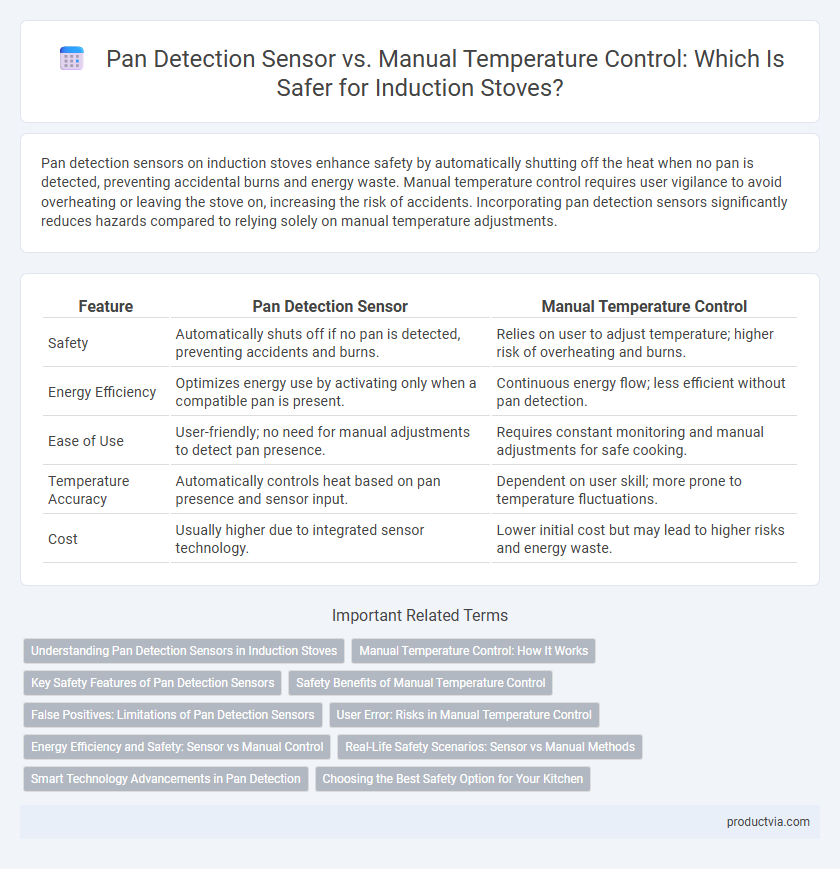

Pan detection sensors on induction stoves enhance safety by automatically shutting off the heat when no pan is detected, preventing accidental burns and energy waste. Manual temperature control requires user vigilance to avoid overheating or leaving the stove on, increasing the risk of accidents. Incorporating pan detection sensors significantly reduces hazards compared to relying solely on manual temperature adjustments.

Table of Comparison

| Feature | Pan Detection Sensor | Manual Temperature Control |

|---|---|---|

| Safety | Automatically shuts off if no pan is detected, preventing accidents and burns. | Relies on user to adjust temperature; higher risk of overheating and burns. |

| Energy Efficiency | Optimizes energy use by activating only when a compatible pan is present. | Continuous energy flow; less efficient without pan detection. |

| Ease of Use | User-friendly; no need for manual adjustments to detect pan presence. | Requires constant monitoring and manual adjustments for safe cooking. |

| Temperature Accuracy | Automatically controls heat based on pan presence and sensor input. | Dependent on user skill; more prone to temperature fluctuations. |

| Cost | Usually higher due to integrated sensor technology. | Lower initial cost but may lead to higher risks and energy waste. |

Understanding Pan Detection Sensors in Induction Stoves

Pan detection sensors in induction stoves enhance safety by automatically detecting the presence and size of cookware, preventing the stove from heating when no pan is present or if the pan is incompatible. This technology reduces the risk of burns and energy waste compared to manual temperature control, which relies solely on user input without verifying cookware presence. Understanding how pan detection sensors work helps users appreciate the advanced safety features that make induction cooking more efficient and secure.

