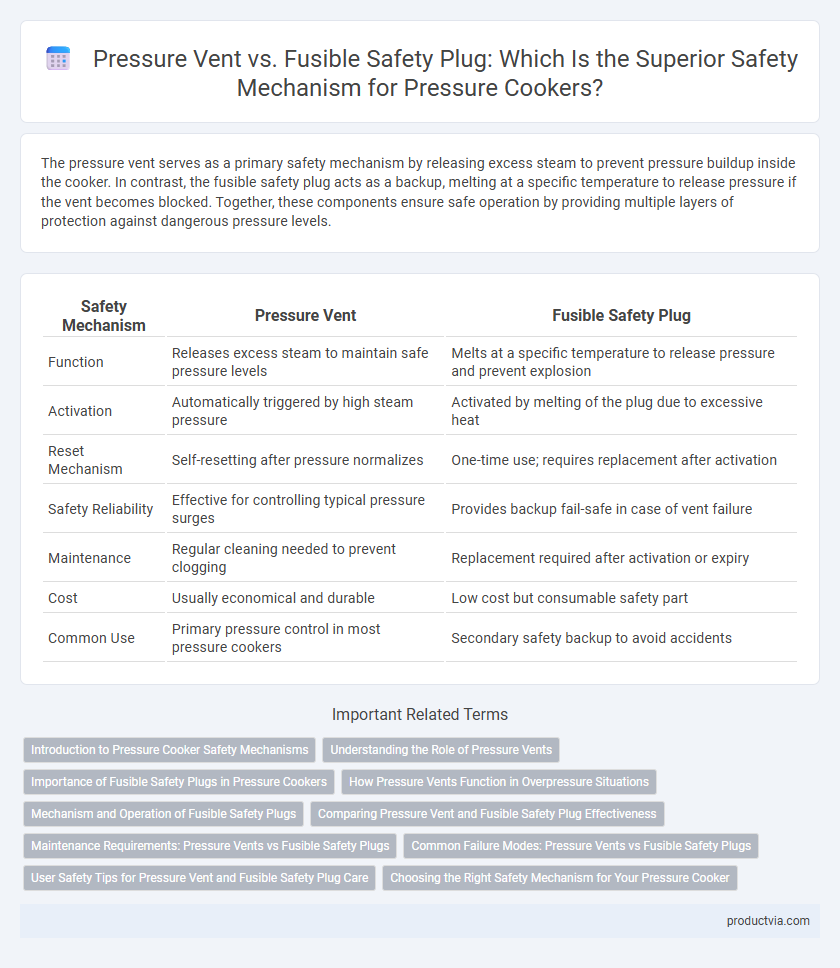

The pressure vent serves as a primary safety mechanism by releasing excess steam to prevent pressure buildup inside the cooker. In contrast, the fusible safety plug acts as a backup, melting at a specific temperature to release pressure if the vent becomes blocked. Together, these components ensure safe operation by providing multiple layers of protection against dangerous pressure levels.

Table of Comparison

| Safety Mechanism | Pressure Vent | Fusible Safety Plug |

|---|---|---|

| Function | Releases excess steam to maintain safe pressure levels | Melts at a specific temperature to release pressure and prevent explosion |

| Activation | Automatically triggered by high steam pressure | Activated by melting of the plug due to excessive heat |

| Reset Mechanism | Self-resetting after pressure normalizes | One-time use; requires replacement after activation |

| Safety Reliability | Effective for controlling typical pressure surges | Provides backup fail-safe in case of vent failure |

| Maintenance | Regular cleaning needed to prevent clogging | Replacement required after activation or expiry |

| Cost | Usually economical and durable | Low cost but consumable safety part |

| Common Use | Primary pressure control in most pressure cookers | Secondary safety backup to avoid accidents |

Introduction to Pressure Cooker Safety Mechanisms

Pressure cooker safety mechanisms primarily include pressure vents and fusible safety plugs, both essential for preventing excessive internal pressure buildup. Pressure vents automatically release steam when pressure exceeds safe levels, ensuring continuous regulation. Fusible safety plugs act as a secondary safety measure by melting at a specific temperature to release pressure and prevent potential explosions.

