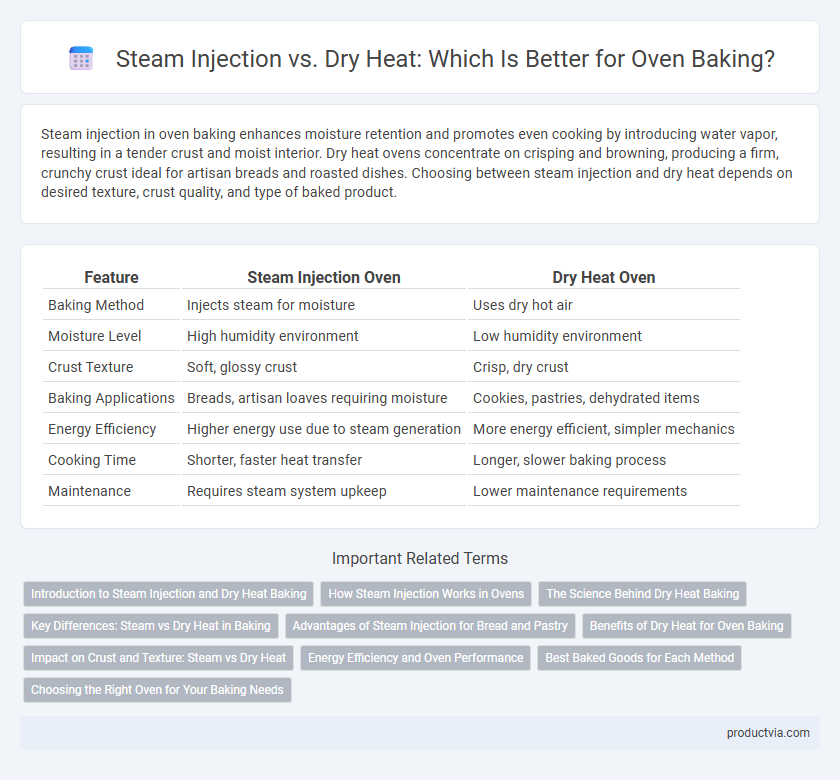

Steam injection in oven baking enhances moisture retention and promotes even cooking by introducing water vapor, resulting in a tender crust and moist interior. Dry heat ovens concentrate on crisping and browning, producing a firm, crunchy crust ideal for artisan breads and roasted dishes. Choosing between steam injection and dry heat depends on desired texture, crust quality, and type of baked product.

Table of Comparison

| Feature | Steam Injection Oven | Dry Heat Oven |

|---|---|---|

| Baking Method | Injects steam for moisture | Uses dry hot air |

| Moisture Level | High humidity environment | Low humidity environment |

| Crust Texture | Soft, glossy crust | Crisp, dry crust |

| Baking Applications | Breads, artisan loaves requiring moisture | Cookies, pastries, dehydrated items |

| Energy Efficiency | Higher energy use due to steam generation | More energy efficient, simpler mechanics |

| Cooking Time | Shorter, faster heat transfer | Longer, slower baking process |

| Maintenance | Requires steam system upkeep | Lower maintenance requirements |

Introduction to Steam Injection and Dry Heat Baking

Steam injection in oven baking introduces moisture into the chamber, enhancing dough expansion and crust development by promoting gelatinization and Maillard reactions. Dry heat baking relies solely on hot air circulation, producing a crispier, drier crust ideal for pastries requiring a flaky texture. Understanding the benefits of steam injection versus dry heat allows bakers to optimize texture and appearance based on specific recipes and desired outcomes.

How Steam Injection Works in Ovens

Steam injection in ovens introduces water vapor directly into the baking chamber, creating a high-humidity environment that promotes even heat distribution and prevents surface drying. This moisture enhances dough expansion by gelatinizing starches and delaying crust formation, resulting in improved volume and a glossy, crisp crust. Precise control of steam timing and intensity allows for optimal texture and browning in baked goods.

The Science Behind Dry Heat Baking

Dry heat baking relies on the process of convection and radiation to transfer heat, causing the Maillard reaction that develops complex flavors and a crisp crust in baked goods. This method evaporates moisture from the food's surface, creating a dry environment essential for browning and texture formation. Unlike steam injection, dry heat lacks humidity, which results in a more pronounced crust formation and deeper caramelization during baking.

Key Differences: Steam vs Dry Heat in Baking

Steam injection in oven baking creates a moist environment that enhances crust development and improves oven spring for bread, resulting in a glossy, crisp exterior. Dry heat baking relies on hot air circulation, which produces a drier crust and is ideal for pastries and baked goods requiring a firm texture. The key difference lies in moisture retention and heat transfer, where steam promotes humidity and expansion, while dry heat ensures even browning and crispiness.

Advantages of Steam Injection for Bread and Pastry

Steam injection in oven baking enhances crust development and improves volume in bread and pastry by creating a humid environment that delays crust formation. This moisture promotes better oven spring, resulting in lighter, airier textures and a glossy, crisp crust. Steam also aids in even heat distribution and slows moisture loss, ensuring optimal crumb structure and extended freshness.

Benefits of Dry Heat for Oven Baking

Dry heat baking in ovens ensures even cooking by circulating hot air, which promotes the Maillard reaction to achieve a crisp, golden crust and enhanced flavor. It reduces moisture content, resulting in a firmer texture ideal for baked goods like bread, cookies, and pastries. This method also supports longer shelf life by minimizing sogginess and preserving structural integrity.

Impact on Crust and Texture: Steam vs Dry Heat

Steam injection in ovens enhances crust formation by creating a moist environment that delays the setting of the crust, allowing it to expand fully and develop a glossy, crispy exterior with a tender crumb. In contrast, dry heat ovens promote rapid crust formation, resulting in a thicker, crunchier crust but may lead to a drier, denser interior texture. The choice between steam and dry heat significantly influences the final product's texture, with steam injection favored for artisan bread and pastries requiring a delicate, chewy crust.

Energy Efficiency and Oven Performance

Steam injection ovens enhance baking quality by maintaining consistent moisture levels, improving crust texture, and reducing baking time, which leads to lower overall energy consumption. Dry heat ovens, while simpler, often cause uneven moisture evaporation and longer baking cycles, resulting in higher energy use to achieve desired results. Optimizing steam injection systems in commercial ovens maximizes energy efficiency and ensures superior oven performance through precise temperature and humidity control.

Best Baked Goods for Each Method

Steam injection ovens excel in baking artisan breads like sourdough and baguettes by creating a humid environment that promotes crust development and oven spring. Dry heat ovens are ideal for items such as cookies, cakes, and pastries, where crisp textures and even browning are essential. Choosing steam injection or dry heat depends on the desired crust and crumb characteristics of the baked goods.

Choosing the Right Oven for Your Baking Needs

Steam injection ovens enhance moisture retention and improve crust texture, making them ideal for artisan breads and delicate pastries. Dry heat ovens provide consistent, high-temperature baking suited for roasting and crisping without added humidity. Selecting the right oven depends on the desired baking outcome, whether moisture-rich crumb structure or a crisp, golden exterior.

Steam Injection vs Dry Heat for Oven Baking Infographic

productvia.com

productvia.com