Inverter compressors offer variable speed control, resulting in improved energy efficiency and quieter operation compared to reciprocating compressors that run at a fixed speed. Reciprocating compressors tend to have higher energy consumption and more noise due to their start-stop operation. Choosing an inverter compressor for your refrigerator motor can lead to longer lifespan and better temperature stability.

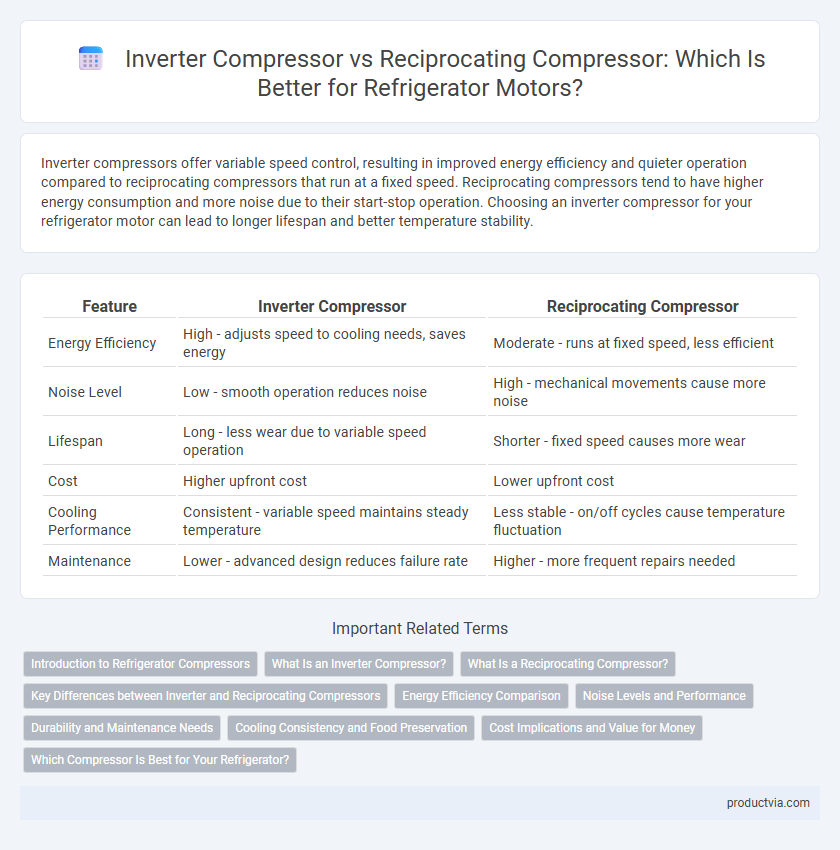

Table of Comparison

| Feature | Inverter Compressor | Reciprocating Compressor |

|---|---|---|

| Energy Efficiency | High - adjusts speed to cooling needs, saves energy | Moderate - runs at fixed speed, less efficient |

| Noise Level | Low - smooth operation reduces noise | High - mechanical movements cause more noise |

| Lifespan | Long - less wear due to variable speed operation | Shorter - fixed speed causes more wear |

| Cost | Higher upfront cost | Lower upfront cost |

| Cooling Performance | Consistent - variable speed maintains steady temperature | Less stable - on/off cycles cause temperature fluctuation |

| Maintenance | Lower - advanced design reduces failure rate | Higher - more frequent repairs needed |

Introduction to Refrigerator Compressors

Refrigerator compressors, essential for cooling performance, come primarily in inverter and reciprocating types, each with distinct operational mechanisms and efficiency levels. Inverter compressors adjust speed based on cooling demand, offering enhanced energy efficiency and quieter operation compared to the traditional reciprocating compressors, which use a fixed-speed piston movement. Understanding these differences is crucial for selecting refrigerators that optimize energy use and maintain consistent temperature control.

What Is an Inverter Compressor?

An inverter compressor in refrigerator motors is a technology that adjusts the compressor speed based on cooling demand, optimizing energy consumption and maintaining consistent temperature levels. Unlike traditional reciprocating compressors that operate at fixed speeds, inverter compressors provide variable speed control, resulting in quieter operation and enhanced efficiency. This precise modulation reduces wear and tear on components, extending the refrigerator's lifespan while significantly lowering electricity bills.

