Copper coils offer superior conductivity and durability for induction heat transfer compared to aluminum coils, ensuring more efficient and consistent heating in induction stove pots. Aluminum coils, while lighter and less expensive, have lower thermal conductivity, which can result in slower heat transfer and uneven cooking performance. The enhanced performance of copper coils makes them the preferred choice for induction stove pots aiming for optimal energy efficiency and precise temperature control.

Table of Comparison

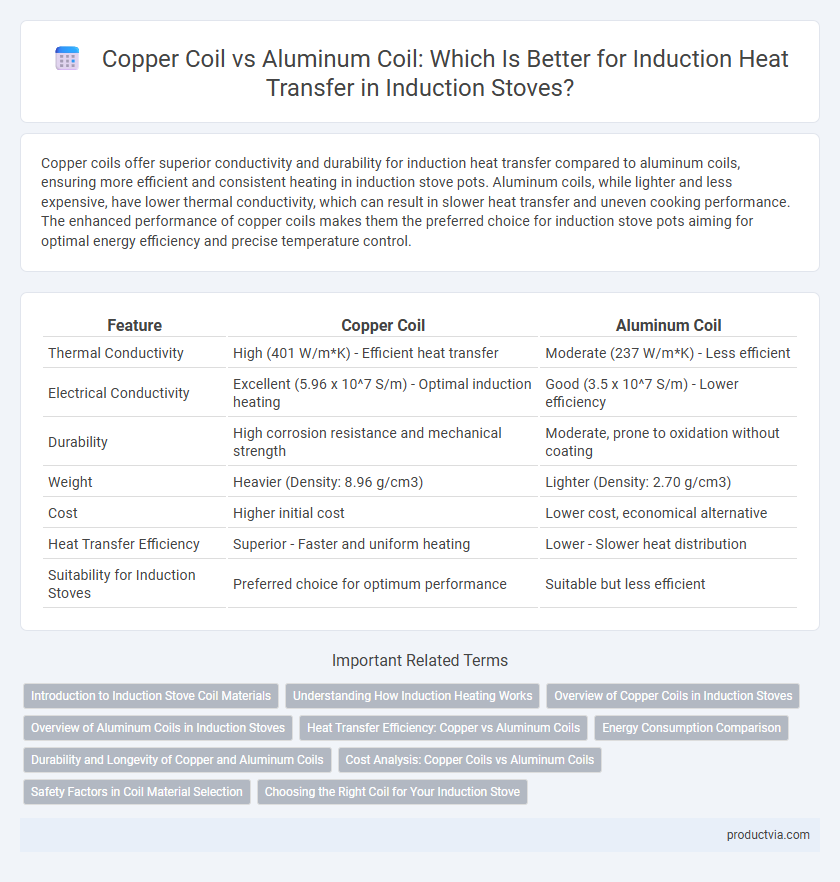

| Feature | Copper Coil | Aluminum Coil |

|---|---|---|

| Thermal Conductivity | High (401 W/m*K) - Efficient heat transfer | Moderate (237 W/m*K) - Less efficient |

| Electrical Conductivity | Excellent (5.96 x 10^7 S/m) - Optimal induction heating | Good (3.5 x 10^7 S/m) - Lower efficiency |

| Durability | High corrosion resistance and mechanical strength | Moderate, prone to oxidation without coating |

| Weight | Heavier (Density: 8.96 g/cm3) | Lighter (Density: 2.70 g/cm3) |

| Cost | Higher initial cost | Lower cost, economical alternative |

| Heat Transfer Efficiency | Superior - Faster and uniform heating | Lower - Slower heat distribution |

| Suitability for Induction Stoves | Preferred choice for optimum performance | Suitable but less efficient |

Introduction to Induction Stove Coil Materials

Copper coils exhibit superior electrical conductivity, enhancing energy efficiency and rapid heat transfer in induction stoves. Aluminum coils, while more cost-effective and lightweight, have lower conductivity, resulting in slower heating and reduced performance. The choice of coil material significantly impacts the stove's thermal response, durability, and overall efficiency.

