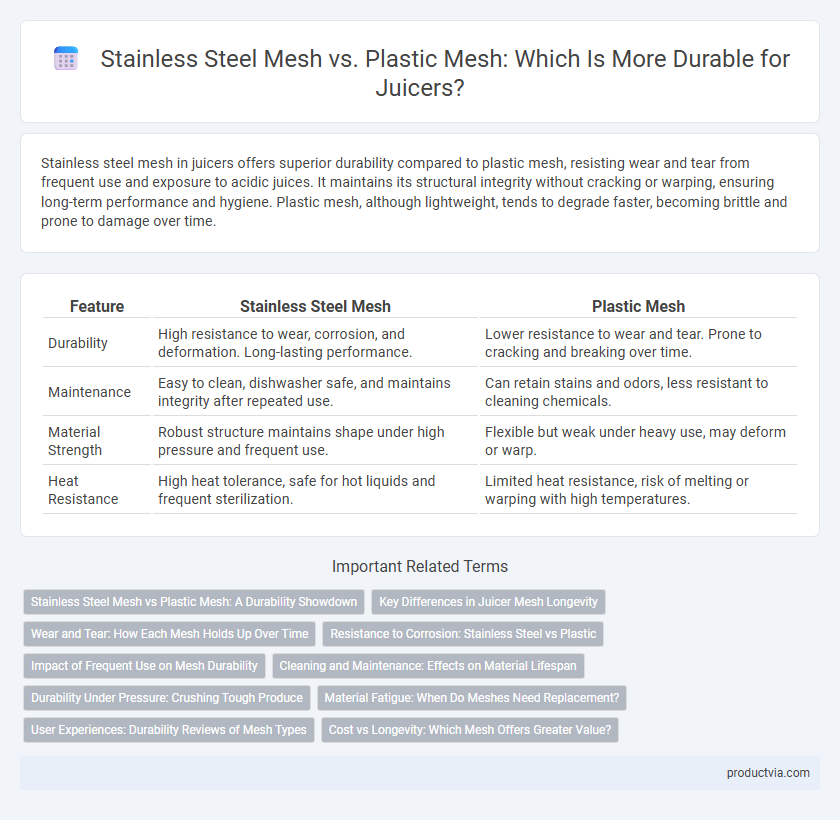

Stainless steel mesh in juicers offers superior durability compared to plastic mesh, resisting wear and tear from frequent use and exposure to acidic juices. It maintains its structural integrity without cracking or warping, ensuring long-term performance and hygiene. Plastic mesh, although lightweight, tends to degrade faster, becoming brittle and prone to damage over time.

Table of Comparison

| Feature | Stainless Steel Mesh | Plastic Mesh |

|---|---|---|

| Durability | High resistance to wear, corrosion, and deformation. Long-lasting performance. | Lower resistance to wear and tear. Prone to cracking and breaking over time. |

| Maintenance | Easy to clean, dishwasher safe, and maintains integrity after repeated use. | Can retain stains and odors, less resistant to cleaning chemicals. |

| Material Strength | Robust structure maintains shape under high pressure and frequent use. | Flexible but weak under heavy use, may deform or warp. |

| Heat Resistance | High heat tolerance, safe for hot liquids and frequent sterilization. | Limited heat resistance, risk of melting or warping with high temperatures. |

Stainless Steel Mesh vs Plastic Mesh: A Durability Showdown

Stainless steel mesh outperforms plastic mesh in juicer durability due to its resistance to corrosion, high temperatures, and wear over time. Plastic mesh tends to degrade, crack, or warp under prolonged exposure to moisture and pressure, compromising performance. Choosing stainless steel mesh guarantees longer-lasting juice extraction efficiency and consistent results.

Key Differences in Juicer Mesh Longevity

Stainless steel mesh in juicers offers superior durability due to its resistance to rust, corrosion, and physical wear, ensuring a longer lifespan compared to plastic mesh. Plastic mesh is prone to cracking, deforming, and discoloration over time, especially when exposed to frequent juicing and cleaning. The metal mesh also maintains consistent juicing performance, while plastic tends to degrade, impacting juice quality and requiring more frequent replacement.

