Pulp ejection juicers continuously expel pulp into a separate container, allowing for longer juicing sessions without frequent stops to clean out pulp buildup. Non-ejection juicers collect pulp inside a built-in chamber, requiring users to pause and empty the pulp to maintain performance. Choosing between pulp ejection and non-ejection models depends on convenience preferences and the volume of juicing planned.

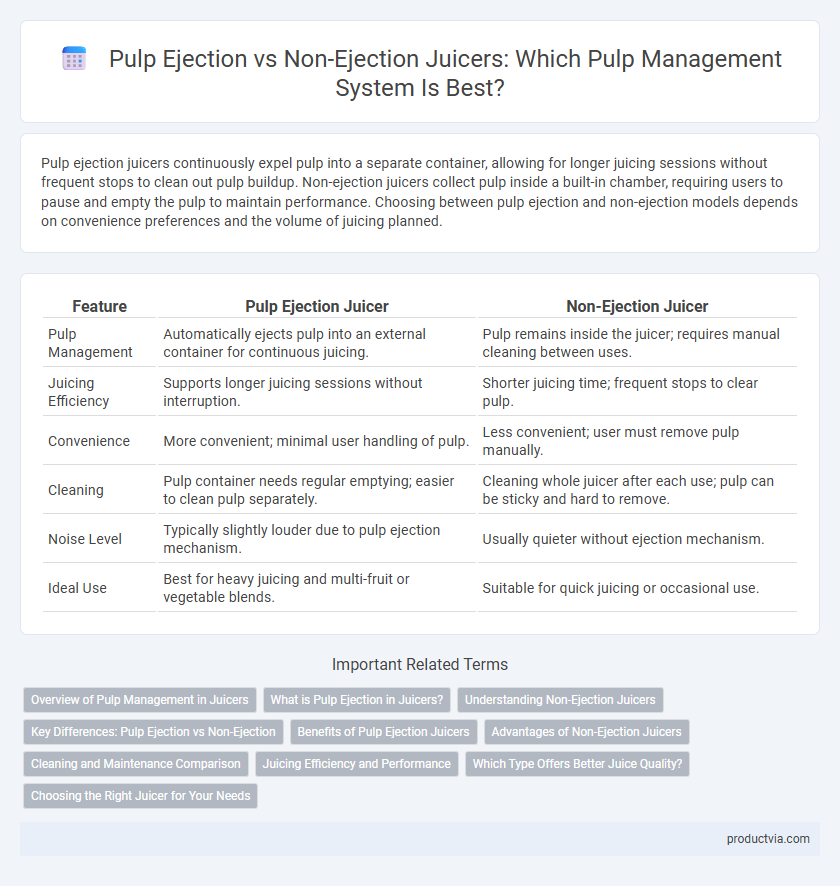

Table of Comparison

| Feature | Pulp Ejection Juicer | Non-Ejection Juicer |

|---|---|---|

| Pulp Management | Automatically ejects pulp into an external container for continuous juicing. | Pulp remains inside the juicer; requires manual cleaning between uses. |

| Juicing Efficiency | Supports longer juicing sessions without interruption. | Shorter juicing time; frequent stops to clear pulp. |

| Convenience | More convenient; minimal user handling of pulp. | Less convenient; user must remove pulp manually. |

| Cleaning | Pulp container needs regular emptying; easier to clean pulp separately. | Cleaning whole juicer after each use; pulp can be sticky and hard to remove. |

| Noise Level | Typically slightly louder due to pulp ejection mechanism. | Usually quieter without ejection mechanism. |

| Ideal Use | Best for heavy juicing and multi-fruit or vegetable blends. | Suitable for quick juicing or occasional use. |

Overview of Pulp Management in Juicers

Pulp ejection juicers continuously expel pulp into an external container, allowing for uninterrupted juicing and easier cleanup. Non-ejection juicers collect pulp internally, requiring frequent pauses to remove pulp manually, which may affect workflow efficiency. Effective pulp management depends on juicer type, with ejection systems optimizing juice yield and convenience for high-volume juicing.

