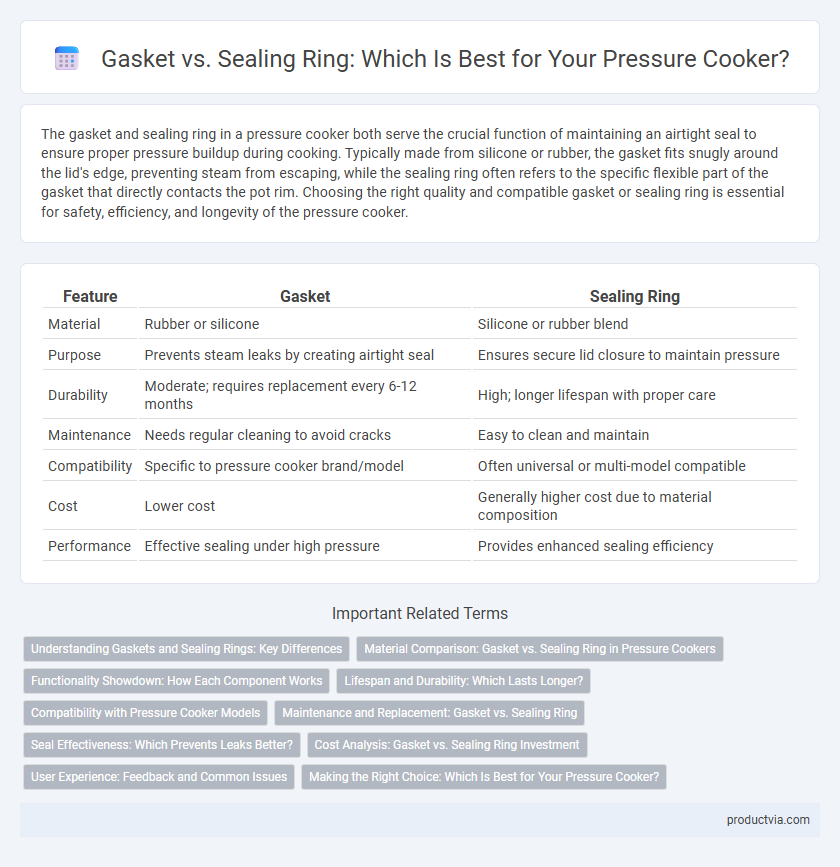

The gasket and sealing ring in a pressure cooker both serve the crucial function of maintaining an airtight seal to ensure proper pressure buildup during cooking. Typically made from silicone or rubber, the gasket fits snugly around the lid's edge, preventing steam from escaping, while the sealing ring often refers to the specific flexible part of the gasket that directly contacts the pot rim. Choosing the right quality and compatible gasket or sealing ring is essential for safety, efficiency, and longevity of the pressure cooker.

Table of Comparison

| Feature | Gasket | Sealing Ring |

|---|---|---|

| Material | Rubber or silicone | Silicone or rubber blend |

| Purpose | Prevents steam leaks by creating airtight seal | Ensures secure lid closure to maintain pressure |

| Durability | Moderate; requires replacement every 6-12 months | High; longer lifespan with proper care |

| Maintenance | Needs regular cleaning to avoid cracks | Easy to clean and maintain |

| Compatibility | Specific to pressure cooker brand/model | Often universal or multi-model compatible |

| Cost | Lower cost | Generally higher cost due to material composition |

| Performance | Effective sealing under high pressure | Provides enhanced sealing efficiency |

Understanding Gaskets and Sealing Rings: Key Differences

Gaskets and sealing rings are critical components that ensure the airtight seal in a pressure cooker, preventing steam from escaping during cooking. The gasket, typically made from durable rubber or silicone, fits around the lid's edge to create the primary seal, while the sealing ring often refers to the same component but can vary in material and design depending on the pressure cooker's brand. Understanding the material composition and fit of both is essential for maintaining pressure cooker safety and performance, as worn or incorrect gaskets or sealing rings can lead to steam leaks and cooking inefficiency.

