Pressure cookers with an inner pot coating provide enhanced non-stick properties, making food release easier and cleaning more convenient, while also offering protection against rust and corrosion. In contrast, pressure cookers without coating require more careful maintenance to prevent sticking and potential damage, but some users prefer them for durability and avoiding chemical coatings. Choosing between coated and uncoated inner pots depends on personal preference for ease of use versus potential longevity and natural material benefits.

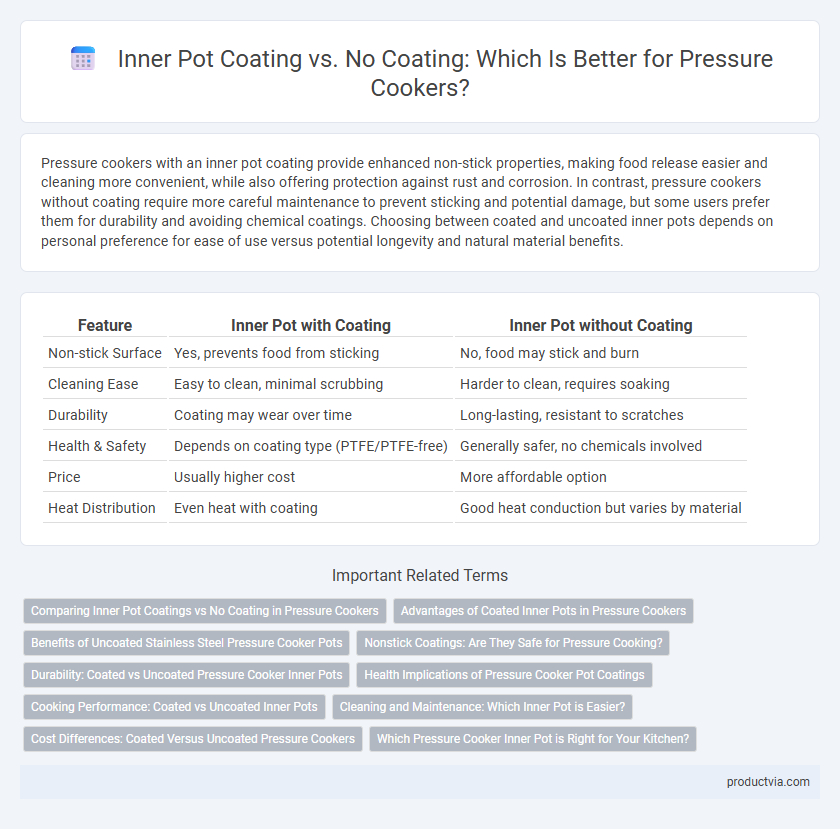

Table of Comparison

| Feature | Inner Pot with Coating | Inner Pot without Coating |

|---|---|---|

| Non-stick Surface | Yes, prevents food from sticking | No, food may stick and burn |

| Cleaning Ease | Easy to clean, minimal scrubbing | Harder to clean, requires soaking |

| Durability | Coating may wear over time | Long-lasting, resistant to scratches |

| Health & Safety | Depends on coating type (PTFE/PTFE-free) | Generally safer, no chemicals involved |

| Price | Usually higher cost | More affordable option |

| Heat Distribution | Even heat with coating | Good heat conduction but varies by material |

Comparing Inner Pot Coatings vs No Coating in Pressure Cookers

Pressure cookers with inner pot coatings, such as non-stick or ceramic layers, offer easier cleaning and reduced food sticking compared to uncoated stainless steel pots, enhancing cooking convenience and durability. However, pots without coatings often provide superior heat resistance and longevity without the risk of coating degradation or chemical leaching under high temperatures. Choosing between coated and uncoated inner pots depends on balancing ease of maintenance with long-term durability and safety preferences.

Advantages of Coated Inner Pots in Pressure Cookers

Coated inner pots in pressure cookers offer enhanced non-stick properties that simplify cooking and cleaning by preventing food from sticking and burning. These coatings, often made from materials like ceramic or Teflon, promote even heat distribution, improving cooking efficiency and preserving food texture. Moreover, coated pots reduce the need for excessive oil or butter, supporting healthier meal preparation and extending the longevity of the inner pot by protecting against scratches and corrosion.

