Ceramic coating on sandwich maker plates offers superior heat distribution and durability compared to Teflon coating, which may wear off over time and release harmful particles when scratched. Ceramic surfaces are generally more resistant to high temperatures and easier to clean without the risk of flaking. Choosing ceramic coating enhances non-stick performance while ensuring a safer and longer-lasting cooking experience.

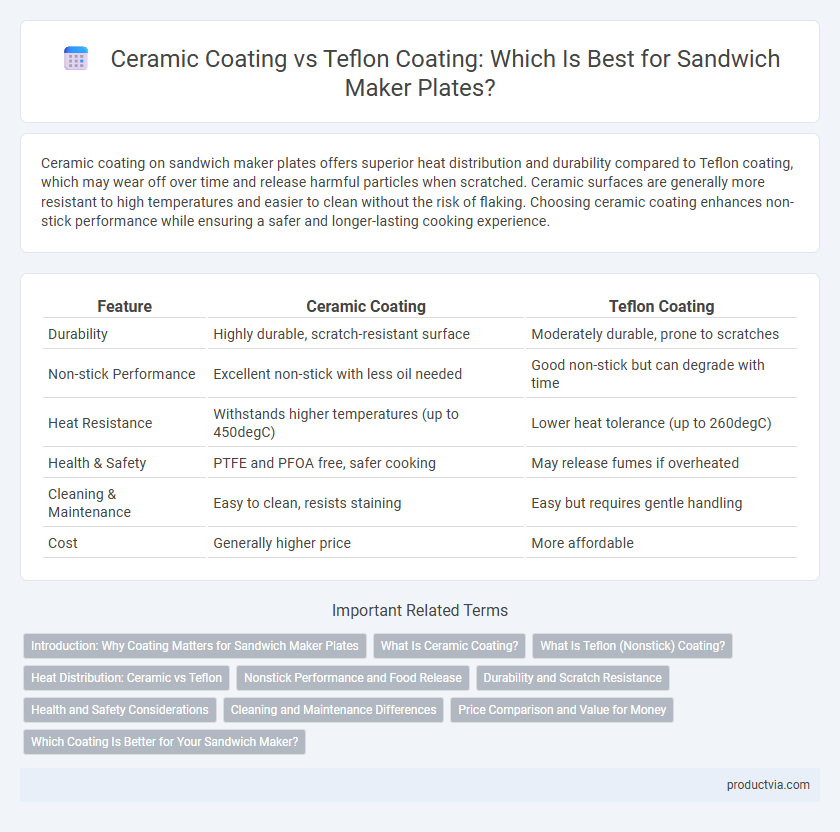

Table of Comparison

| Feature | Ceramic Coating | Teflon Coating |

|---|---|---|

| Durability | Highly durable, scratch-resistant surface | Moderately durable, prone to scratches |

| Non-stick Performance | Excellent non-stick with less oil needed | Good non-stick but can degrade with time |

| Heat Resistance | Withstands higher temperatures (up to 450degC) | Lower heat tolerance (up to 260degC) |

| Health & Safety | PTFE and PFOA free, safer cooking | May release fumes if overheated |

| Cleaning & Maintenance | Easy to clean, resists staining | Easy but requires gentle handling |

| Cost | Generally higher price | More affordable |

Introduction: Why Coating Matters for Sandwich Maker Plates

Coating on sandwich maker plates directly impacts cooking performance, durability, and ease of cleaning, making it a critical factor in product quality. Ceramic coatings offer high heat resistance and scratch durability, promoting even cooking and long-lasting use without releasing harmful fumes. Teflon coatings provide excellent non-stick properties for effortless food release and cleaning but may degrade faster under high temperatures or abrasive utensils.

What Is Ceramic Coating?

Ceramic coating on sandwich maker plates is a non-stick layer made from inorganic mineral compounds, offering superior heat distribution and durability compared to traditional coatings. It resists high temperatures and scratches while being free from harmful chemicals like PTFE and PFOA found in Teflon coatings. This makes ceramic-coated plates a safer, eco-friendly choice with easy cleaning and longer-lasting performance.

