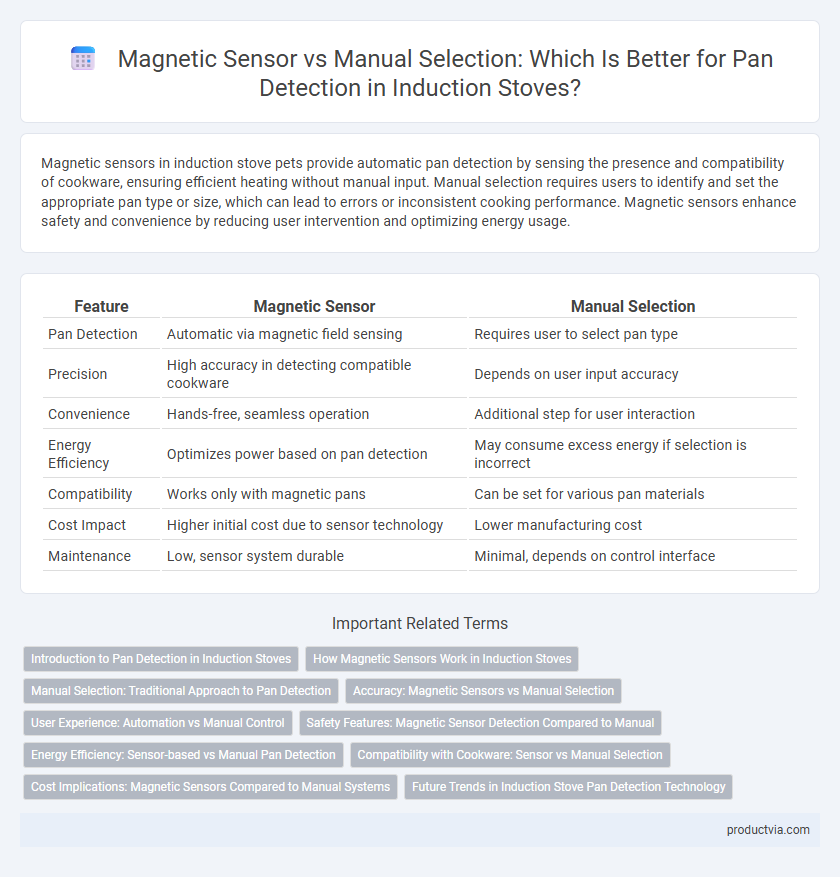

Magnetic sensors in induction stove pets provide automatic pan detection by sensing the presence and compatibility of cookware, ensuring efficient heating without manual input. Manual selection requires users to identify and set the appropriate pan type or size, which can lead to errors or inconsistent cooking performance. Magnetic sensors enhance safety and convenience by reducing user intervention and optimizing energy usage.

Table of Comparison

| Feature | Magnetic Sensor | Manual Selection |

|---|---|---|

| Pan Detection | Automatic via magnetic field sensing | Requires user to select pan type |

| Precision | High accuracy in detecting compatible cookware | Depends on user input accuracy |

| Convenience | Hands-free, seamless operation | Additional step for user interaction |

| Energy Efficiency | Optimizes power based on pan detection | May consume excess energy if selection is incorrect |

| Compatibility | Works only with magnetic pans | Can be set for various pan materials |

| Cost Impact | Higher initial cost due to sensor technology | Lower manufacturing cost |

| Maintenance | Low, sensor system durable | Minimal, depends on control interface |

Introduction to Pan Detection in Induction Stoves

Induction stoves use pan detection technology to ensure safe and efficient cooking by identifying compatible cookware on the cooking zone. Magnetic sensors detect the presence of ferromagnetic materials by measuring changes in electromagnetic fields, enabling automatic activation of the heating element only when suitable pans are placed. Manual selection requires users to specify the pan type or size, which may lead to errors or inefficiencies compared to the precise and automatic response of magnetic sensor-based detection systems.