Manual Temperature Control: How It Works

Manual temperature control in induction stoves uses precise power adjustment to regulate heat output, enhancing safety by preventing overheating and reducing the risk of burns or fire hazards. Unlike pan detection sensors that only activate heating when suitable cookware is present, manual control allows users to set and maintain specific temperatures for cooking precision. This method ensures consistent heat levels, providing better protection against accidents caused by unexpected temperature spikes.

Key Safety Features of Pan Detection Sensors

Pan detection sensors enhance safety by automatically detecting the presence and size of cookware, preventing the induction stove from heating when no pan or an incompatible pan is present. This technology minimizes the risk of burns, fires, and energy waste by disabling the heating element if the pan is removed or improperly placed. In contrast, manual temperature control relies solely on user input, lacking the automatic safety cut-off that pan detection sensors provide, making pan detection a crucial feature for preventing accidents and ensuring safer cooking environments.

Safety Benefits of Manual Temperature Control

Manual temperature control on induction stoves offers enhanced safety by allowing users to set precise heat levels, reducing the risk of overheating and potential burns. Unlike pan detection sensors, which only detect the presence of cookware, manual control ensures consistent temperature management even with varying pan types. This direct heat regulation minimizes accidental fires and promotes safer cooking environments.

False Positives: Limitations of Pan Detection Sensors

Pan detection sensors in induction stoves enhance safety by automatically shutting off heat when no cookware is detected, reducing burn risks and energy waste. However, these sensors can generate false positives, mistakenly turning off the stove when using incompatible or thin cookware, leading to frustration and interrupted cooking. Manual temperature control offers consistent heat management without detection errors but requires careful user attention to prevent overheating or accidents.

User Error: Risks in Manual Temperature Control

Pan detection sensors on induction stoves significantly reduce risks associated with user error by automatically identifying the presence and compatibility of cookware, preventing accidental overheating or energy waste. Manual temperature control relies heavily on user awareness and precision, increasing the likelihood of setting incorrect heat levels that can lead to burns, fires, or damage to cookware. Incorporating pan detection technology enhances safety by minimizing human mistakes and ensuring optimal heat application only when appropriate cookware is detected.

Energy Efficiency and Safety: Sensor vs Manual Control

Pan detection sensors in induction stoves enhance energy efficiency by automatically activating the heating element only when a compatible pan is present, preventing unnecessary power consumption and reducing safety risks like accidental burns. Manual temperature control requires constant user attention to adjust heat levels, increasing the chance of overheating and energy waste due to prolonged heating. Sensor technology optimizes power delivery and minimizes hazards by ensuring heat is applied precisely and only when needed, offering superior safety and energy savings over manual controls.

Real-Life Safety Scenarios: Sensor vs Manual Methods

Pan detection sensors on induction stoves enhance safety by automatically shutting off heat when no pan is detected, preventing burns and fire hazards in real-life scenarios such as accidental pot removal. Manual temperature control relies on user vigilance, increasing the risk of overheating or unattended cooking, which can lead to kitchen accidents. Sensor-based systems provide a proactive safety layer, reducing human error compared to manual methods.

Smart Technology Advancements in Pan Detection

Pan detection sensors in induction stoves enhance safety by automatically regulating power supply based on the presence and size of the cookware, reducing risks of overheating or accidental burns. Manual temperature control relies on user input, increasing the chance of human error and unsafe heat levels. Smart technology advancements integrate precise pan detection with adaptive temperature adjustments, optimizing energy efficiency and preventing accidents through real-time monitoring.

Choosing the Best Safety Option for Your Kitchen

Pan detection sensors on induction stoves automatically identify the presence of cookware, preventing the stove from heating when no pan is detected, thus reducing the risk of burns and energy waste. Manual temperature control relies on user input, which can lead to overheating or unattended cooking hazards if not carefully monitored. For optimal kitchen safety, pan detection sensors provide a more reliable and user-friendly solution compared to manual temperature control, minimizing accidents and enhancing energy efficiency.

Pan detection sensor vs Manual temperature control for safety Infographic

productvia.com

productvia.com