Copper coils in induction stove pets offer superior electrical conductivity and heat transfer efficiency, resulting in faster and more consistent cooking performance. Aluminum coils, while more cost-effective and lightweight, have lower conductivity, which can lead to uneven heating and reduced overall efficiency. Choosing copper coils enhances durability and energy savings, making them a preferred option for high-performance induction cooking elements.

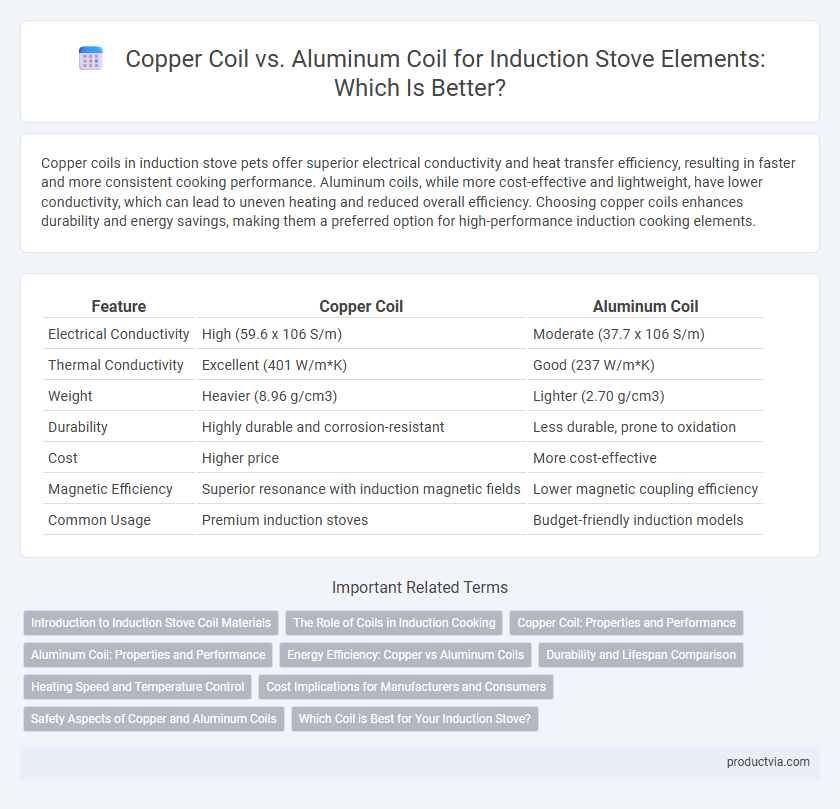

Table of Comparison

| Feature | Copper Coil | Aluminum Coil |

|---|---|---|

| Electrical Conductivity | High (59.6 x 106 S/m) | Moderate (37.7 x 106 S/m) |

| Thermal Conductivity | Excellent (401 W/m*K) | Good (237 W/m*K) |

| Weight | Heavier (8.96 g/cm3) | Lighter (2.70 g/cm3) |

| Durability | Highly durable and corrosion-resistant | Less durable, prone to oxidation |

| Cost | Higher price | More cost-effective |

| Magnetic Efficiency | Superior resonance with induction magnetic fields | Lower magnetic coupling efficiency |

| Common Usage | Premium induction stoves | Budget-friendly induction models |

Introduction to Induction Stove Coil Materials

Copper coils in induction stove elements offer superior electrical conductivity, enhancing energy efficiency and heating speed compared to aluminum coils. Aluminum coils provide a lightweight, cost-effective alternative but tend to have lower thermal conductivity and durability. Selecting the appropriate coil material significantly affects the induction cooktop's performance, heat distribution, and lifespan.

The Role of Coils in Induction Cooking

Copper coils provide superior electrical conductivity and efficient heat transfer in induction stoves, enabling faster and more precise cooking performance. Aluminum coils offer a lightweight and cost-effective alternative but have lower conductivity, which can result in less efficient energy transfer and slower heating times. The choice of coil material directly impacts the induction element's responsiveness, energy efficiency, and overall cooking experience.

Copper Coil: Properties and Performance

Copper coils in induction stoves offer superior electrical conductivity, enhancing energy efficiency and heat generation speed compared to aluminum coils. Their excellent thermal conductivity ensures uniform heating, leading to precise temperature control and reducing hotspots. Copper's durability and resistance to oxidation also promote longer coil lifespan and consistent performance under high-frequency electromagnetic fields.

Aluminum Coil: Properties and Performance

Aluminum coils in induction stoves offer excellent thermal conductivity and lightweight properties, enhancing energy efficiency and rapid heat transfer during cooking. Their corrosion resistance and flexibility contribute to durability and consistent performance in high-frequency electromagnetic fields. Compared to copper, aluminum coils provide cost-effective manufacturing with slightly lower electrical conductivity but maintain reliable induction heating capabilities in modern stove designs.

Energy Efficiency: Copper vs Aluminum Coils

Copper coils in induction stoves exhibit superior energy efficiency due to their high electrical conductivity, allowing rapid and consistent heat transfer with minimal energy loss. Aluminum coils, while lighter and less expensive, have lower conductivity, resulting in slower heating and increased energy consumption. Opting for copper coil induction elements enhances overall stove performance and reduces electricity usage.

Durability and Lifespan Comparison

Copper coils in induction stoves offer superior durability and a longer lifespan due to their high thermal conductivity and resistance to corrosion, which ensures consistent heating performance over time. Aluminum coils, while more cost-effective, tend to degrade faster under frequent heating cycles and are more prone to oxidation, reducing their overall lifespan. Investing in a copper coil induction element results in fewer replacements and better long-term reliability for high-performance cooking appliances.

Heating Speed and Temperature Control

Copper coils in induction stoves offer superior heating speed due to their higher electrical conductivity compared to aluminum coils, enabling rapid and efficient energy transfer. Copper's enhanced thermal conductivity also provides more precise temperature control, allowing consistent and stable cooking performance. Aluminum coils, while cost-effective, deliver slower heat-up times and less accurate temperature regulation, making copper the preferred choice for high-performance induction elements.

Cost Implications for Manufacturers and Consumers

Copper coils offer superior electrical conductivity and durability for induction stove elements but come with higher manufacturing costs, impacting the final consumer price. Aluminum coils provide a cost-effective alternative with lower material expenses and lighter weight, though they may require more frequent replacement due to reduced lifespan. Manufacturers must balance these factors to optimize performance while maintaining competitive pricing for consumers.

Safety Aspects of Copper and Aluminum Coils

Copper coils in induction stoves offer superior electrical conductivity and heat resistance, reducing the risk of overheating and ensuring safer operation under high temperatures. Aluminum coils, while lightweight and cost-effective, have lower thermal conductivity and are more prone to oxidation, which can compromise insulation and increase the likelihood of electrical faults. The enhanced durability and stability of copper coils make them a safer choice for induction elements, minimizing fire hazards and prolonging appliance lifespan.

Which Coil is Best for Your Induction Stove?

Copper coils offer superior electrical conductivity and heat transfer efficiency, making them ideal for induction stove elements that require rapid and consistent heating. Aluminum coils, while more cost-effective and lightweight, have lower conductivity, which can result in slower heating and reduced energy efficiency. For optimal performance and durability in induction stoves, copper coils are generally the best choice.

Copper coil vs Aluminum coil for induction element Infographic

productvia.com

productvia.com