Pulp ejection juicers significantly simplify cleanup by automatically expelling pulp into a separate container, reducing manual handling and minimizing mess. Non-ejection juicers require frequent stops to empty the pulp container, increasing cleanup time and effort. Choosing a pulp ejection juicer enhances convenience and speeds up the juicing process with less post-use maintenance.

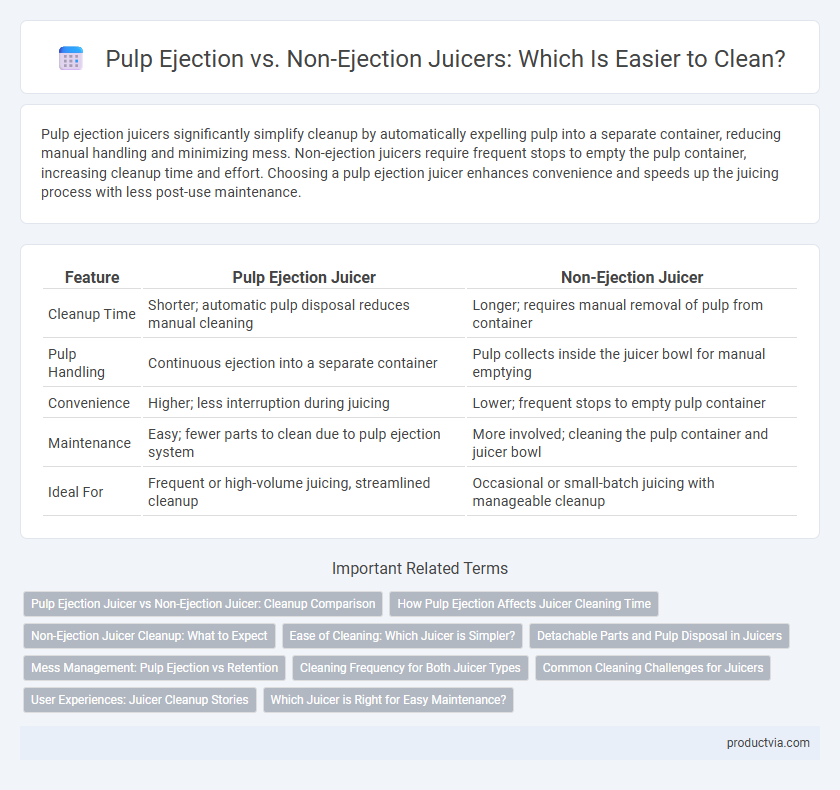

Table of Comparison

| Feature | Pulp Ejection Juicer | Non-Ejection Juicer |

|---|---|---|

| Cleanup Time | Shorter; automatic pulp disposal reduces manual cleaning | Longer; requires manual removal of pulp from container |

| Pulp Handling | Continuous ejection into a separate container | Pulp collects inside the juicer bowl for manual emptying |

| Convenience | Higher; less interruption during juicing | Lower; frequent stops to empty pulp container |

| Maintenance | Easy; fewer parts to clean due to pulp ejection system | More involved; cleaning the pulp container and juicer bowl |

| Ideal For | Frequent or high-volume juicing, streamlined cleanup | Occasional or small-batch juicing with manageable cleanup |

Pulp Ejection Juicer vs Non-Ejection Juicer: Cleanup Comparison

Pulp ejection juicers automatically expel pulp into a separate container, significantly reducing cleanup time by preventing pulp buildup inside the machine. Non-ejection juicers require manual removal of pulp from the juicer's chamber, which can result in more frequent disassembly and cleaning. The efficiency of pulp ejection juicers in managing residue leads to a more convenient and less labor-intensive cleanup process.

How Pulp Ejection Affects Juicer Cleaning Time

Juicers with pulp ejection systems significantly reduce cleaning time by automatically expelling pulp into a separate container, preventing buildup inside the machine. In contrast, non-ejection juicers require manual removal of pulp from the juicing chamber, resulting in longer and more tedious cleanup. The efficient separation of pulp in ejection models minimizes mess and allows for quicker disassembly and rinsing.

Non-Ejection Juicer Cleanup: What to Expect

Non-ejection juicers typically require manual removal of pulp, leading to a more involved cleanup process with rinsing and scrubbing pulp chambers and filters. Expect to spend additional time cleaning embedded fiber residues and small crevices compared to ejection models. Regular maintenance of non-ejection juicers ensures consistent performance and prevents buildup that may affect juice quality.

Ease of Cleaning: Which Juicer is Simpler?

Pulp ejection juicers simplify cleanup by automatically expelling pulp into an external container, reducing the need to disassemble multiple parts. Non-ejection juicers require manual removal of pulp from the juicing chamber, increasing cleaning time and effort. Choosing a pulp ejection juicer enhances ease of cleaning and maintains juicing efficiency.

Detachable Parts and Pulp Disposal in Juicers

Juicers with pulp ejection feature detachable pulp containers that simplify cleanup by allowing continuous juicing without frequent stops to remove pulp. Non-ejection juicers collect pulp inside the main chamber, requiring partial disassembly and manual removal of accumulated pulp for thorough cleaning. Detachable parts in ejection juicers reduce overall mess and streamline maintenance by enabling quick disposal of pulp and easy access to other components.

Mess Management: Pulp Ejection vs Retention

Pulp ejection juicers streamline mess management by automatically expelling pulp into a separate container, reducing cleanup time and preventing pulp buildup inside the machine. Non-ejection juicers retain pulp within the juicer, which can lead to more frequent disassembly and thorough cleaning to avoid residue accumulation. Choosing a pulp ejection model enhances efficiency in kitchen hygiene by minimizing direct contact with pulp waste and simplifying maintenance.

Cleaning Frequency for Both Juicer Types

Pulp ejection juicers require less frequent cleaning during continuous juicing sessions because they automatically expel pulp into a separate container, preventing buildup inside the machine. Non-ejection juicers necessitate more regular cleaning intervals as pulp accumulates inside the juicer chamber, increasing the chance of clogs and affecting juice quality. The reduced frequency of internal cleaning with pulp ejection juicers significantly enhances user convenience and maintains efficient juicing performance.

Common Cleaning Challenges for Juicers

Pulp ejection juicers simplify cleanup by automatically expelling pulp into a separate container, reducing manual handling and clogging issues commonly faced with non-ejection models. Non-ejection juicers require frequent stops to clear accumulated pulp from the filter, leading to longer cleaning times and increased frustration. Residual pulp buildup in non-ejection juicers often causes difficult-to-clean hard-to-reach crevices, complicating maintenance and hygiene.

User Experiences: Juicer Cleanup Stories

Users of pulp ejection juicers frequently highlight the convenience of continuous pulp discharge, which minimizes interruptions and simplifies cleanup by directing pulp into a separate container. In contrast, non-ejection juicer users often report needing to stop juicing intermittently to manually remove pulp, leading to a messier and more time-consuming cleanup process. User testimonials consistently reveal that pulp ejection juicers streamline post-juicing maintenance, making them preferred for efficiency and ease of cleaning.

Which Juicer is Right for Easy Maintenance?

Pulp ejection juicers expel the pulp into an external container, significantly reducing manual cleanup and allowing continuous juicing without frequent stops. Non-ejection juicers accumulate pulp inside the machine, requiring disassembly and more intensive cleaning after use. For easy maintenance, pulp ejection juicers offer superior convenience and time-saving benefits.

Pulp ejection juicer vs non-ejection juicer for cleanup Infographic

productvia.com

productvia.com