Wear and Tear: How Each Mesh Holds Up Over Time

Stainless steel mesh outperforms plastic mesh in durability, offering superior resistance to wear and tear due to its robust material composition and ability to withstand repeated use without deformation. Over time, plastic mesh tends to degrade, crack, or warp from constant exposure to pressure and moisture, reducing juicer efficiency. Stainless steel retains its structural integrity and sharpness, ensuring consistent performance and longevity in juicing applications.

Resistance to Corrosion: Stainless Steel vs Plastic

Stainless steel mesh offers superior resistance to corrosion due to its metal alloys forming a protective oxide layer that prevents rust, making it ideal for juicer components exposed to moisture and acidic fruit juices. Plastic mesh resists corrosion inherently because it is non-metallic and immune to rust, but it can degrade or become brittle over time when exposed to acidic substances and high temperatures. The choice between stainless steel and plastic mesh affects the juicer's durability, with stainless steel providing longer-lasting performance under harsh conditions and plastic offering lightweight resistance without rust concerns.

Impact of Frequent Use on Mesh Durability

Stainless steel mesh exhibits superior durability compared to plastic mesh, especially under frequent use, due to its resistance to wear, heat, and corrosion. Plastic mesh tends to degrade faster, becoming brittle and prone to cracking or warping after repeated exposure to pressure and moisture. Juicers equipped with stainless steel meshes maintain consistent performance and require less frequent replacement, making them more cost-effective for long-term use.

Cleaning and Maintenance: Effects on Material Lifespan

Stainless steel mesh juicer filters offer superior durability and resistance to wear during cleaning compared to plastic mesh, which can degrade or crack over time with frequent washing. The non-porous surface of stainless steel prevents residue buildup, ensuring easier maintenance and extending the lifespan of the juicer component. Plastic mesh requires more careful handling to avoid scratches and deformation, which can reduce efficiency and shorten overall durability.

Durability Under Pressure: Crushing Tough Produce

Stainless steel mesh offers superior durability under pressure when crushing tough produce, resisting bending and breaking during high-torque juicing tasks. Plastic mesh tends to degrade faster, often warping or cracking over time with consistent heavy use. The robust and corrosion-resistant properties of stainless steel ensure long-lasting performance and maintain juicing efficiency.

Material Fatigue: When Do Meshes Need Replacement?

Stainless steel mesh in juicers exhibits superior durability compared to plastic mesh, resisting material fatigue under continuous exposure to acidic fruit juices and mechanical stress. Plastic meshes tend to wear out faster, showing cracks and deformation that compromise filtration efficiency, typically requiring replacement after 6 to 12 months of regular use. Stainless steel meshes can last several years without significant degradation, providing a more cost-effective and durable option for long-term juicing.

User Experiences: Durability Reviews of Mesh Types

Stainless steel mesh juicers receive high praise for their superior durability, resisting corrosion and maintaining sharpness over prolonged use, which leads to longer-lasting performance. Plastic mesh versions often face criticism for wear and tear, including cracking and clogging, which ultimately shortens their lifespan and requires frequent replacement. User reviews consistently highlight stainless steel mesh as the preferred choice for heavy juicing due to its robustness and ease of cleaning.

Cost vs Longevity: Which Mesh Offers Greater Value?

Stainless steel mesh juicer filters offer superior durability compared to plastic mesh, resisting wear, corrosion, and frequent use for years without degradation. Although stainless steel mesh comes with a higher upfront cost, its longevity reduces replacement frequency, making it more cost-effective over time. Plastic mesh may have a lower initial price but tends to wear out faster, leading to increased long-term expenses and less overall value.

Stainless steel mesh vs Plastic mesh for durability Infographic

productvia.com

productvia.com