal insulation properties, providing superior cold retention compared to standard ABS plastic housing. The advanced material composition improves durability by resisting cracking and warping under temperature variations, extending the appliance's lifespan. Standard housing, while cost-effective, often lacks these specialized properties, making it more susceptible to wear and reduced insulation efficiency over time.

Energy Efficiency and Temperature Retention

Chill-resistant housing in ice cream makers significantly improves energy efficiency by maintaining lower internal temperatures with less power consumption compared to standard housing. This advanced insulation technology enhances temperature retention, preventing heat transfer and ensuring consistent freezing performance during the churning process. As a result, ice cream makers with chill-resistant housing deliver faster freeze cycles and reduce overall energy costs, making them superior to those with standard housing designs.

Performance in Varying Kitchen Environments

Chill-resistant housing in ice cream makers enhances insulation by maintaining consistent internal temperatures even in warmer or fluctuating kitchen environments, improving freezing performance and reducing cycle times. Standard housing offers basic insulation but may struggle to keep the freezing bowl cold in high ambient temperatures, potentially affecting texture and consistency. Therefore, ice cream makers with chill-resistant housing deliver more reliable results across diverse kitchen conditions.

Noise Reduction and Operational Comfort

Chill-resistant housing in ice cream makers provides superior insulation that minimizes internal temperature fluctuations, reducing the compressor's workload and operational noise. This enhanced insulation translates to quieter performance compared to standard housing, which often allows more heat exchange and generates louder motor sounds. Improved noise reduction in chill-resistant models contributes to greater operational comfort, making them ideal for home use or small commercial settings where a peaceful environment is preferred.

Maintenance and Cleaning Requirements

Chill-resistant housing in ice cream makers offers enhanced insulation that reduces condensation buildup, significantly minimizing maintenance efforts compared to standard housing. Its smooth, non-porous surfaces facilitate easier cleaning, helping to prevent mold and bacterial growth. Standard housing, often prone to moisture retention, requires more frequent and intensive cleaning to maintain hygienic conditions and optimal performance.

Cost Comparison: Initial and Long-Term Value

Chill-resistant housing for ice cream makers typically involves higher initial costs due to advanced insulation materials, offering superior temperature retention compared to standard housing. Over the long term, this improved insulation reduces energy consumption and lowers operational expenses, delivering better overall value despite the upfront investment. Standard housing presents a more budget-friendly option initially but may lead to increased electricity costs and less efficient cooling performance over time.

User Experiences and Feedback

Chill-resistant housing in ice cream makers significantly improves insulation by maintaining a lower internal temperature longer, resulting in creamier and smoother ice cream according to user feedback. Customers report fewer interruptions during the freezing cycle and better consistency compared to standard housing, which tends to lose cold quickly and requires more frequent refreezing. Enhanced energy efficiency and reduced noise levels in chill-resistant models contribute to a more convenient and satisfying ice cream-making experience.

Which Housing is Best for Your Ice Cream Making Needs?

Chill-resistant housing provides superior insulation by minimizing temperature fluctuations, ensuring a consistently cold environment essential for smooth, creamy ice cream texture. Standard housing offers basic insulation but may allow more heat transfer, potentially compromising freezing efficiency during long churning cycles. Choose chill-resistant housing for optimal temperature control and quality results, especially in warmer climates or extended use.

Chill-resistant housing vs Standard housing for insulation Infographic

productvia.com

productvia.com