Aluminum pressure cookers heat up quickly and offer excellent heat conductivity, making them energy-efficient for fast cooking. Stainless steel pressure cookers, on the other hand, provide superior durability, resistance to corrosion, and a sleek appearance, ensuring long-lasting performance. Choosing between aluminum and stainless steel depends on your priorities for heat efficiency versus strength and maintenance.

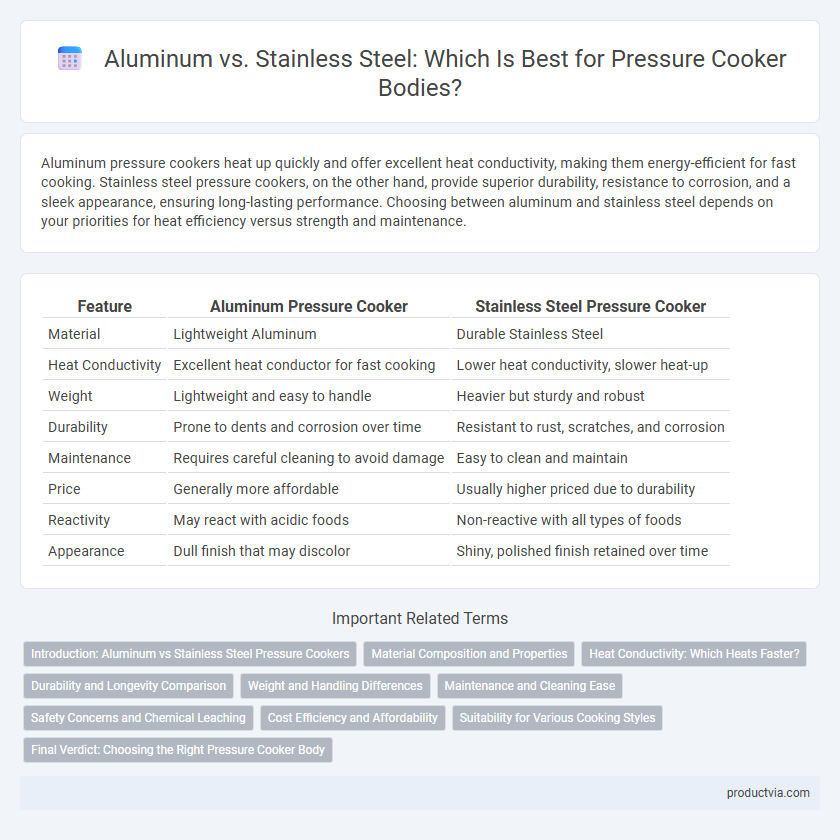

Table of Comparison

| Feature | Aluminum Pressure Cooker | Stainless Steel Pressure Cooker |

|---|---|---|

| Material | Lightweight Aluminum | Durable Stainless Steel |

| Heat Conductivity | Excellent heat conductor for fast cooking | Lower heat conductivity, slower heat-up |

| Weight | Lightweight and easy to handle | Heavier but sturdy and robust |

| Durability | Prone to dents and corrosion over time | Resistant to rust, scratches, and corrosion |

| Maintenance | Requires careful cleaning to avoid damage | Easy to clean and maintain |

| Price | Generally more affordable | Usually higher priced due to durability |

| Reactivity | May react with acidic foods | Non-reactive with all types of foods |

| Appearance | Dull finish that may discolor | Shiny, polished finish retained over time |

Introduction: Aluminum vs Stainless Steel Pressure Cookers

Aluminum pressure cookers offer excellent heat conductivity, allowing for faster cooking times and energy efficiency. Stainless steel pressure cookers provide superior durability, resistance to corrosion, and a sleek appearance, making them ideal for long-term use. Selecting between aluminum and stainless steel depends on priorities such as cooking speed, maintenance, and longevity.

