Pulp ejection juicers automatically expel pulp into a separate container, simplifying waste management by allowing continuous juicing without frequent stops. Non-ejection juicers collect pulp inside the machine, requiring manual removal and cleaning after each session, which can be less convenient. Choosing between these options depends on user preference for ease of use and clean-up efficiency.

Table of Comparison

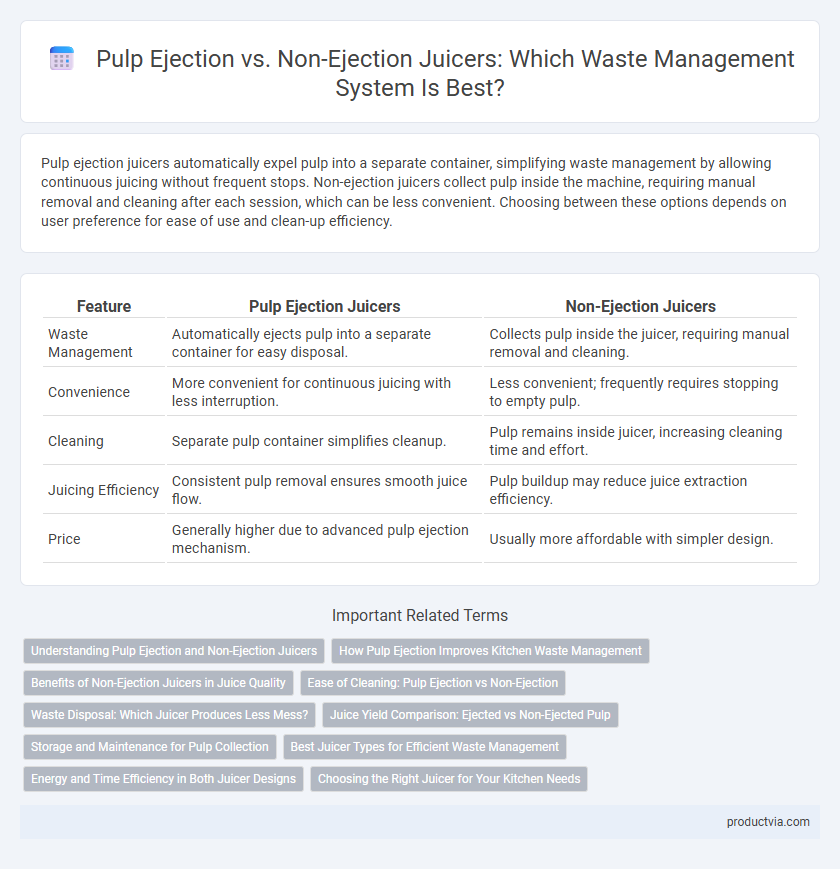

| Feature | Pulp Ejection Juicers | Non-Ejection Juicers |

|---|---|---|

| Waste Management | Automatically ejects pulp into a separate container for easy disposal. | Collects pulp inside the juicer, requiring manual removal and cleaning. |

| Convenience | More convenient for continuous juicing with less interruption. | Less convenient; frequently requires stopping to empty pulp. |

| Cleaning | Separate pulp container simplifies cleanup. | Pulp remains inside juicer, increasing cleaning time and effort. |

| Juicing Efficiency | Consistent pulp removal ensures smooth juice flow. | Pulp buildup may reduce juice extraction efficiency. |

| Price | Generally higher due to advanced pulp ejection mechanism. | Usually more affordable with simpler design. |

Understanding Pulp Ejection and Non-Ejection Juicers

Pulp ejection juicers automatically expel pulp into a separate container, allowing for continuous juicing without frequent stops to empty waste. Non-ejection juicers collect pulp inside the juicer, requiring users to manually remove the pulp and clean the device more often. Choosing between them depends on convenience needs and waste management preferences, with pulp ejection models offering ease in handling pulp disposal.