How Magnetic Sensors Work in Induction Stoves

Magnetic sensors in induction stoves detect cookware by sensing changes in the magnetic field generated by the induction coil beneath the cooktop. When a pan with ferromagnetic material is placed on the stove, the magnetic sensor identifies the presence and size of the cookware, enabling automatic heating activation and precise temperature control. This technology enhances energy efficiency and safety by ensuring the stove only heats when compatible pans are detected, unlike manual selection which relies on user input rather than real-time detection.

Manual Selection: Traditional Approach to Pan Detection

Manual selection in induction stoves relies on users to choose the appropriate heating zone or power level based on pan placement, often requiring precise alignment and specific cookware types for optimal performance. This traditional approach lacks automatic adaptation, which can lead to inconsistent heat distribution and increased energy consumption. Despite its simplicity, manual selection can result in user errors and reduced cooking efficiency compared to modern magnetic sensor technology that detects pan presence and size automatically.

Accuracy: Magnetic Sensors vs Manual Selection

Magnetic sensors in induction stoves offer higher accuracy in pan detection by automatically recognizing compatible cookware based on its magnetic properties, reducing errors and energy waste. Manual selection relies on user input, which can lead to incorrect settings and inefficient heating if the pan type or size is misjudged. Magnetic sensors minimize human error and ensure optimal power adjustment, enhancing overall cooking performance and safety.

User Experience: Automation vs Manual Control

Magnetic sensor-based pan detection in induction stoves offers seamless automation by instantly recognizing compatible cookware, enhancing user convenience through effortless operation. Manual selection requires users to actively choose the pan type or size, which can lead to greater control but may complicate the cooking process and increase the risk of errors. Automated magnetic sensors reduce guesswork and optimize heating efficiency, significantly improving the overall user experience compared to manual control methods.

Safety Features: Magnetic Sensor Detection Compared to Manual

Magnetic sensor detection in induction stoves provides enhanced safety by automatically identifying compatible cookware, preventing the stove from heating when no suitable pan is present. This technology reduces risks of accidental burns or fires by ensuring activation only with proper magnetic cookware, unlike manual selection methods that rely on user input and can lead to human error. As a result, magnetic sensors offer more reliable pan detection, improving kitchen safety and energy efficiency.

Energy Efficiency: Sensor-based vs Manual Pan Detection

Magnetic sensor technology in induction stoves automatically detects compatible cookware, optimizing energy transfer and reducing wastage, whereas manual pan selection relies on user input, increasing the risk of inefficiency. Sensor-based detection ensures the stove only activates when a proper pan is in place, minimizing unnecessary power consumption. This intelligent automation significantly enhances overall energy efficiency compared to manual methods.

Compatibility with Cookware: Sensor vs Manual Selection

Magnetic sensors in induction stoves offer precise cookware compatibility by detecting ferromagnetic materials, ensuring efficient heating only with suitable pans such as cast iron or stainless steel. Manual selection relies on user input to choose cookware type, which may lead to less accurate detection and potential energy inefficiency if incorrect settings are chosen. The sensor-based system enhances safety and cooking performance by automatically adjusting to compatible cookware, minimizing user error and optimizing energy use.

Cost Implications: Magnetic Sensors Compared to Manual Systems

Magnetic sensors in induction stoves provide precise pan detection by automatically identifying compatible cookware, leading to higher manufacturing costs due to sophisticated sensor components. Manual selection systems rely on user input to detect pan presence, reducing hardware expenses but increasing the risk of user error and energy inefficiency. Cost implications favor manual systems for budget models, while magnetic sensors justify their expense through improved performance and user convenience in premium appliances.

Future Trends in Induction Stove Pan Detection Technology

Magnetic sensor technology in induction stoves enables precise pan detection by measuring the pan's magnetic properties, ensuring efficient energy transfer and safety. Manual selection methods require user input to identify pan type, which can lead to inaccuracies and reduced cooking performance. Future trends prioritize integrating advanced magnetic sensors with AI algorithms for automatic, real-time pan recognition, enhancing user convenience and optimizing cooking efficiency.

Magnetic sensor vs Manual selection for pan detection Infographic

productvia.com

productvia.com