Understanding How Induction Heating Works

Copper coils provide superior electrical conductivity compared to aluminum coils, resulting in more efficient electromagnetic induction and faster heat transfer in induction stoves. The higher conductivity of copper reduces energy loss, enabling the coil to generate stronger eddy currents in the cookware, which converts electrical energy into heat more effectively. Aluminum coils, while lighter and less expensive, suffer from higher resistance and lower heat transfer efficiency, making them less ideal for optimal induction heating performance.

Overview of Copper Coils in Induction Stoves

Copper coils in induction stoves provide superior electrical conductivity, enabling more efficient heat transfer and faster cooking times compared to aluminum coils. Their high thermal conductivity ensures consistent and even heating, reducing energy waste and improving overall stove performance. Copper's durability and resistance to oxidation contribute to a longer lifespan, making it the preferred choice for induction heating applications.

Overview of Aluminum Coils in Induction Stoves

Aluminum coils in induction stoves offer excellent thermal conductivity, enabling rapid and uniform heat distribution across the cooking surface. Their lightweight nature enhances energy efficiency and improves the overall durability of the stove by reducing mechanical stress. Although aluminum has a lower magnetic permeability than copper, advanced coil designs compensate for this, making aluminum coils a cost-effective and reliable option for induction heat transfer.

Heat Transfer Efficiency: Copper vs Aluminum Coils

Copper coils offer superior heat transfer efficiency in induction stoves due to their high thermal conductivity of approximately 401 W/m*K, which greatly enhances rapid and uniform heating. Aluminum coils, with a lower thermal conductivity around 237 W/m*K, result in slower heat transfer and less consistent temperature distribution. The higher electrical conductivity of copper also reduces energy loss, making copper coils the preferred choice for optimal induction heat transfer performance.

Energy Consumption Comparison

Copper coils exhibit higher electrical conductivity than aluminum coils, leading to more efficient induction heat transfer with reduced energy consumption. The superior thermal conductivity of copper minimizes energy loss during heating, resulting in faster heat-up times and lower power usage. Aluminum coils, while lighter and less costly, require more energy to achieve the same heating performance, increasing overall energy consumption in induction stoves.

Durability and Longevity of Copper and Aluminum Coils

Copper coils exhibit superior durability and longevity in induction stove heat transfer applications due to their higher resistance to corrosion and fatigue compared to aluminum coils. Aluminum coils, while lighter and more cost-effective, tend to degrade faster under thermal cycling, reducing their operational lifespan. The enhanced thermal conductivity and mechanical robustness of copper ensure sustained performance and extended service life in induction heating systems.

Cost Analysis: Copper Coils vs Aluminum Coils

Copper coils, known for superior thermal conductivity, typically cost significantly more than aluminum coils, impacting the overall production expense of induction stoves. Aluminum coils offer a more cost-effective alternative due to lower raw material and manufacturing costs, although they may sacrifice some efficiency in heat transfer. The choice between copper and aluminum coils hinges on balancing initial investment with long-term performance and energy savings in induction heating applications.

Safety Factors in Coil Material Selection

Copper coils in induction stoves offer superior safety due to their high electrical conductivity and resistance to overheating, minimizing the risk of coil failure or fire hazards. Aluminum coils, while more cost-effective, have lower thermal stability and are more prone to oxidation, which can compromise mechanical integrity and increase safety risks over time. Selecting copper coils ensures enhanced durability and safer operation, crucial for reliable induction heat transfer performance.

Choosing the Right Coil for Your Induction Stove

Copper coils offer superior electrical conductivity and heat transfer efficiency compared to aluminum coils, making them ideal for induction stove applications where rapid and even heating is crucial. Aluminum coils are lighter and less expensive but provide lower thermal conductivity, which can lead to slower response times and uneven heat distribution. Selecting copper coils enhances the overall performance and durability of the induction stove, ensuring consistent cooking results and energy efficiency.

Copper coil vs Aluminum coil for induction heat transfer Infographic

productvia.com

productvia.com