Non-stick coating on sandwich maker plates offers easy food release and quick cleaning, making it ideal for everyday use. Ceramic coating provides a more eco-friendly, durable surface that resists scratches and higher temperatures without toxic chemicals. Choosing between the two depends on whether you prioritize convenience and affordability or longevity and health-conscious materials.

Table of Comparison

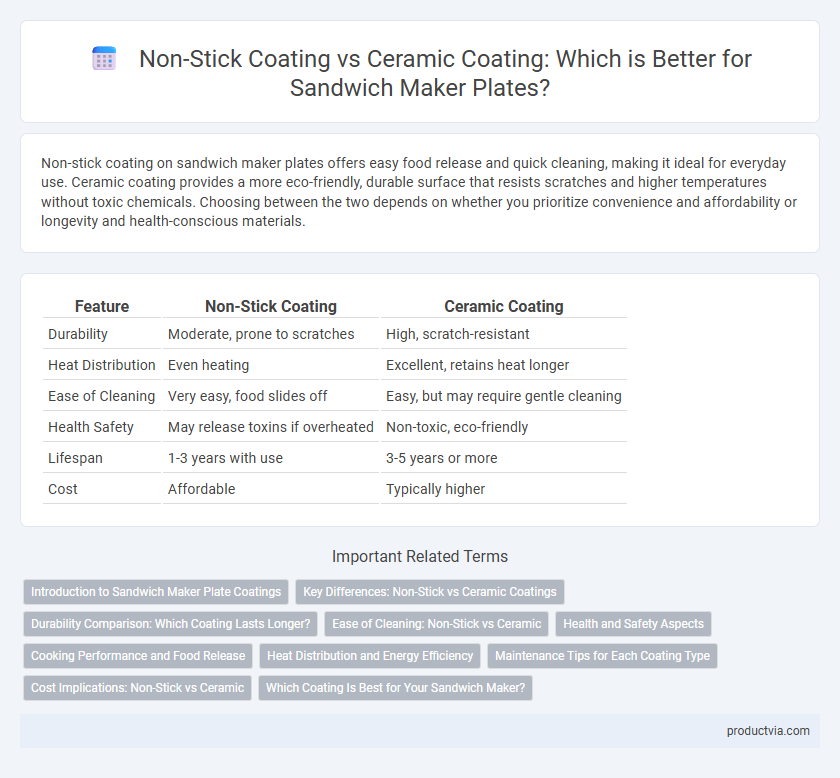

| Feature | Non-Stick Coating | Ceramic Coating |

|---|---|---|

| Durability | Moderate, prone to scratches | High, scratch-resistant |

| Heat Distribution | Even heating | Excellent, retains heat longer |

| Ease of Cleaning | Very easy, food slides off | Easy, but may require gentle cleaning |

| Health Safety | May release toxins if overheated | Non-toxic, eco-friendly |

| Lifespan | 1-3 years with use | 3-5 years or more |

| Cost | Affordable | Typically higher |

Introduction to Sandwich Maker Plate Coatings

Sandwich maker plates commonly feature non-stick or ceramic coatings, each enhancing cooking efficiency and ease of cleaning. Non-stick coatings, typically made from polytetrafluoroethylene (PTFE), provide excellent food release and require minimal oil, reducing calorie intake. Ceramic coatings offer a chemical-free alternative, with high heat resistance and durability, appealing to health-conscious users seeking eco-friendly kitchen appliances.

Key Differences: Non-Stick vs Ceramic Coatings

Non-stick coatings on sandwich maker plates provide excellent food release and easy cleaning but may wear off over time and can be sensitive to metal utensils. Ceramic coatings offer superior heat resistance and durability, maintaining non-stick properties longer and being free of harmful chemicals like PTFE and PFOA. Choosing between non-stick and ceramic depends on preferences for longevity, safety, and maintenance requirements.

Durability Comparison: Which Coating Lasts Longer?

