Pyrolytic ovens use extremely high temperatures to burn off food residues, turning them into ash that can be easily wiped away, offering a thorough and hassle-free cleaning experience. Catalytic ovens feature special liners that absorb and break down grease and food splatters during regular cooking, requiring less energy but sometimes needing additional manual cleaning. Both methods provide self-cleaning convenience, with pyrolytic systems delivering more intensive cleaning and catalytic liners offering continuous maintenance.

Table of Comparison

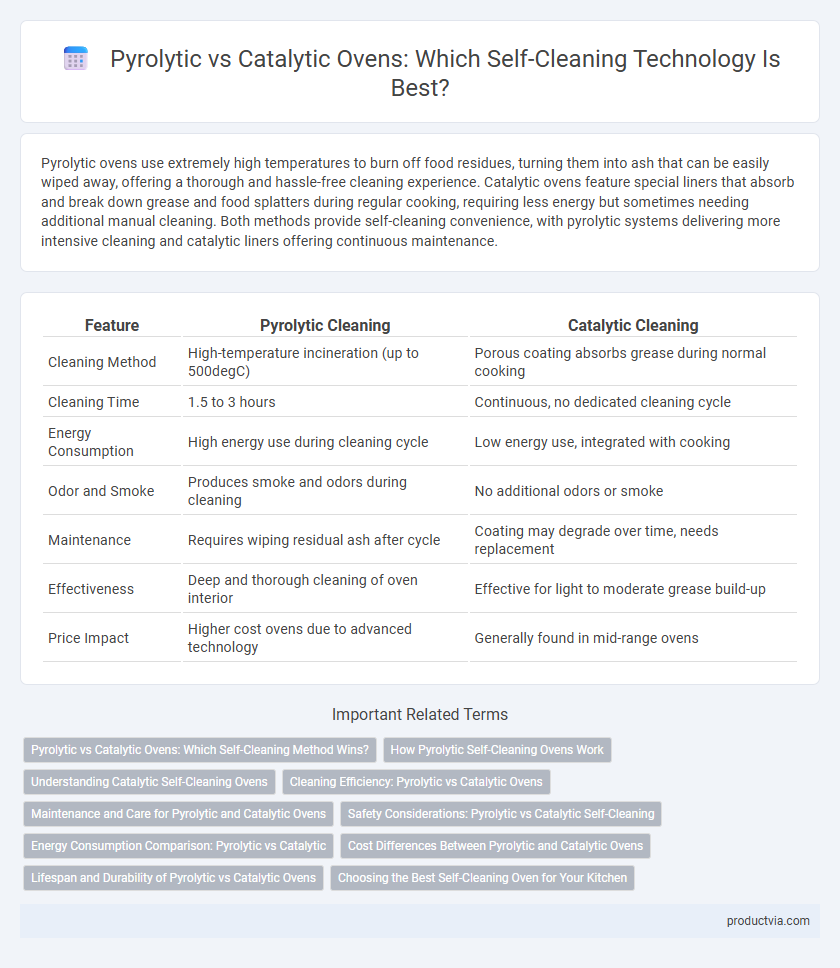

| Feature | Pyrolytic Cleaning | Catalytic Cleaning |

|---|---|---|

| Cleaning Method | High-temperature incineration (up to 500degC) | Porous coating absorbs grease during normal cooking |

| Cleaning Time | 1.5 to 3 hours | Continuous, no dedicated cleaning cycle |

| Energy Consumption | High energy use during cleaning cycle | Low energy use, integrated with cooking |

| Odor and Smoke | Produces smoke and odors during cleaning | No additional odors or smoke |

| Maintenance | Requires wiping residual ash after cycle | Coating may degrade over time, needs replacement |

| Effectiveness | Deep and thorough cleaning of oven interior | Effective for light to moderate grease build-up |

| Price Impact | Higher cost ovens due to advanced technology | Generally found in mid-range ovens |

Pyrolytic vs Catalytic Ovens: Which Self-Cleaning Method Wins?

Pyrolytic ovens use high temperatures around 500degC to turn food residues into ash, offering a thorough and hands-free cleaning process, while catalytic ovens feature special liners that absorb and break down grease at normal cooking temperatures, requiring less energy but more frequent maintenance. Pyrolytic systems are often preferred for their deep-clean capabilities and minimal user intervention, although they consume more power and need a cooldown period after cleaning. Catalytic ovens provide a more energy-efficient option with ongoing grease breakdown during cooking, but they may require liner replacement over time to maintain effectiveness.

How Pyrolytic Self-Cleaning Ovens Work

Pyrolytic self-cleaning ovens operate by heating the interior to extremely high temperatures, typically around 500degC (932degF), incinerating food residues and grease into ash that can be easily wiped away. This process involves a sealed oven cavity designed to withstand intense heat without damaging components or releasing fumes. Unlike catalytic ovens that use special liners to absorb grease, pyrolytic ovens offer a thorough cleaning cycle completed in about 1.5 to 3 hours, requiring no chemical cleaners.