Material Comparison: Gasket vs. Sealing Ring in Pressure Cookers

Gaskets in pressure cookers are typically made from high-quality silicone, offering excellent heat resistance, flexibility, and durability under high pressure conditions. Sealing rings, often composed of rubber or thermoplastic elastomers, provide strong sealing capabilities but may degrade faster due to lower heat tolerance and chemical resistance. Silicone gaskets generally ensure better longevity and safer performance compared to traditional rubber sealing rings, making them ideal for frequent pressure cooking.

Functionality Showdown: How Each Component Works

The gasket and sealing ring both serve crucial roles in maintaining pressure cooker efficiency, with the gasket acting as a flexible barrier that ensures airtight closure between the lid and pot. The sealing ring, typically made from silicone or rubber, focuses on creating a watertight seal to prevent steam from escaping during cooking. Together, these components work in tandem to stabilize internal pressure, optimize cooking times, and enhance safety.

Lifespan and Durability: Which Lasts Longer?

Pressure cooker gaskets and sealing rings both ensure airtight seals, but silicone sealing rings generally offer superior lifespan and durability compared to traditional rubber gaskets. Silicone sealing rings resist heat, pressure, and wear more effectively, often lasting up to two years or longer with proper care, whereas rubber gaskets typically require replacement every 6 to 12 months due to wear and deformation. Choosing a silicone sealing ring enhances long-term performance and reduces maintenance frequency for pressure cookers.

Compatibility with Pressure Cooker Models

The gasket and sealing ring serve as crucial components in maintaining the airtight pressure within a pressure cooker, each designed to fit specific cooker models. Gaskets are typically made from silicone or rubber, ensuring a tight seal compatible with most standard pressure cookers, while sealing rings often feature a more flexible design tailored for particular brands or multi-layered lids. Choosing the correct gasket or sealing ring that corresponds to the exact pressure cooker model guarantees optimal performance, safety, and longevity of the appliance.

Maintenance and Replacement: Gasket vs. Sealing Ring

The gasket and sealing ring in a pressure cooker require regular inspection and replacement to maintain optimal pressure and safety. Gaskets, typically made from rubber or silicone, can wear out, crack, or become brittle over time, necessitating replacement every 6 to 12 months depending on usage frequency. Sealing rings, often made from silicone or other heat-resistant materials, should be cleaned thoroughly after each use and replaced promptly if they show signs of deformation or loss of elasticity to prevent steam leakage and ensure proper pressure buildup.

Seal Effectiveness: Which Prevents Leaks Better?

The sealing ring in a pressure cooker provides a more flexible and secure seal compared to the gasket, which can sometimes develop gaps under high pressure. Gaskets, often made from rigid materials, may degrade faster and lead to leaks, whereas sealing rings, typically constructed from silicone or rubber, maintain elasticity and ensure airtight pressure retention. For optimal leak prevention and safety, a high-quality sealing ring outperforms traditional gaskets in maintaining an effective pressure cooker seal.

Cost Analysis: Gasket vs. Sealing Ring Investment

The cost analysis between a pressure cooker gasket and sealing ring reveals that gaskets often have a lower upfront investment but may require more frequent replacements due to wear and tear, increasing long-term expenses. Sealing rings, typically made from durable silicone or rubber compounds, involve a higher initial cost but offer extended durability and enhanced pressure retention, potentially reducing overall maintenance costs. Choosing between the two depends on balancing initial budget constraints with lifecycle cost efficiency for optimal pressure cooker performance.

User Experience: Feedback and Common Issues

Pressure cooker gaskets and sealing rings are essential components that ensure a tight seal for safe cooking, but users often report differences in durability and flexibility. Common issues with gaskets include hardening and cracking over time, leading to steam leaks and reduced efficiency, whereas sealing rings tend to have better longevity but may still wear out with frequent use. User feedback frequently emphasizes the importance of regular inspection and timely replacement to maintain optimal pressure cooker performance and prevent safety hazards.

Making the Right Choice: Which Is Best for Your Pressure Cooker?

Choosing between a gasket and a sealing ring for your pressure cooker depends on material compatibility and durability requirements. Gaskets, often made from rubber or silicone, provide a flexible and airtight seal essential for maintaining pressure, while sealing rings are typically more rigid and designed for specific models to ensure safety and efficiency. Selecting the right component ensures optimal cooking performance, prevents leaks, and extends the lifespan of your pressure cooker.

Gasket vs Sealing ring for pressure cooker Infographic

productvia.com

productvia.com