Inner pots with nonstick coatings in pressure cookers offer easy cleanup as food residues slide off effortlessly, reducing scrubbing time. Stainless steel coated pots require more thorough cleaning to remove stuck-on food but are highly durable and resist scratches from metal utensils. Choosing between nonstick and stainless steel coatings balances convenience in cleaning with long-term durability and maintenance preferences.

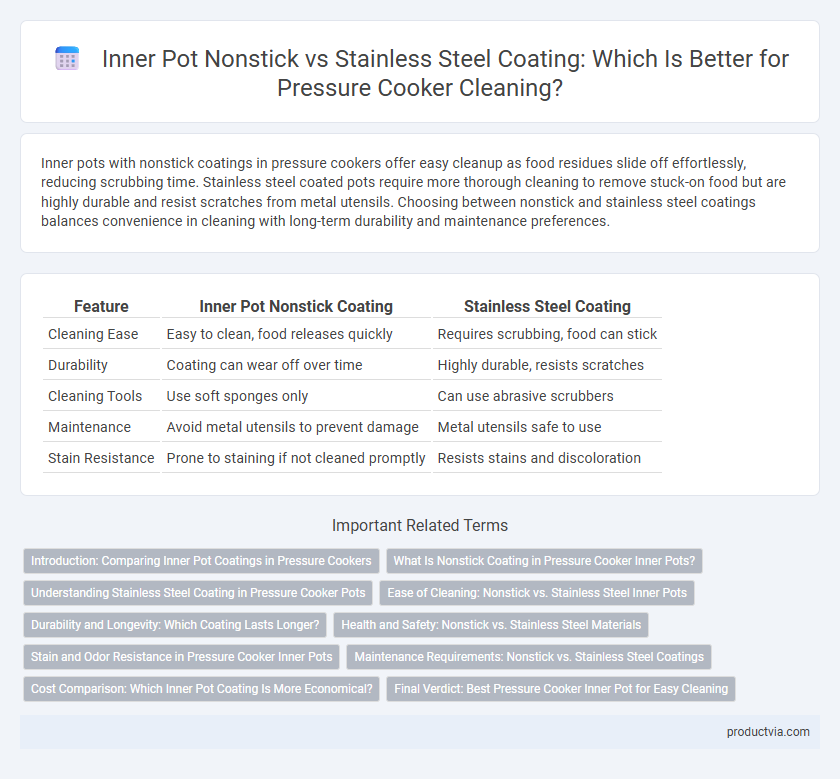

Table of Comparison

| Feature | Inner Pot Nonstick Coating | Stainless Steel Coating |

|---|---|---|

| Cleaning Ease | Easy to clean, food releases quickly | Requires scrubbing, food can stick |

| Durability | Coating can wear off over time | Highly durable, resists scratches |

| Cleaning Tools | Use soft sponges only | Can use abrasive scrubbers |

| Maintenance | Avoid metal utensils to prevent damage | Metal utensils safe to use |

| Stain Resistance | Prone to staining if not cleaned promptly | Resists stains and discoloration |

Introduction: Comparing Inner Pot Coatings in Pressure Cookers

Inner pots with nonstick coatings in pressure cookers provide easy release of food and simplified cleaning due to their smooth surfaces, reducing residue buildup. Stainless steel coated inner pots, while slightly more challenging to clean, offer superior durability, resistance to scratches, and compatibility with metal utensils. Choosing between nonstick and stainless steel coatings affects maintenance routines and long-term performance of the pressure cooker.

What Is Nonstick Coating in Pressure Cooker Inner Pots?

Nonstick coating in pressure cooker inner pots is a specialized surface layer designed to prevent food from adhering during cooking, enhancing ease of cleaning. This coating, typically made from polytetrafluoroethylene (PTFE) or ceramic materials, reduces the need for excessive scrubbing and minimizes residue buildup. Unlike stainless steel, nonstick surfaces offer superior release properties but may require gentle care to maintain coating integrity over time.