Benefits of Uncoated Stainless Steel Pressure Cooker Pots

Uncoated stainless steel pressure cooker pots offer superior durability and resistance to scratching compared to coated alternatives, ensuring a longer lifespan without peeling or chipping. They provide a non-reactive cooking surface, preserving the taste and nutritional value of acidic or alkaline foods. Cleaning is simplified, as uncoated pots withstand aggressive scrubbing and high-temperature washing without damage.

Nonstick Coatings: Are They Safe for Pressure Cooking?

Nonstick coatings in pressure cookers, typically made from PTFE or ceramic materials, provide easy food release and simpler cleaning but may pose health concerns if overheated beyond manufacturer guidelines. Pressure cookers operate at high temperatures and pressure, so using an inner pot without coating eliminates risks of chemical leaching and coating degradation. Opting for stainless steel or uncoated aluminum inner pots enhances durability and safety, ensuring optimal cooking performance without the potential hazards of nonstick materials.

Durability: Coated vs Uncoated Pressure Cooker Inner Pots

Uncoated pressure cooker inner pots are typically made from stainless steel, offering superior durability and resistance to scratches, dents, and high heat compared to coated pots. Coated inner pots often feature non-stick layers that can degrade over time, leading to peeling and reduced lifespan. Choosing uncoated pots ensures longer-lasting performance, especially under frequent or high-temperature cooking conditions.

Health Implications of Pressure Cooker Pot Coatings

Pressure cooker inner pots with non-stick coatings often contain substances like PTFE or ceramic, which can degrade under high temperatures and potentially release harmful chemicals, raising health concerns. Uncoated stainless steel or aluminum pots avoid such risks by offering a durable, inert cooking surface that resists scratching and does not leach chemicals during cooking. Choosing an uncoated inner pot reduces exposure to toxic residues and contributes to safer food preparation in pressure cookers.

Cooking Performance: Coated vs Uncoated Inner Pots

Coated inner pots in pressure cookers offer non-stick properties that enhance cooking performance by preventing food from sticking and facilitating easier cleanup, which can preserve the integrity of delicate dishes. Uncoated stainless steel or aluminum pots provide superior durability and heat retention, promoting even heat distribution for consistent cooking results, especially in high-heat recipes. Choosing between coated and uncoated inner pots depends on balancing the convenience of non-stick surfaces with the long-term resilience and heat efficiency of bare metal materials.

Cleaning and Maintenance: Which Inner Pot is Easier?

Inner pots with non-stick coatings significantly simplify cleaning by preventing food from sticking, reducing scrubbing time and effort. Uncoated inner pots require thorough soaking and scrubbing to remove stubborn residues but offer durability without the risk of coating damage. Maintenance for coated pots involves careful use of non-abrasive utensils and cleaning tools, while uncoated pots can withstand harsher cleaning methods and frequent use.

Cost Differences: Coated Versus Uncoated Pressure Cookers

Pressure cookers with coated inner pots, typically featuring non-stick surfaces like Teflon or ceramic, are generally more expensive than uncoated stainless steel models due to higher manufacturing costs and added material benefits. Uncoated inner pots offer greater durability and resistance to scratching or chipping, often resulting in longer lifespan and lower replacement expenses despite a lower upfront price. Consumers choosing between coated and uncoated pressure cookers should balance initial cost against maintenance needs and cooking preferences to determine the most cost-effective option.

Which Pressure Cooker Inner Pot is Right for Your Kitchen?

Pressure cooker inner pots with non-stick coatings offer easy cleaning and prevent food from sticking, ideal for low-fat cooking and delicate recipes. Stainless steel pots without coating provide durability, resist scratches, and allow high-heat searing, making them suitable for heavy-duty use and browning meats. Choosing between coated and uncoated inner pots depends on your cooking style, maintenance preferences, and the types of dishes you frequently prepare.

Inner pot coating vs No coating for pressure cookers Infographic

productvia.com

productvia.com