The separation spout in a juicer efficiently directs juice away from the pulp, minimizing clogging and ensuring a clearer liquid output. Direct pour models offer simplicity by allowing juice to flow straight into the container but may require frequent cleaning due to pulp accumulation. Choosing between these depends on the user's preference for ease of use versus continuous operation with minimal interruptions.

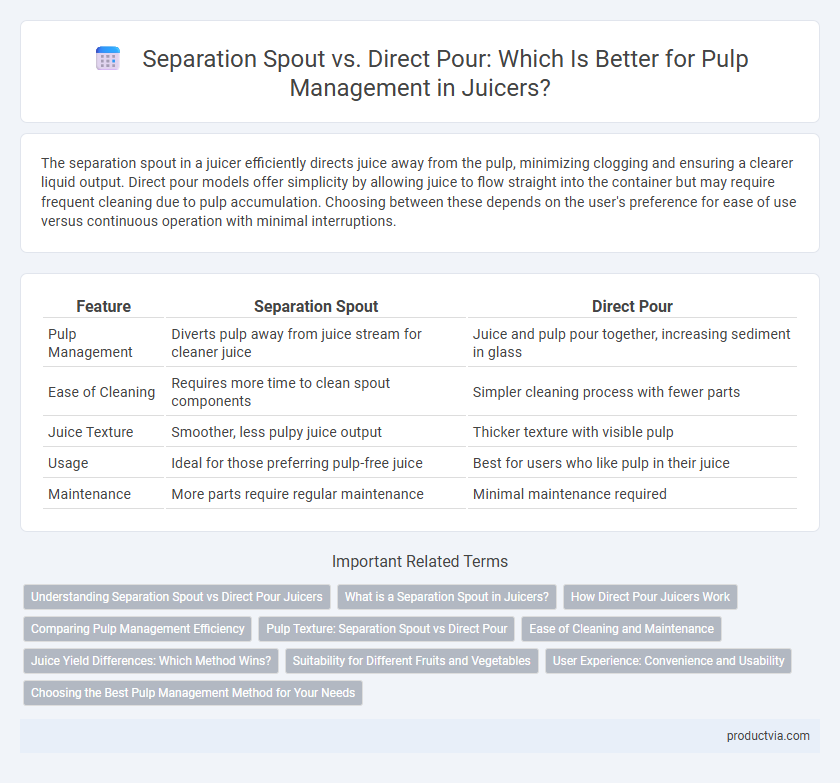

Table of Comparison

| Feature | Separation Spout | Direct Pour |

|---|---|---|

| Pulp Management | Diverts pulp away from juice stream for cleaner juice | Juice and pulp pour together, increasing sediment in glass |

| Ease of Cleaning | Requires more time to clean spout components | Simpler cleaning process with fewer parts |

| Juice Texture | Smoother, less pulpy juice output | Thicker texture with visible pulp |

| Usage | Ideal for those preferring pulp-free juice | Best for users who like pulp in their juice |

| Maintenance | More parts require regular maintenance | Minimal maintenance required |

Understanding Separation Spout vs Direct Pour Juicers

Separation spout juicers efficiently filter pulp by directing juice and pulp through distinct outlets, resulting in smoother juice with minimal residue. Direct pour juicers combine pulp and juice output, requiring additional filtration or manual straining to achieve pulp-free juice. Choosing between separation spout and direct pour models depends on the desired juice texture and pulp management preferences.

What is a Separation Spout in Juicers?

A separation spout in juicers is designed to efficiently direct juice away from the pulp, preventing clogging and ensuring smoother extraction. This spout helps manage pulp by channeling it separately into a designated container, enhancing the juicing experience and reducing cleanup time. Models with a separation spout optimize juice clarity and maintain consistent flow without mixing pulp back into the juice.

How Direct Pour Juicers Work

Direct pour juicers use an integrated pulp management system that continuously separates juice from the pulp during extraction, allowing the juice to flow directly into the container without the need for manual pulp removal. This design reduces clogging and streamlines the juicing process by automatically directing pulp to a designated container or chamber. The efficiency of direct pour juicers lies in their ability to maintain optimal juice flow rates and minimize cleanup efforts compared to traditional separation spout models.

Comparing Pulp Management Efficiency

Separation spouts enhance pulp management efficiency by directing juice and pulp into distinct containers, reducing pulp mixing and enabling easier cleanup compared to direct pour designs. Direct pour juicers tend to mix pulp with juice more frequently, which can create additional filtration needs and less precise pulp control. Optimizing pulp separation improves juice clarity and simplifies downstream processing or disposal.

Pulp Texture: Separation Spout vs Direct Pour

Separation spout juicers produce finer, drier pulp by efficiently extracting juice, resulting in a more fibrous texture ideal for composting or reusing in recipes. Direct pour juicers tend to yield wetter, coarser pulp with higher moisture content, making it less dry but richer in residual nutrients. Choosing between these methods affects pulp texture significantly, influencing both juice clarity and pulp usability.

Ease of Cleaning and Maintenance

The Separation Spout design simplifies cleaning by directing pulp away from the juice outlet, minimizing residue buildup and reducing maintenance frequency. Direct Pour models often require more thorough disassembly to clean both the pulp and juice pathways, increasing time and effort for maintenance. Choosing a juicer with a Separation Spout can enhance hygiene and prolong the appliance's lifespan through easier pulp management and efficient cleaning.

Juice Yield Differences: Which Method Wins?

Separation spout juicers typically achieve higher juice yield by efficiently filtering out pulp during extraction, minimizing juice loss and enhancing clarity. Direct pour models often sacrifice some juice quantity for simplicity, as pulp remains mixed and may reduce overall output. For maximizing juice yield, separation spout juicers provide superior performance by effectively managing pulp and ensuring more juice is collected from the same quantity of produce.

Suitability for Different Fruits and Vegetables

Separation spouts excel at managing fibrous and high-pulp fruits like oranges and carrots by funneling pulp away from the juice, resulting in smoother extraction. Direct pour systems suit softer fruits and leafy greens such as berries and spinach, minimizing clogging and preserving nutrient density. Selecting between these spout types depends on the texture and fiber content of the produce to optimize juice clarity and yield.

User Experience: Convenience and Usability

Separation spouts in juicers enhance user experience by neatly directing juice and pulp into different containers, reducing mess and simplifying cleanup. Direct pour systems provide convenience by allowing juice to flow straight into a glass, minimizing handling but often mixing pulp and juice. Users seeking efficient pulp management and easy cleaning typically prefer separation spout designs for better control and usability.

Choosing the Best Pulp Management Method for Your Needs

Separation spouts effectively direct pulp away from juice, reducing clogging and making cleanup easier, ideal for those who prefer clear juice and low maintenance. Direct pour systems allow pulp to mix with juice, enhancing fiber intake and providing a thicker texture, suitable for health-conscious users who prioritize nutritional content. Selecting the best pulp management method depends on whether you value juice clarity and convenience or prefer retaining pulp for added dietary fiber.

Separation Spout vs Direct Pour for Pulp Management Infographic

productvia.com

productvia.com