Gasket-sealed pressure cookers use a rubber or silicone ring to create an airtight seal, ensuring efficient steam retention and safety during cooking. Metal-to-metal seals rely on a precise fit between metal surfaces, offering durability and reduced maintenance but may require more careful handling to maintain a secure seal. Choosing between gasket-sealed and metal-to-metal seals depends on ease of use, long-term reliability, and maintenance preferences.

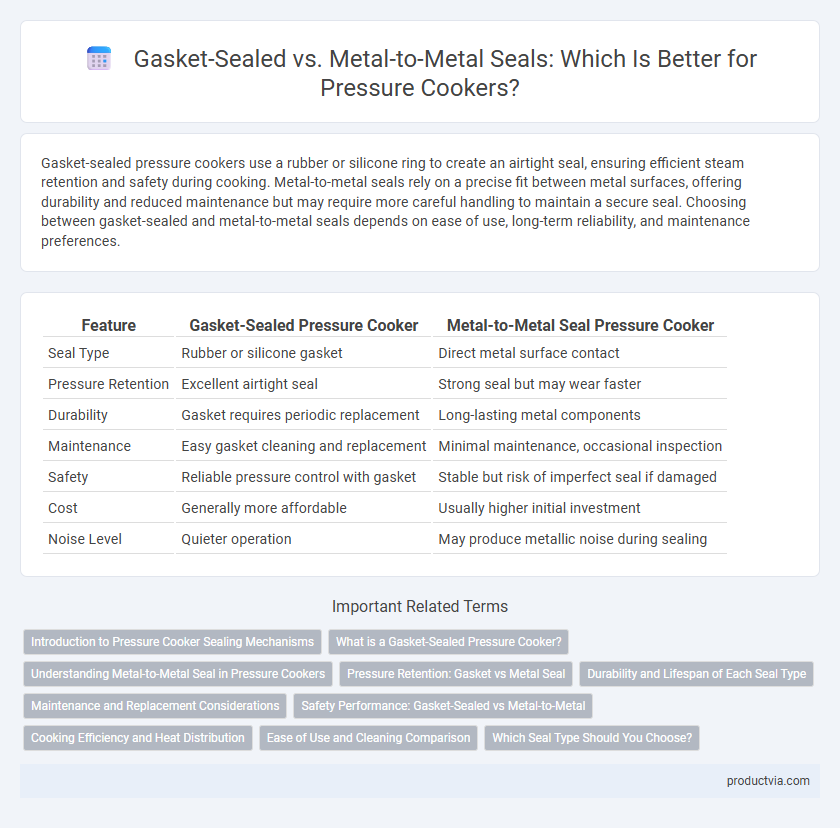

Table of Comparison

| Feature | Gasket-Sealed Pressure Cooker | Metal-to-Metal Seal Pressure Cooker |

|---|---|---|

| Seal Type | Rubber or silicone gasket | Direct metal surface contact |

| Pressure Retention | Excellent airtight seal | Strong seal but may wear faster |

| Durability | Gasket requires periodic replacement | Long-lasting metal components |

| Maintenance | Easy gasket cleaning and replacement | Minimal maintenance, occasional inspection |

| Safety | Reliable pressure control with gasket | Stable but risk of imperfect seal if damaged |

| Cost | Generally more affordable | Usually higher initial investment |

| Noise Level | Quieter operation | May produce metallic noise during sealing |

Introduction to Pressure Cooker Sealing Mechanisms

Pressure cookers use two primary sealing mechanisms: gasket-sealed and metal-to-metal seals. Gasket-sealed designs employ a flexible rubber or silicone ring to create an airtight barrier, ensuring consistent pressure buildup during cooking. Metal-to-metal seals rely on precision-machined surfaces to form a durable, high-pressure seal, often found in professional-grade pressure cookers.

What is a Gasket-Sealed Pressure Cooker?

A gasket-sealed pressure cooker uses a flexible rubber or silicone gasket to create an airtight seal between the lid and the pot, ensuring steam is trapped inside for efficient cooking. This type of seal enhances safety by preventing pressure leaks and allows for consistent heat retention. Gasket-sealed models are more common due to their reliable sealing performance and ease of maintenance compared to metal-to-metal seals.