Understanding the Role of Pressure Vents

Pressure vents regulate internal pressure by releasing excess steam, preventing dangerous pressure buildup in pressure cookers. Fusible safety plugs serve as a backup, melting at specific temperatures to release pressure if the vent fails. Understanding the role of pressure vents is crucial for maintaining cooker safety and ensuring reliable pressure regulation during cooking.

Importance of Fusible Safety Plugs in Pressure Cookers

Fusible safety plugs serve as a critical backup safety mechanism in pressure cookers by melting at a specific temperature to release excess pressure, preventing potential explosions when the pressure vent is blocked or malfunctioning. Unlike pressure vents, which regulate normal pressure levels during cooking, fusible plugs provide an emergency release, enhancing overall safety. Their importance lies in mitigating risks by ensuring the cooker does not exceed hazardous pressure and temperature thresholds.

How Pressure Vents Function in Overpressure Situations

Pressure vents in pressure cookers serve as a critical safety mechanism by releasing excess steam when internal pressure exceeds safe levels, preventing potential explosions. These vents operate by opening at predetermined pressure thresholds, allowing steam to escape until the pressure stabilizes within the cooker. Unlike fusible safety plugs that melt under high heat to release pressure, pressure vents provide a reusable, immediate pressure relief function essential for continuous safe cooking operations.

Mechanism and Operation of Fusible Safety Plugs

Fusible safety plugs in pressure cookers operate by incorporating a heat-sensitive alloy that melts at a predetermined temperature, releasing steam to prevent excessive pressure buildup. This mechanism acts as a fail-safe, activating only when the pressure vent is blocked or malfunctioning, ensuring cooker integrity and user safety. Unlike pressure vents that regulate pressure during normal operation, fusible plugs provide emergency pressure release by permanently opening upon reaching critical temperature thresholds.

Comparing Pressure Vent and Fusible Safety Plug Effectiveness

Pressure vents regulate internal pressure by releasing steam when a preset threshold is reached, offering consistent safety by preventing excessive pressure build-up in pressure cookers. Fusible safety plugs melt at specific temperatures to release steam, providing a fail-safe mechanism in case the primary vent fails, but they are single-use and require replacement after activation. Comparing effectiveness, pressure vents provide continuous pressure regulation, while fusible plugs act as a critical backup, ensuring comprehensive safety through a dual-layer approach.

Maintenance Requirements: Pressure Vents vs Fusible Safety Plugs

Pressure vents require regular inspection and cleaning to ensure they remain free of blockages that could impede steam release, maintaining optimal pressure levels and preventing accidents. Fusible safety plugs necessitate periodic replacement after exposure to high temperatures or pressure events, as their metal alloys melt to release pressure and cannot be reused. Proper adherence to these maintenance protocols is essential for the reliable operation and safety of pressure cookers.

Common Failure Modes: Pressure Vents vs Fusible Safety Plugs

Pressure vents commonly fail due to clogging from food debris or mineral buildup, leading to insufficient pressure release and potential overpressure hazards. Fusible safety plugs often degrade over time or become damaged from repeated thermal cycling, risking premature melting or failure to activate under excessive pressure. Regular inspection and maintenance of both components are essential to ensure reliable pressure regulation and cooker safety.

User Safety Tips for Pressure Vent and Fusible Safety Plug Care

Pressure vent and fusible safety plug are critical components in maintaining pressure cooker safety by releasing excess steam to prevent explosions. Users should routinely inspect the pressure vent for blockages and clean it with a brush to ensure unobstructed steam flow. Fusible safety plugs require regular checks for wear or damage and must be replaced immediately if any deformation or melting signs appear to maintain effective pressure release.

Choosing the Right Safety Mechanism for Your Pressure Cooker

Choosing the right safety mechanism for your pressure cooker involves understanding the differences between a pressure vent and a fusible safety plug. A pressure vent automatically releases excess steam to prevent dangerous pressure buildup, making it reliable for frequent use, while a fusible safety plug melts at a specific temperature to provide a fail-safe in case of extreme overheating. Prioritizing pressure vents offers consistent safety for daily cooking, whereas fusible plugs serve as a critical backup, ensuring comprehensive protection.

Pressure vent vs fusible safety plug for safety mechanism Infographic

productvia.com

productvia.com