Pulp ejector juicers automatically expel pulp during juicing, allowing for continuous operation and easier cleanup by preventing pulp buildup inside the machine. Non-ejector juicers retain the pulp internally, which requires manual removal and can interrupt juicing sessions but often results in more compact designs. Choosing between pulp ejector and non-ejector juicers depends on preferences for convenience and maintenance versus size and juicing style.

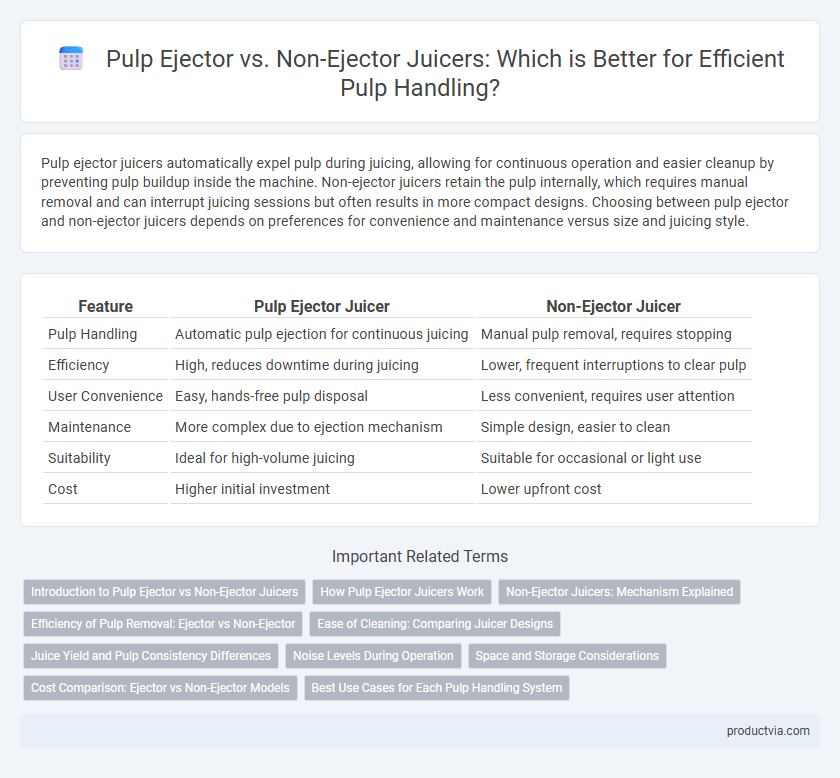

Table of Comparison

| Feature | Pulp Ejector Juicer | Non-Ejector Juicer |

|---|---|---|

| Pulp Handling | Automatic pulp ejection for continuous juicing | Manual pulp removal, requires stopping |

| Efficiency | High, reduces downtime during juicing | Lower, frequent interruptions to clear pulp |

| User Convenience | Easy, hands-free pulp disposal | Less convenient, requires user attention |

| Maintenance | More complex due to ejection mechanism | Simple design, easier to clean |

| Suitability | Ideal for high-volume juicing | Suitable for occasional or light use |

| Cost | Higher initial investment | Lower upfront cost |

Introduction to Pulp Ejector vs Non-Ejector Juicers

Pulp ejector juicers automatically discharge pulp through a separate outlet, ensuring continuous juicing without frequent stops to clear pulp buildup. Non-ejector juicers collect pulp internally, requiring manual removal which can interrupt juicing sessions and affect efficiency. Choosing between pulp ejector and non-ejector models depends on desired convenience, juicing speed, and ease of cleanup.

How Pulp Ejector Juicers Work

Pulp ejector juicers work by automatically expelling pulp through a dedicated outlet, allowing continuous juicing without frequent stops to clear pulp buildup. This mechanism enhances efficiency by maintaining consistent juice flow and preventing clogging, especially useful for juicing large quantities of fibrous fruits and vegetables. In contrast, non-ejector juicers require manual pulp removal, which interrupts juicing and can reduce overall productivity.

Non-Ejector Juicers: Mechanism Explained

Non-ejector juicers retain pulp inside the juicing chamber, allowing users to control pulp consistency and reduce mess during operation. Their mechanism involves continuous grinding and pressing of fruits and vegetables, with pulp compacted within the juicer rather than expelled, which can result in higher juice yield and smoother texture. Non-ejector juicers require periodic manual cleaning to remove accumulated pulp, balancing convenience with pulp retention benefits.

Efficiency of Pulp Removal: Ejector vs Non-Ejector

Pulp ejector juicers offer superior efficiency in pulp removal by automatically expelling the pulp during the juicing process, reducing buildup and allowing continuous operation with minimal interruptions. Non-ejector juicers require manual pulp removal, which can slow down juicing and increase cleanup time. The automatic pulp ejection feature enhances overall juicing speed and maintains consistent performance, making ejector models more efficient for high-volume juicing tasks.

Ease of Cleaning: Comparing Juicer Designs

Pulp ejector juicers offer superior ease of cleaning by automatically expelling pulp during operation, reducing manual removal and minimizing pulp buildup inside the machine. Non-ejector models require frequent disassembly to clear accumulated pulp, which can be more time-consuming and cumbersome. Choosing a pulp ejector design streamlines maintenance, enhances hygiene, and improves overall juicing efficiency.

Juice Yield and Pulp Consistency Differences

Pulp ejector juicers expel pulp separately, enhancing juice yield by preventing pulp buildup and enabling continuous extraction, whereas non-ejector juicers retain pulp within the chamber, potentially reducing efficiency due to clogging. The pulp consistency from ejector models tends to be drier and more compact, providing clearer juice with less residue, while non-ejector juicers produce wetter pulp, which can affect overall juice texture. Choosing between ejector and non-ejector designs impacts both the efficiency of juice extraction and the quality of the pulp byproduct.

Noise Levels During Operation

Pulp ejector juicers typically generate higher noise levels due to the mechanisms involved in expelling pulp continuously during operation. Non-ejector juicers operate more quietly as they collect pulp internally, reducing mechanical movement and vibration. Noise levels in pulp ejector models can exceed 80 decibels, whereas non-ejector models often stay below 65 decibels, making them preferable for quiet kitchen environments.

Space and Storage Considerations

Pulp ejector juicers automatically expel pulp into a separate container, reducing the need for frequent emptying and optimizing counter space. Non-ejector juicers collect pulp inside the main unit, requiring more storage space and regular manual disposal to maintain efficiency. Choosing a pulp ejector model enhances workspace organization and minimizes clutter by managing pulp handling more effectively.

Cost Comparison: Ejector vs Non-Ejector Models

Pulp ejector juicers typically have higher initial costs due to advanced mechanisms designed to automatically expel pulp, reducing manual cleaning time and improving efficiency. Non-ejector models are generally more affordable upfront but may incur higher maintenance expenses over time because pulp removal requires manual intervention, increasing labor costs. Evaluating total cost of ownership should consider both purchase price and long-term operational expenses to determine the most economical option for pulp handling needs.

Best Use Cases for Each Pulp Handling System

Pulp ejector juicers efficiently expel pulp directly into a separate container, making them ideal for users who prefer continuous juicing sessions without frequent stops for cleaning. Non-ejector juicers retain pulp inside the machine, better suited for those who want to use the pulp for recipes or composting, as it allows for easier monitoring and control over pulp consistency. Choosing between the two depends on whether immediate pulp disposal or pulp reuse is the primary priority in the juicing process.

Pulp ejector vs Non-ejector for pulp handling Infographic

productvia.com

productvia.com