Inverter compressors in refrigerators operate at variable speeds, significantly reducing noise levels compared to conventional compressors that run at fixed speeds and produce louder, more frequent sounds. This advanced technology ensures quieter operation by adjusting cooling capacity based on demand, resulting in less vibration and noise. Pet owners benefit from inverter compressors as they create a calmer environment, minimizing disturbances for sensitive animals.

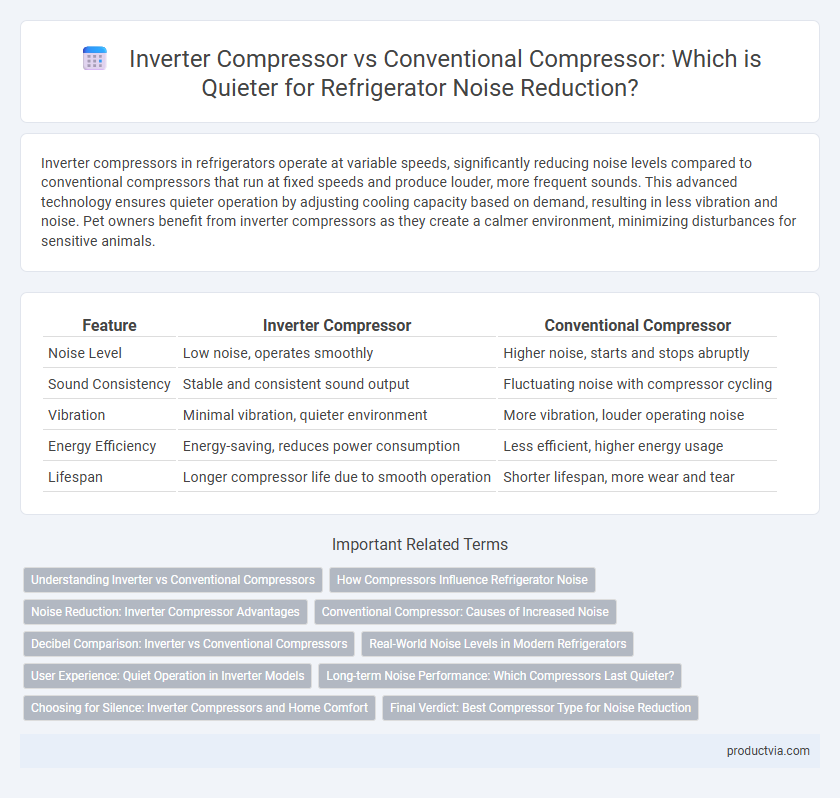

Table of Comparison

| Feature | Inverter Compressor | Conventional Compressor |

|---|---|---|

| Noise Level | Low noise, operates smoothly | Higher noise, starts and stops abruptly |

| Sound Consistency | Stable and consistent sound output | Fluctuating noise with compressor cycling |

| Vibration | Minimal vibration, quieter environment | More vibration, louder operating noise |

| Energy Efficiency | Energy-saving, reduces power consumption | Less efficient, higher energy usage |

| Lifespan | Longer compressor life due to smooth operation | Shorter lifespan, more wear and tear |

Understanding Inverter vs Conventional Compressors

Inverter compressors in refrigerators operate at variable speeds, allowing them to adjust cooling power precisely and reduce noise levels significantly compared to conventional compressors, which run at a fixed speed and often produce louder, more disruptive sounds. The continuous modulation by inverter technology minimizes the frequent start-stop cycles typical of conventional compressors, resulting in smoother and quieter operation. This noise reduction enhances the overall user experience by creating a quieter kitchen environment and reducing mechanical wear on the compressor.

How Compressors Influence Refrigerator Noise

Inverter compressors significantly reduce refrigerator noise by operating at variable speeds, allowing for smoother and quieter performance compared to the constant on/off cycling of conventional compressors. This continuous adjustment minimizes vibrations and mechanical strain, leading to less operational noise. Conventional compressors produce louder sounds due to frequent starting and stopping, which generates more noise and vibration inside the refrigerator.

Noise Reduction: Inverter Compressor Advantages

Inverter compressors significantly reduce noise levels compared to conventional compressors by operating at variable speeds, allowing for smoother and quieter performance. Their ability to adjust power based on cooling demand minimizes sudden motor starts and stops, which are common sources of loud noise in conventional systems. This technology ensures a quieter refrigerator environment, enhancing user comfort and reducing ambient noise in homes.

Conventional Compressor: Causes of Increased Noise

Conventional compressors generate increased noise due to their start-stop operation, causing vibrations and sudden mechanical movements. The lack of variable speed control results in frequent compressor cycling, which amplifies sound levels and creates inconsistent noise patterns. Additionally, older components and less advanced insulation contribute to higher noise emissions compared to inverter compressors.

Decibel Comparison: Inverter vs Conventional Compressors

Inverter compressors typically operate at noise levels ranging from 38 to 45 decibels, significantly quieter than conventional compressors, which often produce noise between 45 and 60 decibels. The variable speed technology in inverter compressors allows for smoother and less frequent motor cycles, reducing overall sound output. This decibel difference makes inverter compressors ideal for noise-sensitive environments, enhancing kitchen comfort by minimizing operational noise.

Real-World Noise Levels in Modern Refrigerators

Inverter compressors in modern refrigerators operate at variable speeds, significantly reducing noise levels compared to conventional compressors that run at fixed speeds. Real-world measurements show inverter compressors produce sound levels as low as 38-42 decibels, while conventional compressors typically generate 45-50 decibels during operation. This reduction in noise enhances user comfort, especially in open-plan kitchens and small living spaces.

User Experience: Quiet Operation in Inverter Models

Inverter compressors in refrigerators deliver significantly quieter operation compared to conventional compressors by adjusting their speed according to cooling demand, minimizing noise fluctuations and vibrations. This results in a more peaceful kitchen environment, enhancing user comfort during daily activities. The consistent, low-noise performance of inverter models reduces auditory distractions, making them ideal for open-concept homes and noise-sensitive settings.

Long-term Noise Performance: Which Compressors Last Quieter?

Inverter compressors maintain lower noise levels over time due to variable speed operation that reduces mechanical stress and wear. Conventional compressors operate at fixed speeds, causing louder noise spikes and increased vibration as components degrade. Long-term noise performance significantly favors inverter compressors, providing quieter operation throughout the refrigerator's lifespan.

Choosing for Silence: Inverter Compressors and Home Comfort

Inverter compressors in refrigerators significantly reduce noise levels by adjusting their speed based on cooling demands, unlike conventional compressors that operate at a constant speed and generate louder sounds. This variable speed operation ensures a quieter environment, enhancing home comfort by minimizing disruptions during daily activities and sleep. Choosing an inverter compressor is ideal for households prioritizing silent appliances and improved energy efficiency.

Final Verdict: Best Compressor Type for Noise Reduction

Inverter compressors operate at variable speeds, significantly reducing noise levels compared to conventional compressors that run at fixed speeds and generate more abrupt sounds. The ability of inverter compressors to adjust their motor speed ensures smoother and quieter operation, making them the best choice for noise-sensitive environments. Therefore, for optimal noise reduction, inverter compressors outperform conventional compressors in refrigerator applications.

Inverter compressor vs Conventional compressor for noise reduction Infographic

productvia.com

productvia.com