What is Pulp Ejection in Juicers?

Pulp ejection in juicers refers to the mechanism that automatically expels pulp from the juicing chamber during operation, allowing continuous juicing without frequent stops to remove pulp manually. This feature efficiently separates juice from pulp, enhancing juice yield and convenience for the user. Juicers with pulp ejection systems typically handle large quantities of produce, making them ideal for high-volume juicing and maintaining consistent performance.

Understanding Non-Ejection Juicers

Non-ejection juicers retain pulp inside the juicing chamber, allowing users to control pulp consistency and reduce mess. These juicers often feature easy-to-clean designs and adjustable settings for customized juice texture. Choosing a non-ejection juicer benefits those seeking precision in pulp management and less frequent emptying during juicing sessions.

Key Differences: Pulp Ejection vs Non-Ejection

Pulp ejection juicers automatically expel the pulp into a separate container during juicing, allowing continuous operation without frequent stops for cleaning. Non-ejection juicers retain the pulp inside the juicer, requiring manual removal and cleaning after each use, which can interrupt the juicing process. The key difference lies in operational convenience and time efficiency, with pulp ejection models offering easier maintenance and uninterrupted juicing sessions.

Benefits of Pulp Ejection Juicers

Pulp ejection juicers efficiently expel pulp into a separate container, ensuring continuous, uninterrupted juicing and reducing the need for frequent cleaning. They enhance juice clarity and texture by preventing pulp buildup inside the juicer, resulting in smoother liquid output. This system supports longer juicing sessions, improving overall convenience and user experience.

Advantages of Non-Ejection Juicers

Non-ejection juicers excel in efficient pulp management by retaining the pulp inside the machine, allowing users to customize pulp consistency for various recipes and preferences. These models minimize mess and simplify cleanup, as the pulp collection bin captures all residue without requiring continuous disposal. Enhanced juice yield and nutrient retention are often observed due to the extended contact time between the juice and the pulp within non-ejection systems.

Cleaning and Maintenance Comparison

Pulp ejection juicers continuously expel pulp into an external container, reducing the need for frequent stops and easing the cleaning process by containing pulp separately from the main juicing components. Non-ejection juicers accumulate pulp inside the machine, requiring more frequent disassembly and cleaning of internal parts to prevent clogging and maintain optimal performance. Overall, pulp ejection models offer more convenience and less maintenance effort, making them preferable for users prioritizing easy cleaning.

Juicing Efficiency and Performance

Pulp ejection juicers expel pulp continuously, preventing clogging and allowing for longer juicing sessions with consistent performance and higher juice yield. Non-ejection juicers collect pulp internally, requiring frequent stops to empty the pulp container, which can reduce juicing efficiency and slow down the process. Choosing a juicer with pulp ejection enhances overall juicing efficiency and maintains steady performance, especially when processing large quantities of fruits and vegetables.

Which Type Offers Better Juice Quality?

Pulp ejection juicers continuously expel pulp during operation, preventing buildup and allowing for smoother, more efficient extraction that often results in clearer, higher-quality juice. Non-ejection juicers accumulate pulp internally, which can lead to slower juicing processes and potential mixing of juice with pulp, sometimes affecting clarity and texture. For optimal juice quality with minimal pulp contamination, pulp ejection models generally offer superior performance.

Choosing the Right Juicer for Your Needs

Pulp ejection juicers automatically separate and expel pulp during the juicing process, ideal for users seeking continuous juicing without frequent stops for cleaning. Non-ejection juicers retain pulp inside the juicer, offering better control over pulp consistency but requiring manual removal, suitable for those who prefer customizing juice texture. Selecting the right juicer depends on your preference for convenience versus control in pulp management and the amount of maintenance you are willing to perform.

Pulp ejection vs Non-ejection for pulp management Infographic

productvia.com

productvia.com