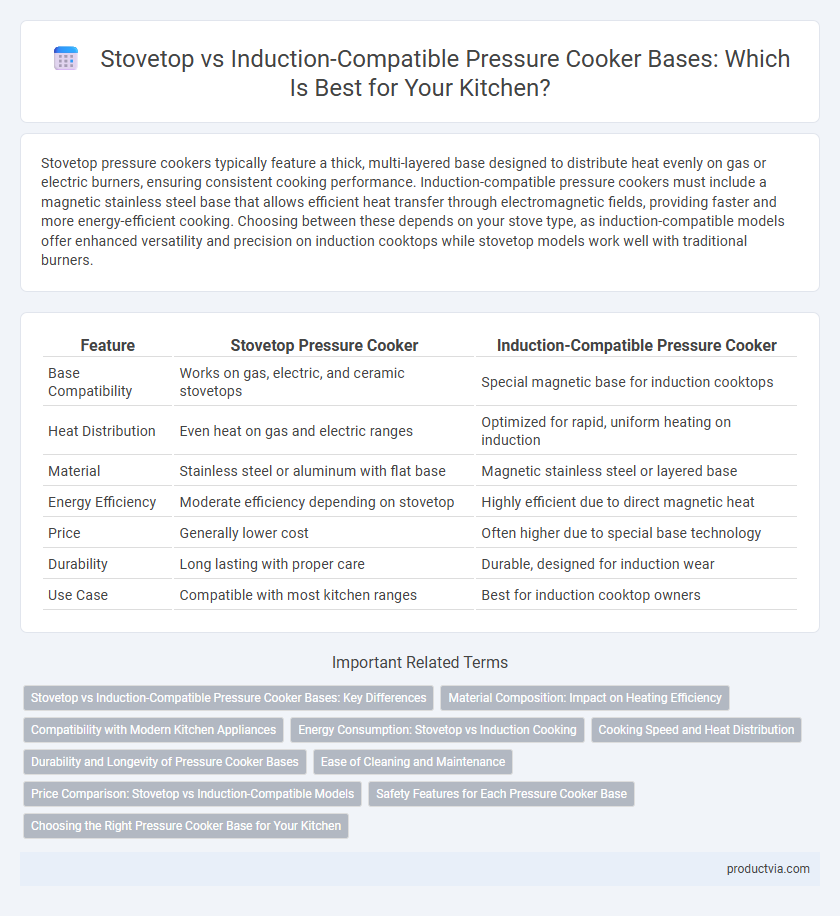

Stovetop pressure cookers typically feature a thick, multi-layered base designed to distribute heat evenly on gas or electric burners, ensuring consistent cooking performance. Induction-compatible pressure cookers must include a magnetic stainless steel base that allows efficient heat transfer through electromagnetic fields, providing faster and more energy-efficient cooking. Choosing between these depends on your stove type, as induction-compatible models offer enhanced versatility and precision on induction cooktops while stovetop models work well with traditional burners.

Table of Comparison

| Feature | Stovetop Pressure Cooker | Induction-Compatible Pressure Cooker |

|---|---|---|

| Base Compatibility | Works on gas, electric, and ceramic stovetops | Special magnetic base for induction cooktops |

| Heat Distribution | Even heat on gas and electric ranges | Optimized for rapid, uniform heating on induction |

| Material | Stainless steel or aluminum with flat base | Magnetic stainless steel or layered base |

| Energy Efficiency | Moderate efficiency depending on stovetop | Highly efficient due to direct magnetic heat |

| Price | Generally lower cost | Often higher due to special base technology |

| Durability | Long lasting with proper care | Durable, designed for induction wear |

| Use Case | Compatible with most kitchen ranges | Best for induction cooktop owners |

Stovetop vs Induction-Compatible Pressure Cooker Bases: Key Differences

Stovetop pressure cooker bases are typically made from heavy-gauge aluminum or stainless steel, offering excellent heat distribution on gas and electric coil burners. Induction-compatible pressure cooker bases contain a magnetic layer, usually stainless steel or a ferromagnetic material, enabling them to work efficiently on induction cooktops by generating heat through electromagnetic fields. The key difference lies in material composition and heat transfer method, with induction-compatible bases providing faster, more energy-efficient heating and precise temperature control compared to traditional stovetop bases.

