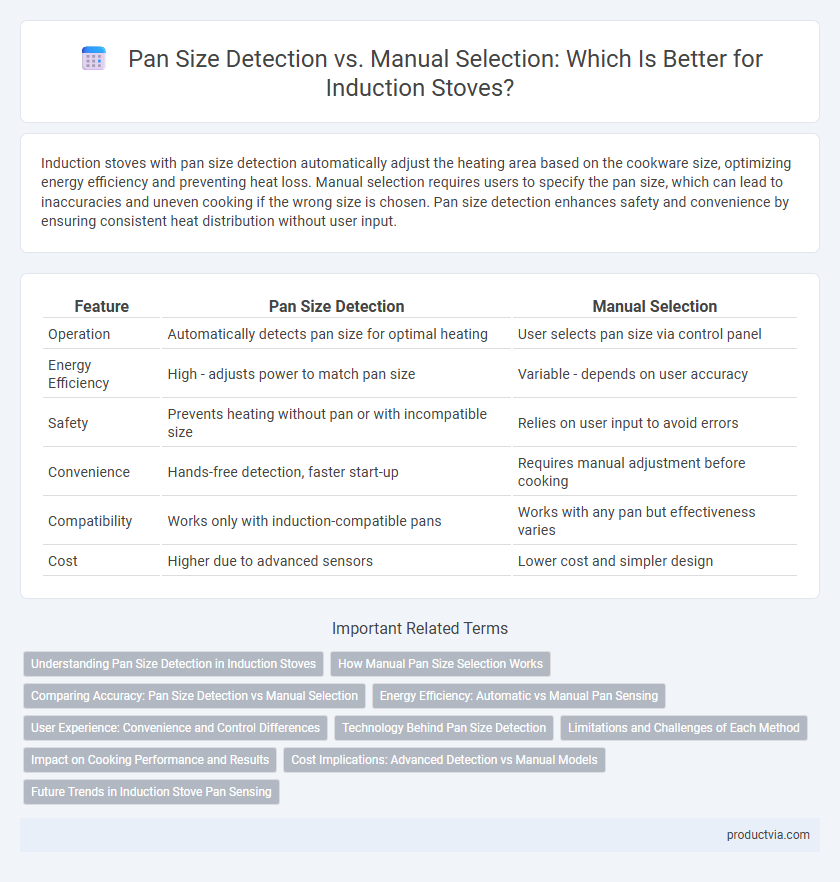

Induction stoves with pan size detection automatically adjust the heating area based on the cookware size, optimizing energy efficiency and preventing heat loss. Manual selection requires users to specify the pan size, which can lead to inaccuracies and uneven cooking if the wrong size is chosen. Pan size detection enhances safety and convenience by ensuring consistent heat distribution without user input.

Table of Comparison

| Feature | Pan Size Detection | Manual Selection |

|---|---|---|

| Operation | Automatically detects pan size for optimal heating | User selects pan size via control panel |

| Energy Efficiency | High - adjusts power to match pan size | Variable - depends on user accuracy |

| Safety | Prevents heating without pan or with incompatible size | Relies on user input to avoid errors |

| Convenience | Hands-free detection, faster start-up | Requires manual adjustment before cooking |

| Compatibility | Works only with induction-compatible pans | Works with any pan but effectiveness varies |

| Cost | Higher due to advanced sensors | Lower cost and simpler design |

Understanding Pan Size Detection in Induction Stoves

Pan size detection in induction stoves uses electromagnetic sensors to automatically identify the diameter of the cookware placed on the surface, optimizing heat distribution and energy efficiency. This technology contrasts with manual selection methods, where users must input pan size settings, risking improper heat application or increased energy consumption. Accurate pan size detection enhances cooking precision, safety, and overall stove performance by ensuring the induction coil activates only under the cookware area.

How Manual Pan Size Selection Works

Manual pan size selection on an induction stove involves the user specifying the cookware diameter through the stove's control panel, allowing the induction coil to adjust its magnetic field accordingly. This process ensures the heating zone matches the pan size, optimizing energy efficiency and preventing overheating of exposed cooktop areas. Unlike automatic pan size detection, manual selection offers precise control but requires user input for accurate temperature management and safety.

Comparing Accuracy: Pan Size Detection vs Manual Selection

Pan size detection in induction stoves offers superior accuracy by automatically adjusting the heating zone to match the pan's dimensions, ensuring energy efficiency and optimal cooking performance. Manual selection relies on user input, which can lead to mismatches between the pan size and heating element, causing uneven heating or energy waste. Advanced pan size detection technology reduces user error and enhances precision by detecting the exact pan diameter in real-time, providing consistent temperature control.

Energy Efficiency: Automatic vs Manual Pan Sensing

Automatic pan size detection in induction stoves optimizes energy efficiency by adjusting the heat output precisely to the cookware's dimensions, minimizing energy wastage. Manual selection often leads to mismatches between pan size and heating zone, causing unnecessary power consumption and uneven cooking. Advanced automatic sensors enable smarter energy usage, reducing electricity bills and promoting sustainable kitchen practices.

User Experience: Convenience and Control Differences

Pan size detection on induction stoves offers enhanced convenience by automatically adjusting power settings to match the cookware, reducing the need for manual input and minimizing guesswork. Manual selection provides users with greater control over temperature and cooking precision, allowing customization based on specific culinary needs or preferences. The balance between automatic adjustment and manual control impacts overall user experience, where ease of use competes with tailored cooking performance.

Technology Behind Pan Size Detection

Pan size detection technology in induction stoves utilizes magnetic sensor arrays and coil modulation techniques to identify the cookware's diameter precisely. This system adjusts the heating zone automatically, optimizing energy consumption and ensuring uniform heat distribution across the pan surface. Manual selection lacks this precision, often leading to inefficient energy use and uneven cooking performance.

Limitations and Challenges of Each Method

Pan size detection in induction stoves offers automatic adjustment of heating zones but faces limitations such as inaccurate detection with irregular or small cookware, leading to uneven heating and energy waste. Manual selection allows precise control over the cooking zone but introduces challenges including user error and the need for constant adjustments, which can decrease efficiency and safety. Both methods struggle with compatibility issues across diverse pan materials and shapes, impacting performance and user experience.

Impact on Cooking Performance and Results

Pan size detection technology on induction stoves automates power adjustment based on the detected cookware diameter, improving energy efficiency and preventing heat loss. Manual selection requires user input for pan size, which can lead to mismatched power settings, causing uneven cooking and longer heating times. Accurate pan size detection ensures precise temperature control, enhancing cooking performance and consistent results.

Cost Implications: Advanced Detection vs Manual Models

Pan size detection technology in induction stoves generally increases the appliance's cost due to the incorporation of sensors and advanced control systems. Manual selection models tend to be more affordable but may lead to inefficiencies such as uneven heating or energy waste when incorrect pan sizes are used. Investing in advanced detection systems can result in long-term savings through optimized energy consumption and enhanced cooking performance despite higher initial costs.

Future Trends in Induction Stove Pan Sensing

Future trends in induction stove pan sensing emphasize advanced pan size detection technologies that use precise magnetic field sensors and AI algorithms to automatically identify cookware dimensions. This enhances energy efficiency by optimizing heat distribution and minimizing power waste compared to manual selection methods. Integration of smart connectivity allows real-time feedback and adaptive cooking processes, marking a shift towards fully automated induction stove interfaces.

Pan size detection vs manual selection for induction stove Infographic

productvia.com

productvia.com