Understanding Stainless Steel Coating in Pressure Cooker Pots

Stainless steel coating in pressure cooker pots offers a durable, scratch-resistant surface that withstands high temperatures without peeling or flaking, making it ideal for long-term use. This material resists staining and corrosion, simplifying cleaning processes with just warm water and mild detergent, avoiding the need for abrasive scrubbers. Unlike nonstick coatings that may degrade over time, stainless steel maintains its integrity, ensuring consistent cooking performance and hygiene.

Ease of Cleaning: Nonstick vs. Stainless Steel Inner Pots

Nonstick inner pots in pressure cookers offer superior ease of cleaning due to their smooth surface that prevents food from sticking, reducing scrubbing time significantly. Stainless steel inner pots, while durable and resistant to scratching, often require more effort and elbow grease to remove stuck-on food particles. Selecting a nonstick coating for the inner pot can simplify maintenance and enhance the overall user experience by minimizing cleanup challenges.

Durability and Longevity: Which Coating Lasts Longer?

Nonstick coatings on pressure cooker inner pots offer easy cleaning but tend to wear off over time, reducing their durability and lifespan compared to stainless steel coatings. Stainless steel inner pots are highly resistant to scratches, corrosion, and high temperatures, providing superior longevity and maintaining performance after prolonged use. Choosing stainless steel ensures a more durable pressure cooker inner pot that requires less frequent replacement due to wear.

Health and Safety: Nonstick vs. Stainless Steel Materials

Nonstick coatings in pressure cooker inner pots offer easy cleaning but may release harmful chemicals if scratched or overheated, raising health concerns. Stainless steel materials provide a safer alternative with durable, non-reactive surfaces that prevent contamination and withstand rigorous cleaning without degrading. Prioritizing stainless steel inner pots enhances long-term safety by eliminating risks associated with toxic fumes and coating deterioration.

Stain and Odor Resistance in Pressure Cooker Inner Pots

Nonstick coatings in pressure cooker inner pots offer superior stain resistance, preventing food residues from adhering and making cleaning easier. Stainless steel coatings, while more durable and scratch-resistant, tend to retain stains and odors from intense cooking processes, requiring more rigorous cleaning methods. For stain and odor resistance specifically, nonstick inner pots provide a cleaner cooking experience with less lingering smells over time.

Maintenance Requirements: Nonstick vs. Stainless Steel Coatings

Nonstick coatings on pressure cooker inner pots require gentle cleaning with non-abrasive sponges to maintain their smooth surface and prevent scratching, while stainless steel coatings tolerate more rigorous scrubbing and are resistant to staining and corrosion. Nonstick surfaces often need careful upkeep to avoid peeling or degradation, whereas stainless steel inner pots can withstand dishwasher cycles and high-temperature cleaning without damage. Choosing stainless steel can reduce long-term maintenance efforts, but may require more elbow grease to remove stubborn food residues compared to the easy-release properties of nonstick coatings.

Cost Comparison: Which Inner Pot Coating Is More Economical?

Nonstick inner pots generally require less time and effort for cleaning, reducing soap and water usage, which lowers overall maintenance costs compared to stainless steel pots. While stainless steel coatings tend to be more durable and resistant to scratching or peeling, they often require specialized cleaners and more intensive scrubbing, potentially increasing cleaning expenses over time. Considering initial investment and ongoing cleaning supplies, nonstick coatings present a more economical choice for daily use in pressure cooker maintenance.

Final Verdict: Best Pressure Cooker Inner Pot for Easy Cleaning

Nonstick coating on pressure cooker inner pots offers easy cleaning with food release properties that minimize scrubbing, making it ideal for quick maintenance. Stainless steel inner pots provide durability and resistance to scratching but may require more effort to clean due to food sticking. For effortless cleaning, nonstick-coated inner pots are the best choice, while stainless steel is preferred for long-term durability and a scratch-resistant surface.

Inner Pot Nonstick Coating vs Stainless Steel Coating for Pressure Cooker Cleaning Infographic

productvia.com

productvia.com