Material Composition: Impact on Heating Efficiency

The material composition of a pressure cooker base significantly influences its heating efficiency, with stainless steel and aluminum cores offering optimal heat conduction for stovetop models. Induction-compatible pressure cookers require a ferromagnetic base, typically made from magnetic stainless steel or cast iron, to ensure efficient electromagnetic heat transfer. This difference affects cooking speed and energy usage, as induction bases heat more evenly and rapidly compared to some traditional stovetop materials.

Compatibility with Modern Kitchen Appliances

Pressure cookers with induction-compatible bases use ferromagnetic materials like stainless steel or iron, ensuring efficient heat transfer on induction cooktops commonly found in modern kitchens. Stovetop-only pressure cookers often utilize aluminum bases that are unsuitable for induction, limiting their versatility with contemporary appliances. Choosing an induction-compatible pressure cooker guarantees seamless integration with a wide range of kitchen cooktops, enhancing cooking performance and energy efficiency.

Energy Consumption: Stovetop vs Induction Cooking

Induction-compatible pressure cookers offer superior energy efficiency by directly heating the cookware through electromagnetic energy, reducing heat loss compared to stovetop models that rely on radiant or gas flames. Stovetop pressure cookers often consume more energy due to longer cooking times and uneven heat distribution. Energy consumption is notably lower with induction cooking, resulting in faster pressure build-up and reduced gas or electricity usage.

Cooking Speed and Heat Distribution

Pressure cookers with induction-compatible bases offer faster cooking speeds due to their ability to generate heat more rapidly and maintain consistent temperatures, optimizing pressure build-up. Stovetop pressure cookers may have slower heat response times depending on the burner type, leading to less efficient heat distribution and longer cooking durations. Induction-compatible bases typically provide superior heat distribution across the pressure cooker surface, ensuring even cooking and preventing hot spots.

Durability and Longevity of Pressure Cooker Bases

Pressure cooker bases designed for induction compatibility typically feature a multilayered construction with magnetic stainless steel, enhancing durability and resistance to warping compared to traditional stovetop-only bases. Induction bases maintain consistent heat distribution and reduce wear from frequent temperature fluctuations, extending the pressure cooker's lifespan. Quality pressure cookers with induction-compatible bases often outperform stovetop counterparts in longevity due to their robust materials engineered for high thermal conductivity and scratch resistance.

Ease of Cleaning and Maintenance

Pressure cookers with induction-compatible bases feature smooth, magnetic stainless steel that resists sticking and simplifies cleaning compared to traditional stovetop models, which often have rougher aluminum bases prone to food residue buildup. The durable induction base typically requires less effort for maintenance, as it withstands abrasive scrubbing and frequent washing without damage. Stovetop pressure cookers may demand more careful cleaning to avoid scratching or discoloration, increasing long-term upkeep time and effort.

Price Comparison: Stovetop vs Induction-Compatible Models

Stovetop pressure cooker bases typically cost less than induction-compatible models due to simpler construction and materials. Induction-compatible pressure cookers feature magnetic stainless steel bases, which increase manufacturing costs, resulting in higher retail prices. Consumers often weigh these price differences against energy efficiency and cooking speed benefits offered by induction-compatible models.

Safety Features for Each Pressure Cooker Base

Stovetop pressure cookers typically feature a heavy-duty metal base designed for even heat distribution and include pressure indicators and safety valves to prevent lid opening under pressure, reducing accident risks. Induction-compatible pressure cookers incorporate magnetic stainless steel bases that ensure rapid heating while maintaining compatibility with induction cooktops, equipped with multiple safety mechanisms such as pressure release systems and locking lids that enhance user protection. Both types prioritize safety through robust construction and integrated pressure regulation, but induction models offer added precision control due to their interaction with induction cooktop technology.

Choosing the Right Pressure Cooker Base for Your Kitchen

Selecting the right pressure cooker base depends on your stovetop type, with stovetop models featuring tri-ply or stainless steel bases for even heat distribution on gas or electric burners. Induction-compatible bases require magnetic stainless steel or an encapsulated aluminum core to ensure efficient heat transfer on induction cooktops. Opt for a base that matches your kitchen's cooking technology to maximize energy efficiency and cooking performance.

Stovetop vs Induction-compatible for pressure cooker base Infographic

productvia.com

productvia.com