How Pulp Ejection Improves Kitchen Waste Management

Pulp ejection juicers automatically expel the pulp into a separate container, significantly reducing kitchen waste buildup during juicing. This feature streamlines cleanup by isolating fiber waste, making it easier to compost or dispose of without mixing with juice or other kitchen residues. Efficient pulp management minimizes odor and clutter, improving overall hygiene and waste handling in the kitchen.

Benefits of Non-Ejection Juicers in Juice Quality

Non-ejection juicers retain pulp within the juicing chamber, allowing for better control over juice consistency and maximizing nutrient preservation. By minimizing oxidation and reducing exposure to air, these juicers enhance the flavor intensity and shelf life of the juice. This method ensures a smoother texture and higher retention of natural enzymes and vitamins compared to pulp ejection models.

Ease of Cleaning: Pulp Ejection vs Non-Ejection

Pulp ejection juicers automatically expel pulp into an external container, significantly simplifying the cleaning process by preventing pulp buildup inside the juicer. Non-ejection juicers require manual removal of accumulated pulp, making cleaning more time-consuming and potentially messier. Choosing a pulp ejection model enhances waste management efficiency and reduces effort in maintaining juicer hygiene.

Waste Disposal: Which Juicer Produces Less Mess?

Pulp ejection juicers automatically expel pulp into a separate container, minimizing cleanup and reducing waste buildup inside the juicer. Non-ejection juicers require manual removal of pulp, often leading to more mess and longer cleaning times. For efficient waste disposal and less countertop mess, pulp ejection models are the preferred choice.

Juice Yield Comparison: Ejected vs Non-Ejected Pulp

Juicers with pulp ejection systems often provide higher juice yield by continuously expelling pulp, preventing clogging and allowing more efficient extraction of liquid from fruits and vegetables. Non-ejection juicers retain pulp inside, which can limit juice output as accumulated pulp reduces the juicer's efficiency. Studies show that pulp ejection models can increase juice yield by up to 15% compared to non-ejection types, enhancing overall waste management and extraction performance.

Storage and Maintenance for Pulp Collection

Pulp ejection juicers automatically expel pulp into an external container, reducing the need for frequent emptying and simplifying waste management. Non-ejection juicers collect pulp inside the machine's internal chamber, requiring regular stops to manually remove accumulated pulp for optimal performance. Efficient pulp storage and maintenance impact overall juicer hygiene and convenience, with ejection models favoring continuous juicing and non-ejection designs necessitating periodic cleaning to prevent clogging.

Best Juicer Types for Efficient Waste Management

Pulp ejection juicers continuously expel pulp into an external container, enabling uninterrupted juicing and simpler waste disposal, making them ideal for high-volume juice preparation. Non-ejection juicers collect pulp inside an internal chamber, requiring periodic manual removal, which can slow the process and complicate waste management. Centrifugal and masticating juicers with external pulp ejection systems offer the best efficiency for seamless pulp separation and easier cleanup in both home and commercial settings.

Energy and Time Efficiency in Both Juicer Designs

Pulp ejection juicers enhance energy and time efficiency by automatically expelling pulp during operation, reducing the need for frequent pauses and manual cleanup. Non-ejection juicers conserve energy by processing pulp within the container but require additional time for stops and manual pulp removal, impacting overall juicing speed. Choosing pulp ejection models increases continuous juicing productivity, whereas non-ejection designs may minimize energy use per cycle but slow total juicing throughput.

Choosing the Right Juicer for Your Kitchen Needs

Pulp ejection juicers continuously expel pulp into an external container, making them ideal for users who prefer easy waste disposal and uninterrupted juicing sessions. Non-ejection juicers collect pulp internally, requiring manual removal but offering more compact designs suitable for smaller kitchens. Selecting between pulp ejection and non-ejection models depends on your juice frequency, kitchen space, and preference for convenience in waste management.

Pulp Ejection vs Non-Ejection for waste management Infographic

productvia.com

productvia.com