Material Composition and Properties

Aluminum pressure cooker bodies offer excellent thermal conductivity and lightweight properties, ensuring rapid and even heat distribution for efficient cooking. Stainless steel bodies provide superior durability, corrosion resistance, and a non-reactive surface, making them ideal for acidic or varied ingredients. The choice between aluminum and stainless steel depends on the balance between heat performance and long-term resilience needed in the pressure cooker.

Heat Conductivity: Which Heats Faster?

Aluminum pressure cooker bodies heat faster due to aluminum's superior thermal conductivity, which is approximately 237 W/mK compared to stainless steel's 16 W/mK. This high heat conductivity enables aluminum cookers to reach the desired pressure quickly, improving cooking efficiency. Stainless steel bodies, while more durable and resistant to corrosion, require more time to heat up because of their lower thermal conductivity.

Durability and Longevity Comparison

Stainless steel pressure cookers offer superior durability and resistance to corrosion compared to aluminum, which can warp or discolor over time under high heat. The robust construction of stainless steel ensures longer-lasting performance, maintaining structural integrity even after years of frequent use. Aluminum pressure cookers, while lighter and better heat conductors, generally have shorter longevity due to their susceptibility to dents and surface degradation.

Weight and Handling Differences

Aluminum pressure cooker bodies are significantly lighter than stainless steel, making them easier to handle and ideal for quick maneuvering in the kitchen. Stainless steel pressure cookers, while heavier, offer superior durability and resistance to corrosion, providing long-lasting performance. Weight differences affect portability and heat conduction, with aluminum heating faster but stainless steel delivering more even cooking results.

Maintenance and Cleaning Ease

Aluminum pressure cookers are lightweight and conduct heat efficiently, but they require careful maintenance to avoid discoloration and corrosion, especially with acidic foods. Stainless steel pressure cookers offer superior durability and resistance to rust, making them easier to clean and maintain without the risk of warping or reacting with ingredients. Choosing stainless steel reduces long-term upkeep efforts due to its non-porous surface that resists stains and retains its polished look after repeated cleaning.

Safety Concerns and Chemical Leaching

Aluminum pressure cookers are prone to chemical leaching, especially when cooking acidic foods, raising safety concerns due to aluminum's potential health risks. Stainless steel pressure cookers offer superior resistance to corrosion and do not leach harmful substances, making them a safer choice for food preparation. Choosing stainless steel enhances durability and maintains food purity, avoiding aluminum's possible contamination issues.

Cost Efficiency and Affordability

Aluminum pressure cooker bodies are generally more cost-efficient due to their lower material and manufacturing expenses, making them an affordable choice for budget-conscious buyers. Stainless steel bodies, while more expensive upfront, offer enhanced durability and resistance to corrosion, potentially reducing replacement costs over time. Evaluating long-term use and maintenance expenses is crucial when deciding between aluminum's affordability and stainless steel's longevity.

Suitability for Various Cooking Styles

Aluminum pressure cookers heat up quickly and provide excellent thermal conductivity, making them ideal for fast cooking and recipes requiring precise temperature control, such as Indian dals and vegetables. Stainless steel pressure cookers, known for durability and resistance to corrosion, excel in slow-cooking and high-pressure recipes like stews and meats, as they maintain consistent heat distribution over prolonged periods. Both materials suit different cooking styles, with aluminum favored for quick tasks and stainless steel preferred for robust, long-duration cooking.

Final Verdict: Choosing the Right Pressure Cooker Body

Aluminum pressure cookers heat up quickly and provide excellent heat conductivity, making them energy-efficient and affordable options for everyday cooking. Stainless steel pressure cookers offer superior durability, resistance to corrosion, and are often dishwasher safe, ensuring long-term use and easy maintenance. For users prioritizing lightweight and efficient cooking, aluminum is ideal, while those seeking robustness and longevity should opt for stainless steel pressure cookers.

Aluminum vs Stainless Steel for Pressure Cooker Body Infographic

productvia.com

productvia.com