What Is a Reciprocating Compressor?

A reciprocating compressor in refrigerators operates using a piston that compresses refrigerant gas inside a cylinder, providing efficient cooling through repeated up-and-down motion. This type of compressor is known for its durability and straightforward mechanical design, making it a common choice in many traditional refrigerator models. Despite being less energy-efficient than inverter compressors, reciprocating compressors deliver consistent performance, especially in environments requiring stable cooling cycles.

Key Differences between Inverter and Reciprocating Compressors

Inverter compressors in refrigerators offer variable speed operation that adjusts cooling output based on demand, resulting in improved energy efficiency and quieter performance compared to reciprocating compressors, which operate at a fixed speed with a start-stop mechanism. Reciprocating compressors use pistons to compress refrigerant, causing more vibration and noise, while inverter compressors use a brushless DC motor that reduces wear and enhances durability. The precise speed control of inverter compressors provides better temperature stability and faster cooling than the conventional reciprocating design, making them ideal for modern energy-saving appliances.

Energy Efficiency Comparison

Inverter compressors in refrigerators adjust motor speed to match cooling demand, significantly reducing energy consumption compared to reciprocating compressors that operate at a fixed speed. Studies show inverter compressors can achieve up to 30-50% higher energy efficiency, leading to substantial electricity cost savings and a lower environmental footprint. This dynamic speed control also enhances temperature stability and compressor lifespan, making inverter technology the preferred choice for energy-conscious consumers.

Noise Levels and Performance

Inverter compressors in refrigerators operate with variable speeds, resulting in significantly lower noise levels and enhanced energy efficiency compared to reciprocating compressors, which run at a fixed speed and generate more noise due to piston movement. The inverter technology provides smoother temperature control and longer motor lifespan by reducing mechanical stress, while reciprocating compressors, despite their higher noise output, tend to have a lower initial cost. Choosing between the two depends on balancing quieter operation and energy savings against budget constraints and durability requirements.

Durability and Maintenance Needs

Inverter compressors for refrigerators offer enhanced durability due to their variable speed operation, which reduces wear and tear on components by avoiding constant start-stop cycles typical of reciprocating compressors. Reciprocating compressors experience higher mechanical strain and frequent maintenance needs because their fixed-speed operation causes more vibration and stress on motor parts. Consequently, inverter compressors require less frequent maintenance and provide longer operational lifespan, making them ideal for energy-efficient, low-maintenance refrigeration solutions.

Cooling Consistency and Food Preservation

Inverter compressors maintain precise motor speed control, providing consistent cooling that stabilizes internal temperatures and extends food freshness by preventing temperature fluctuations. Reciprocating compressors operate on fixed speeds, causing periodic temperature spikes that may accelerate food spoilage due to inconsistent cooling. Superior energy efficiency and quieter operation of inverter compressors contribute to optimized food preservation in modern refrigerators.

Cost Implications and Value for Money

Inverter compressors for refrigerator motors typically have a higher upfront cost compared to reciprocating compressors but offer significant energy savings and quieter operation, enhancing long-term value for money. Reciprocating compressors are more affordable initially but tend to consume more electricity and experience greater wear, leading to higher maintenance expenses over time. Investing in an inverter compressor is cost-effective for energy efficiency and durability, while reciprocating compressors suit budget-conscious buyers prioritizing low initial costs.

Which Compressor Is Best for Your Refrigerator?

Inverter compressors offer precise speed control and energy efficiency, reducing electricity consumption by up to 30% compared to reciprocating compressors, which operate at fixed speeds and tend to be noisier. Reciprocating compressors are generally more affordable and simpler in design but may cause temperature fluctuations due to their on-off cycling. Choosing the best compressor depends on priorities such as energy savings, noise levels, budget, and desired temperature stability in your refrigerator.

Inverter Compressor vs Reciprocating Compressor for Refrigerator Motor Infographic

productvia.com

productvia.com