Non-stick coatings on sandwich maker plates typically last between 1 to 3 years with regular use, but they can degrade faster if exposed to metal utensils or abrasive cleaning. Ceramic coatings offer superior durability, resisting scratches and high temperatures more effectively, often maintaining their non-stick properties for 3 to 5 years or longer. Users seeking longer-lasting sandwich makers should consider ceramic-coated plates for enhanced wear resistance and consistent performance.

Ease of Cleaning: Non-Stick vs Ceramic

Non-stick coating on sandwich maker plates offers superior ease of cleaning due to its smooth surface that prevents food from adhering, requiring minimal effort to wipe off residue. Ceramic coating provides a durable, scratch-resistant layer that can handle higher temperatures but may require more thorough cleaning to remove stubborn, stuck-on food particles. Both coatings reduce the need for excessive scrubbing, but non-stick surfaces generally offer quicker and more convenient cleanup after use.

Health and Safety Aspects

Non-stick coatings in sandwich makers typically use polytetrafluoroethylene (PTFE), which is safe at cooking temperatures but may release harmful fumes if overheated, posing health risks. Ceramic coatings are free from PTFE and PFOA, offering a non-toxic surface that withstands higher temperatures without releasing harmful emissions, enhancing safety during cooking. Both coatings require proper maintenance to avoid degradation, but ceramic coatings generally provide a healthier, eco-friendlier option for long-term use.

Cooking Performance and Food Release

Non-stick coating on sandwich maker plates offers superior food release, preventing sticking and ensuring easy cleaning, while ceramic coatings provide even heat distribution, enhancing consistent cooking performance. Ceramic coatings are more scratch-resistant and durable, maintaining effective cooking surfaces over time without compromising non-stick benefits. Choosing between these coatings depends on whether ease of cleaning or long-term durability with uniform heat is the priority for optimal sandwich preparation.

Heat Distribution and Energy Efficiency

Non-stick coating on sandwich maker plates provides even heat distribution, ensuring sandwiches cook uniformly while minimizing energy consumption due to its quick heating properties. Ceramic coating offers superior heat retention and distributes heat more consistently, which enhances energy efficiency by maintaining temperature longer and reducing the need for constant power. Both coatings optimize cooking performance, but ceramic's durability and sustained heat may lead to better long-term energy savings compared to traditional non-stick surfaces.

Maintenance Tips for Each Coating Type

Non-stick coating on sandwich maker plates requires gentle cleaning with a soft sponge and mild detergent to prevent scratches and preserve the surface longevity, avoiding abrasive scrubbers or metallic utensils. Ceramic coatings benefit from immediate cleaning after use to remove food residues, using a soft cloth or sponge and non-abrasive cleaners, ensuring the coating's natural non-stick properties remain effective. Regular maintenance for both types includes drying plates thoroughly before storage to prevent rust or damage, extending the sandwich maker's operational life.

Cost Implications: Non-Stick vs Ceramic

Non-stick coatings on sandwich maker plates are generally more affordable, offering cost-effective durability suitable for everyday use. Ceramic coatings tend to be pricier initially but provide longer-lasting resistance to scratches and high temperatures, potentially reducing replacement costs over time. Choosing between non-stick and ceramic involves balancing upfront expenditure with long-term maintenance expenses.

Which Coating Is Best for Your Sandwich Maker?

Non-stick coating offers superior stain resistance and easy food release, making cleanup quick and maintaining the sandwich maker's performance over time. Ceramic coating provides a chemical-free, eco-friendly surface that withstands higher temperatures and reduces the risk of scratching, ideal for users prioritizing health and durability. Choosing between non-stick and ceramic coatings depends on whether you value effortless maintenance and longevity or prefer a natural, heat-resistant option for your sandwich maker plates.

Non-stick coating vs Ceramic coating for sandwich maker plates Infographic

productvia.com

productvia.com