Understanding Catalytic Self-Cleaning Ovens

Catalytic self-cleaning ovens use special liners coated with porous enamel that absorbs and breaks down grease and food residues at normal cooking temperatures, reducing the need for high-heat cleaning cycles. These liners continuously work during typical oven use, making maintenance less labor-intensive compared to pyrolytic ovens that require intense heating up to 500degC to incinerate grime. Catalytic ovens provide energy-efficient cleaning while preserving sensitive oven components by avoiding extreme heat exposure.

Cleaning Efficiency: Pyrolytic vs Catalytic Ovens

Pyrolytic ovens use extremely high temperatures around 500degC to incinerate food residues into ash, ensuring thorough cleaning with minimal manual effort. Catalytic ovens feature porous liners coated with a catalyst that breaks down grease and food splatters at regular cooking temperatures, offering continuous, moderate cleaning but less effective on heavy soiling. Pyrolytic cleaning provides superior efficiency for deep stains, while catalytic cleaning is better suited for maintaining cleanliness during everyday cooking.

Maintenance and Care for Pyrolytic and Catalytic Ovens

Pyrolytic ovens require a high-temperature cleaning cycle that burns off residues, leaving only ash that can be easily wiped away, reducing the need for manual scrubbing. Catalytic ovens use porous liners coated with a catalyst that absorbs and breaks down grease at normal cooking temperatures, but the liners must be replaced periodically to maintain effectiveness. Regular maintenance of pyrolytic ovens involves ensuring seals remain intact to withstand high heat, while catalytic ovens benefit from occasional manual cleaning of non-catalytic surfaces to complement the liners' function.

Safety Considerations: Pyrolytic vs Catalytic Self-Cleaning

Pyrolytic ovens reach temperatures up to 500degC, incinerating food residues safely with minimal user intervention but require the door to remain locked during the cleaning cycle to prevent burns. Catalytic ovens use porous liners coated with a catalyst to absorb and oxidize grease at lower temperatures, reducing the risk of high-heat hazards but needing regular maintenance to remain effective and avoid buildup. Both systems offer safety advantages; however, pyrolytic cleaning demands strict adherence to safety protocols due to extreme heat, while catalytic surfaces provide safer, continuous cleaning without the intense thermal risks.

Energy Consumption Comparison: Pyrolytic vs Catalytic

Pyrolytic ovens consume approximately 3.5 kWh per cleaning cycle by heating to around 500degC to burn off residues, whereas catalytic ovens use lower temperatures around 200degC with energy consumption closer to 1.5 kWh as the special liners absorb grease and food residues during regular cooking. Pyrolytic self-cleaning requires higher energy input due to intense heat and longer cycle durations, often between 1.5 to 3 hours, compared to catalytic cleaning which operates continuously and more efficiently without dedicated cleaning cycles. Choosing catalytic ovens can reduce overall energy costs over time, but pyrolytic models offer deeper cleaning at the expense of higher electricity consumption per cycle.

Cost Differences Between Pyrolytic and Catalytic Ovens

Pyrolytic ovens typically cost significantly more upfront compared to catalytic ovens due to their advanced heating elements and automated high-temperature cleaning cycles. Catalytic ovens, which use specialized liners to absorb and break down grease, offer a more affordable option but often require manual intervention to maintain efficiency. Over time, pyrolytic ovens may save money on maintenance and cleaning supplies, offsetting their initial higher investment.

Lifespan and Durability of Pyrolytic vs Catalytic Ovens

Pyrolytic ovens feature a high-temperature self-cleaning cycle that effectively incinerates food residues, enhancing overall durability and lifespan by preventing buildup and corrosion. Catalytic ovens rely on special liner panels that absorb and oxidize grease during regular cooking, but these panels degrade over time and require replacement, potentially reducing the oven's longevity. The robust construction and fewer maintenance demands of pyrolytic ovens generally result in a longer operational lifespan compared to catalytic models.

Choosing the Best Self-Cleaning Oven for Your Kitchen

Pyrolytic ovens use extremely high temperatures, around 900degF (482degC), to incinerate food residues into ash, requiring minimal manual effort for cleaning compared to catalytic ovens, which use special liners coated with a porous material to absorb and break down grease at lower temperatures. Pyrolytic models are ideal for heavy-duty, less frequent cleaning needs and tend to be more energy-intensive, while catalytic ovens offer continuous cleaning during regular cooking cycles but may require manual intervention for tougher residues. Selecting the best self-cleaning oven depends on your cooking habits, kitchen energy efficiency preferences, and the ease of maintenance you desire.

Pyrolytic vs Catalytic for self-cleaning Infographic

productvia.com

productvia.com