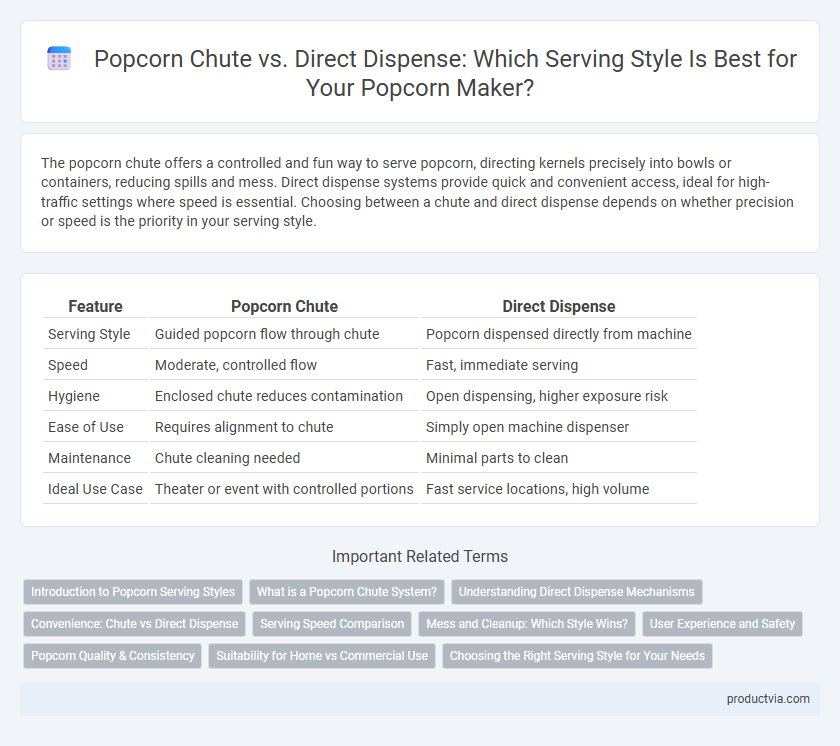

The popcorn chute offers a controlled and fun way to serve popcorn, directing kernels precisely into bowls or containers, reducing spills and mess. Direct dispense systems provide quick and convenient access, ideal for high-traffic settings where speed is essential. Choosing between a chute and direct dispense depends on whether precision or speed is the priority in your serving style.

Table of Comparison

| Feature | Popcorn Chute | Direct Dispense |

|---|---|---|

| Serving Style | Guided popcorn flow through chute | Popcorn dispensed directly from machine |

| Speed | Moderate, controlled flow | Fast, immediate serving |

| Hygiene | Enclosed chute reduces contamination | Open dispensing, higher exposure risk |

| Ease of Use | Requires alignment to chute | Simply open machine dispenser |

| Maintenance | Chute cleaning needed | Minimal parts to clean |

| Ideal Use Case | Theater or event with controlled portions | Fast service locations, high volume |

Introduction to Popcorn Serving Styles

Popcorn serving styles vary primarily between using a popcorn chute and direct dispense methods, each offering distinct advantages for different venues. A popcorn chute provides a controlled, hygienic transfer of popcorn from the machine to the serving container, minimizing spillage and enhancing customer experience in high-traffic environments. Direct dispense allows for a faster, more hands-on serving style, ideal for smaller settings where customization and speed are prioritized.

What is a Popcorn Chute System?

A popcorn chute system is a specialized serving method where popcorn is funneled through a narrow tube or chute directly into bags or containers, ensuring efficient portion control and minimizing mess. This system contrasts with direct dispense serving, where popcorn is manually scooped or poured into containers, often leading to inconsistent portions and increased spillage. Popcorn chute systems are favored in high-volume settings like cinemas and concession stands for their speed, hygiene, and reduced product waste.

Understanding Direct Dispense Mechanisms

Direct dispense mechanisms in popcorn makers utilize a chute system that channels freshly popped kernels directly from the popping chamber to the serving container without manual intervention. This design enhances serving efficiency by reducing spillage and ensuring consistent portion sizes, improving customer experience in high-traffic environments. By streamlining the flow of popcorn, direct dispense systems minimize handling time and maintain optimal product freshness compared to traditional open-basin serving styles.

Convenience: Chute vs Direct Dispense

Popcorn chutes enhance convenience by guiding freshly popped kernels directly into serving containers, reducing spillage and mess for a cleaner operation. Direct dispense models offer faster serving with one-touch release mechanisms but may require more precise positioning to avoid popcorn waste. Choosing between chute and direct dispense depends on the desired balance of speed and cleanliness in popcorn service environments.

Serving Speed Comparison

Popcorn chutes enhance serving speed by allowing continuous flow from the machine directly into containers, minimizing wait times during high-demand periods. Direct dispense methods often require manual scooping, which slows service and increases customer wait times. Implementing a chute system significantly boosts efficiency in busy venues by streamlining the popcorn transfer process.

Mess and Cleanup: Which Style Wins?

A popcorn chute minimizes mess by directing popcorn into a bowl or container, reducing spillage and stray kernels compared to direct dispense machines that release popcorn straight into open serving areas. Cleanup is more efficient with chute systems as they contain the popcorn flow, preventing popcorn and oil residues from spreading across surfaces. Direct dispense models often require more frequent cleaning of countertops and surrounding areas due to scattered kernels and butter splatters.

User Experience and Safety

Popcorn chutes provide a controlled and hygienic way to serve popcorn by directing kernels safely into bags or containers, minimizing mess and contamination. Direct dispense methods offer quicker access but may increase the risk of spillage and user burns due to hot popcorn falling freely. Prioritizing user experience, chutes reduce handling risk and improve portion accuracy, enhancing safety while maintaining efficient service.

Popcorn Quality & Consistency

A popcorn chute system ensures uniform kernel flow, reducing the risk of crushed or burnt popcorn and maintaining consistent shape and texture. Direct dispense methods may cause uneven kernel distribution, leading to variable popping results and compromised popcorn quality. Optimizing serving style with a chute enhances freshness and delivers a consistently high-quality popcorn experience.

Suitability for Home vs Commercial Use

Popcorn chutes provide controlled, hygienic dispensing ideal for commercial settings where high volume and customer interaction demand efficiency and cleanliness. Direct dispense systems offer simplicity and speed, making them suitable for home use where portion control and space-saving are priorities. Choosing between a popcorn chute and direct dispense depends on the environment's scale and the need for operational precision versus convenience.

Choosing the Right Serving Style for Your Needs

Choosing between a popcorn chute and direct dispense serving style depends on your service environment and volume needs. Popcorn chutes provide controlled portions and reduce spillage, ideal for high-traffic venues like movie theaters or concession stands. Direct dispense offers faster access and simplicity, making it suitable for casual or smaller settings where speed and ease of use are priorities.

Popcorn chute vs direct dispense for serving style Infographic

productvia.com

productvia.com