Understanding Metal-to-Metal Seal in Pressure Cookers

Metal-to-metal seals in pressure cookers ensure a durable, high-pressure-resistant closure by directly mating the metal lid to the pot, eliminating reliance on a gasket for sealing. This design reduces the risk of gasket wear and tear, extends the cookware's lifespan, and provides consistent pressure retention for safer cooking. Metal-to-metal sealed pressure cookers typically require precise engineering and maintenance to maintain an airtight seal compared to gasket-sealed models.

Pressure Retention: Gasket vs Metal Seal

Gasket-sealed pressure cookers provide superior pressure retention due to the flexible rubber or silicone gasket that creates an airtight seal, preventing steam from escaping during cooking. Metal-to-metal seals offer durability and are less prone to wear over time but may allow minimal steam leakage, reducing overall pressure retention efficiency. Choosing between gasket-sealed and metal-to-metal seals directly impacts the cooker's ability to maintain consistent pressure, influencing cooking speed and energy efficiency.

Durability and Lifespan of Each Seal Type

Gasket-sealed pressure cookers offer excellent airtight sealing with flexible rubber or silicone gaskets that require periodic replacement due to wear and tear, impacting their lifespan. Metal-to-metal seals provide superior durability and longer lifespan because they rely on precise machined surfaces without rubber components, reducing maintenance needs. Pressure cookers with metal-to-metal seals typically last significantly longer under frequent use, while gasket-sealed models require routine gasket inspections and replacements to maintain safety and performance.

Maintenance and Replacement Considerations

Gasket-sealed pressure cookers require regular inspection and replacement of the rubber or silicone gasket to maintain an airtight seal and prevent steam leaks, typically every 12 to 18 months depending on usage. Metal-to-metal seal pressure cookers feature durable construction that demands less frequent maintenance but may require professional servicing to address wear or deformation of sealing surfaces. Proper maintenance ensures optimal safety and performance, with gasket seals being more user-friendly for DIY replacement compared to the specialized care needed for metal-to-metal seals.

Safety Performance: Gasket-Sealed vs Metal-to-Metal

Gasket-sealed pressure cookers use a flexible rubber or silicone gasket to create an airtight seal, providing reliable pressure retention and reducing the risk of steam leaks, which enhances safety by preventing sudden pressure drops. Metal-to-metal seals rely on precise machining and metal surfaces to maintain pressure, offering a durable and heat-resistant seal but requiring exact fit and maintenance to avoid potential safety hazards from imperfect sealing. In terms of safety performance, gasket-sealed valves generally offer more consistent pressure regulation and user alerts, while metal-to-metal seals prioritize durability and longevity under high-pressure conditions.

Cooking Efficiency and Heat Distribution

Gasket-sealed pressure cookers provide superior cooking efficiency by maintaining a tight, flexible seal that minimizes steam loss and ensures consistent internal pressure. Metal-to-metal seals offer enhanced durability but may allow slight steam leakage, potentially reducing heat retention and causing uneven heat distribution. Reliable gasket seals contribute to faster cooking times and more uniform heat, optimizing food texture and flavor development.

Ease of Use and Cleaning Comparison

Gasket-sealed pressure cookers offer ease of use with a flexible rubber or silicone ring that ensures a tight seal and can be easily removed for cleaning, preventing food buildup. Metal-to-metal seal models require precise alignment and more maintenance to maintain the integrity of the seal but avoid gasket wear and potential odor retention. Cleaning gasket-sealed cookers is generally simpler due to detachable components, while metal-to-metal seals may need thorough inspection to prevent residue and ensure consistent performance.

Which Seal Type Should You Choose?

Gasket-sealed pressure cookers provide a reliable and airtight seal using a flexible rubber or silicone gasket, ideal for most home cooking as they maintain consistent pressure and are easy to replace. Metal-to-metal seal pressure cookers offer durability and high heat resistance with a seamless design that requires less maintenance and suits advanced users who prioritize long-term use and safety. Choosing between these depends on your cooking frequency, maintenance willingness, and preference for ease of use versus durability.

Gasket-sealed vs Metal-to-metal seal for pressure cooker Infographic

productvia.com

productvia.com