A popcorn maker pet with a nonstick chamber offers effortless cleanup by preventing kernels and oil from adhering to the surface, reducing scrubbing time. In contrast, stainless steel chambers provide durability and resistance to corrosion but may require more thorough cleaning to remove stuck-on residues. Choosing between these depends on whether ease of cleaning or long-term toughness is your priority.

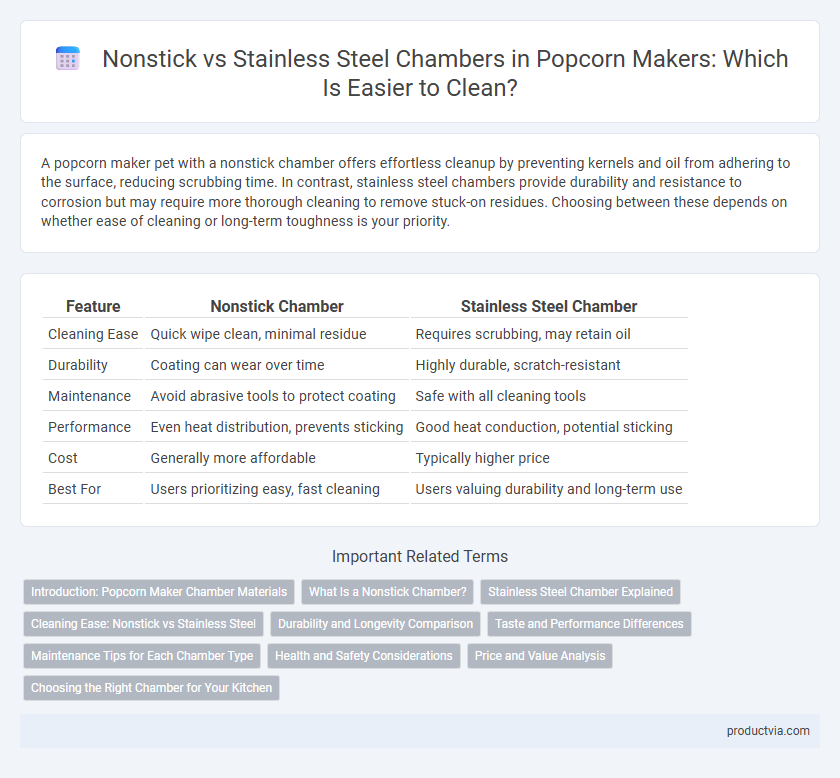

Table of Comparison

| Feature | Nonstick Chamber | Stainless Steel Chamber |

|---|---|---|

| Cleaning Ease | Quick wipe clean, minimal residue | Requires scrubbing, may retain oil |

| Durability | Coating can wear over time | Highly durable, scratch-resistant |

| Maintenance | Avoid abrasive tools to protect coating | Safe with all cleaning tools |

| Performance | Even heat distribution, prevents sticking | Good heat conduction, potential sticking |

| Cost | Generally more affordable | Typically higher price |

| Best For | Users prioritizing easy, fast cleaning | Users valuing durability and long-term use |

Introduction: Popcorn Maker Chamber Materials

Popcorn maker chambers are commonly made from nonstick coatings or stainless steel, each offering distinct cleaning advantages. Nonstick chambers prevent popcorn and oil from adhering, allowing for quick and effortless cleanup with minimal residue. Stainless steel chambers, while requiring more attention during cleaning, provide durability and resist staining, making them a long-lasting option for intensive use.

What Is a Nonstick Chamber?

A nonstick chamber in a popcorn maker features a coating that prevents popcorn and oil from sticking to the surface, significantly simplifying the cleaning process. This type of chamber reduces residue buildup, allowing for quick and effortless maintenance compared to stainless steel chambers. While stainless steel chambers are durable and resistant to corrosion, nonstick coatings enhance user convenience by enabling food particles to be wiped away with minimal effort.

Stainless Steel Chamber Explained

A stainless steel chamber in a popcorn maker offers superior durability and resists rust and corrosion, ensuring long-lasting performance. Unlike nonstick chambers, stainless steel does not suffer from coating wear or peeling, making it safer for health-conscious users. Its smooth surface allows for easy cleaning by hand or dishwasher, maintaining hygiene without the risk of chemical buildup associated with nonstick coatings.

Cleaning Ease: Nonstick vs Stainless Steel

A nonstick chamber in a popcorn maker offers superior cleaning ease by preventing kernels and oil from adhering to the surface, allowing for quick and effortless rinsing. Stainless steel chambers, while durable and resistant to stains, often require more vigorous scrubbing and specialized cleaners to remove residue effectively. Choosing a nonstick chamber significantly reduces cleaning time and maintains optimal performance with minimal maintenance.

Durability and Longevity Comparison

Nonstick chambers in popcorn makers offer easy residue release and quick cleaning but tend to wear down and lose effectiveness over time, potentially leading to chipping or peeling. Stainless steel chambers provide superior durability and longevity, resisting scratches and corrosion while maintaining performance despite frequent use and cleaning. Investing in stainless steel ensures sustained popcorn maker efficiency with minimal maintenance challenges.

Taste and Performance Differences

A nonstick chamber in a popcorn maker allows for effortless cleaning and prevents kernels from sticking, ensuring consistently crisp popcorn without burning. Stainless steel chambers, while slightly harder to clean, provide superior heat distribution that can enhance flavor development and deliver evenly popped kernels. Taste differences are subtle but noticeable, with stainless steel often producing a purer, less oily flavor compared to the occasional residue taste from nonstick coatings.

Maintenance Tips for Each Chamber Type

Nonstick chambers offer effortless cleaning by preventing popcorn and oil from sticking, allowing quick wipe-downs with a soft cloth and mild detergent. Stainless steel chambers require regular soaking in warm, soapy water and gentle scrubbing to remove residue while avoiding abrasive materials that could scratch the surface. For prolonged durability, ensure both chamber types are dried thoroughly and stored in a dry environment to prevent moisture damage and maintain optimal performance.

Health and Safety Considerations

A nonstick chamber in popcorn makers offers easy cleaning but may degrade with frequent use, potentially releasing harmful chemicals if scratched or overheated. Stainless steel chambers provide durability and resist corrosion, ensuring safer cooking without chemical leaching, though they might require more effort to clean. Prioritizing stainless steel chambers supports health and safety by minimizing exposure to toxins and maintaining material integrity over time.

Price and Value Analysis

Nonstick chambers in popcorn makers typically cost less and offer easier cleanup due to their smooth, coated surfaces that prevent popcorn from sticking. Stainless steel chambers, though often pricier, provide superior durability and resist staining and odor retention, delivering long-term value despite more intensive cleaning. Choosing between nonstick and stainless steel depends on budget preference and the desired balance between initial cost and maintenance effort.

Choosing the Right Chamber for Your Kitchen

Nonstick chambers in popcorn makers offer effortless cleaning by preventing kernels and oil from sticking, reducing residue buildup. Stainless steel chambers provide durability and resist rust, but typically require more thorough scrubbing to remove stuck-on food particles. Selecting the right chamber depends on your preference for maintenance ease versus long-term durability in your kitchen.

Nonstick Chamber vs Stainless Steel Chamber for Easy Cleaning Infographic

productvia.com

productvia.com