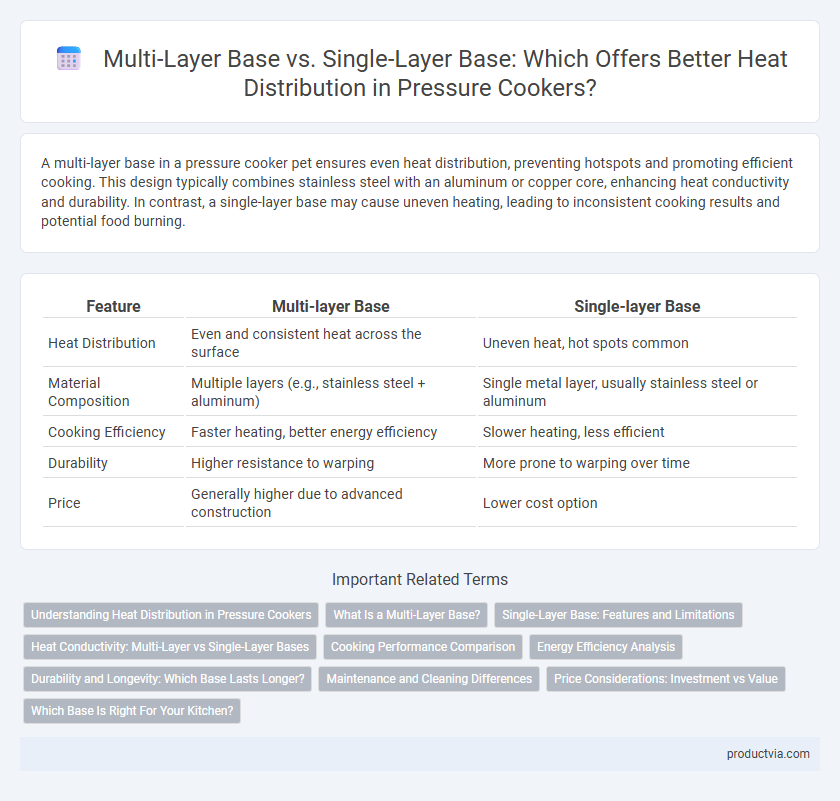

A multi-layer base in a pressure cooker pet ensures even heat distribution, preventing hotspots and promoting efficient cooking. This design typically combines stainless steel with an aluminum or copper core, enhancing heat conductivity and durability. In contrast, a single-layer base may cause uneven heating, leading to inconsistent cooking results and potential food burning.

Table of Comparison

| Feature | Multi-layer Base | Single-layer Base |

|---|---|---|

| Heat Distribution | Even and consistent heat across the surface | Uneven heat, hot spots common |

| Material Composition | Multiple layers (e.g., stainless steel + aluminum) | Single metal layer, usually stainless steel or aluminum |

| Cooking Efficiency | Faster heating, better energy efficiency | Slower heating, less efficient |

| Durability | Higher resistance to warping | More prone to warping over time |

| Price | Generally higher due to advanced construction | Lower cost option |

Understanding Heat Distribution in Pressure Cookers

Multi-layer bases in pressure cookers enhance heat distribution by combining aluminum and stainless steel layers, promoting even heat conduction and minimizing hot spots compared to single-layer bases. This design ensures faster cooking times and consistent temperature control, improving energy efficiency and food quality. Single-layer bases often cause uneven heating, leading to potential burning or undercooked areas, especially on induction cooktops.

What Is a Multi-Layer Base?

A multi-layer base in a pressure cooker typically consists of several layers of metal, such as stainless steel and aluminum, fused together to enhance heat distribution and retention. This design ensures even cooking by preventing hot spots and allowing heat to spread uniformly across the surface. Compared to a single-layer base, a multi-layer base improves energy efficiency and reduces the risk of food burning or sticking.

Single-Layer Base: Features and Limitations

A single-layer base in pressure cookers typically consists of a single metal type, such as stainless steel or aluminum, which limits its ability to distribute heat evenly across the cooking surface. This can result in hot spots and uneven cooking, requiring closer monitoring to prevent food from burning or sticking. While single-layer bases are generally more affordable, their heat retention and conduction capabilities are inferior compared to multi-layer bases, affecting overall cooking performance.

Heat Conductivity: Multi-Layer vs Single-Layer Bases

Multi-layer bases in pressure cookers feature a combination of metals like aluminum and stainless steel, enhancing heat conductivity and providing even heat distribution across the cooking surface. Single-layer bases, typically made from one metal, often struggle with uneven heat transfer, leading to hotspots and inconsistent cooking results. The superior heat conductivity of multi-layer bases ensures faster cooking times and improved energy efficiency compared to single-layer alternatives.

Cooking Performance Comparison

Multi-layer bases in pressure cookers provide superior heat distribution by combining materials such as stainless steel and aluminum, ensuring even cooking and preventing hot spots. Single-layer bases, typically made of only stainless steel, often result in uneven heat spread, leading to inconsistent cooking performance. The enhanced thermal conductivity of multi-layer bases significantly improves pressure buildup and energy efficiency during cooking.

Energy Efficiency Analysis

A multi-layer base in pressure cookers significantly enhances heat distribution by combining materials such as aluminum and stainless steel, leading to faster and more even cooking. This improved thermal conduction reduces energy consumption, as heat is retained and spread uniformly, minimizing hot spots and preventing food from burning. In contrast, single-layer bases often result in uneven heat distribution, causing longer cooking times and higher energy usage due to inefficient heat transfer.

Durability and Longevity: Which Base Lasts Longer?

Multi-layer bases in pressure cookers offer superior heat distribution and enhanced durability due to the combination of metals like aluminum and stainless steel, which resist warping and corrosion over time. Single-layer bases, typically made from a single metal, tend to heat unevenly and are more prone to damage, reducing their lifespan. Pressure cookers with multi-layer bases generally last longer, maintaining performance and structural integrity through extensive use.

Maintenance and Cleaning Differences

Multi-layer bases in pressure cookers feature several bonded layers of metal, enhancing even heat distribution and reducing hotspots, which minimizes food residue buildup and simplifies cleaning. Single-layer bases, often made from a single metal type, can cause uneven heating, resulting in more frequent stubborn food deposits that require intensive scrubbing during maintenance. Multi-layer bases typically resist warping and discoloration better over time, decreasing the frequency of deep cleaning compared to single-layer designs.

Price Considerations: Investment vs Value

A multi-layer base pressure cooker offers superior heat distribution due to its combination of metals like aluminum and stainless steel, resulting in consistent cooking and energy efficiency, which justifies its higher initial cost. Single-layer base models, often made of aluminum alone, come at a lower price but may cause uneven heating and increased risk of food burning, potentially leading to higher long-term energy expenses and reduced durability. Investing in a multi-layer base pressure cooker ensures better value through enhanced cooking performance, longevity, and energy savings, making it a cost-effective choice despite the upfront price difference.

Which Base Is Right For Your Kitchen?

A multi-layer base in pressure cookers offers superior heat distribution by combining different metals, such as aluminum and stainless steel, ensuring even cooking and preventing hot spots. Single-layer bases, typically made of stainless steel alone, may result in uneven heat transfer and longer cooking times, making them less efficient for recipes requiring precise temperature control. Choosing the right base depends on your cooking style; multi-layer bases are ideal for frequent, diverse cooking, while single-layer bases suit basic, occasional use.

Multi-layer base vs Single-layer base for heat distribution Infographic

productvia.com

productvia.com