What Is Teflon (Nonstick) Coating?

Teflon coating, a type of nonstick surface made from polytetrafluoroethylene (PTFE), is commonly used on sandwich maker plates to prevent food from sticking and facilitate easy cleaning. This synthetic fluoropolymer offers excellent heat resistance and durability, ensuring even cooking without the need for excessive oil or butter. While highly effective, Teflon coatings should be used with non-metal utensils to avoid scratching and degradation of the nonstick properties.

Heat Distribution: Ceramic vs Teflon

Ceramic-coated sandwich maker plates offer superior heat distribution due to their ability to maintain even temperatures across the surface, reducing hotspots and ensuring consistent cooking. Teflon-coated plates provide decent heat distribution but can experience uneven heating, leading to potential burning or undercooked areas. The ceramic coating's enhanced thermal conductivity makes it ideal for achieving perfectly toasted sandwiches with uniform browning.

Nonstick Performance and Food Release

Ceramic coating on sandwich maker plates provides superior nonstick performance with a natural, chemical-free surface that resists scratching and ensures easy food release without the need for excessive oil. Teflon coating offers excellent initial nonstick properties but tends to degrade over time, potentially leading to reduced food release efficiency and increased risk of flaking. Both coatings enhance cooking convenience, but ceramic plates generally maintain consistent nonstick quality and durability, making them a preferred choice for long-term use.

Durability and Scratch Resistance

Ceramic coating on sandwich maker plates offers superior durability and high scratch resistance compared to Teflon coating, making it more suitable for frequent use and metal utensils. Teflon coatings tend to degrade faster under high heat and are more prone to scratches, which can reduce their non-stick effectiveness over time. Users seeking long-lasting performance often prefer ceramic coating for its resistance to wear and ability to maintain a smooth, non-stick surface.

Health and Safety Considerations

Ceramic coating on sandwich maker plates offers a non-toxic, chemical-free surface that reduces the risk of harmful fumes and potential health hazards compared to Teflon's polytetrafluoroethylene (PTFE), which can release toxic compounds if overheated beyond 260degC (500degF). Ceramic coatings are more resistant to scratches and peeling, minimizing contamination risks from metal flakes that can occur with deteriorating Teflon surfaces. Choosing ceramic-coated sandwich maker plates enhances food safety and promotes healthier cooking by eliminating exposure to potentially carcinogenic substances associated with degraded non-stick coatings.

Cleaning and Maintenance Differences

Ceramic coating on sandwich maker plates offers superior non-stick properties that resist scratches and facilitate easier cleaning with just a soft cloth, while Teflon coating requires more careful handling to avoid peeling and often needs gentle, non-abrasive cleaning tools. Ceramic surfaces typically withstand higher temperatures and maintain their coating durability longer, reducing the frequency of re-coating or replacement compared to Teflon. Regular maintenance of ceramic-coated plates involves simple wiping and occasional use of mild detergents, whereas Teflon-coated plates demand cautious cleaning routines to preserve the integrity of the non-stick layer and prevent toxic compound exposure from damaged surfaces.

Price Comparison and Value for Money

Ceramic coating sandwich maker plates generally cost more upfront than Teflon-coated options, reflecting their durability and non-toxic properties. Teflon-coated plates tend to be more affordable but may wear out faster, requiring replacement sooner. For value for money, ceramic coatings offer longer lifespan and safer cooking, making them a better investment despite the higher initial price.

Which Coating Is Better for Your Sandwich Maker?

Ceramic coating offers superior heat resistance and scratch durability compared to Teflon coating, making it ideal for sandwich makers used frequently or with metal utensils. Teflon coating provides excellent non-stick performance but tends to degrade faster and may release harmful fumes if overheated. Choosing ceramic coating ensures a longer-lasting, safer surface while Teflon excels in effortless food release and easy cleaning for occasional use.

Ceramic coating vs Teflon coating for sandwich maker plates Infographic

productvia.com

productvia.com