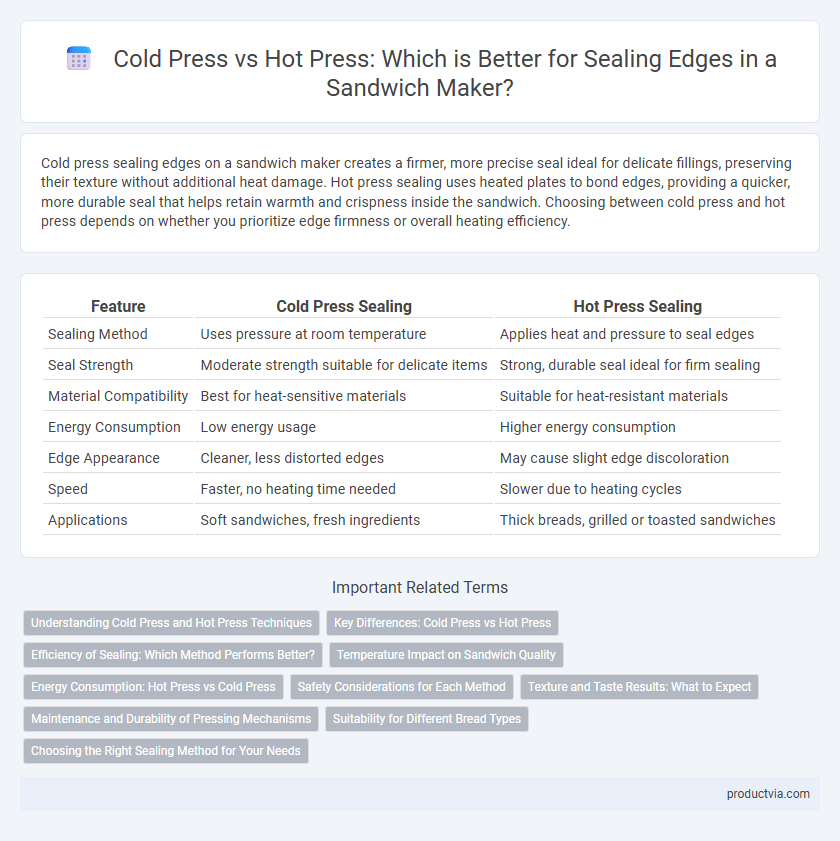

Cold press sealing edges on a sandwich maker creates a firmer, more precise seal ideal for delicate fillings, preserving their texture without additional heat damage. Hot press sealing uses heated plates to bond edges, providing a quicker, more durable seal that helps retain warmth and crispness inside the sandwich. Choosing between cold press and hot press depends on whether you prioritize edge firmness or overall heating efficiency.

Table of Comparison

| Feature | Cold Press Sealing | Hot Press Sealing |

|---|---|---|

| Sealing Method | Uses pressure at room temperature | Applies heat and pressure to seal edges |

| Seal Strength | Moderate strength suitable for delicate items | Strong, durable seal ideal for firm sealing |

| Material Compatibility | Best for heat-sensitive materials | Suitable for heat-resistant materials |

| Energy Consumption | Low energy usage | Higher energy consumption |

| Edge Appearance | Cleaner, less distorted edges | May cause slight edge discoloration |

| Speed | Faster, no heating time needed | Slower due to heating cycles |

| Applications | Soft sandwiches, fresh ingredients | Thick breads, grilled or toasted sandwiches |

Understanding Cold Press and Hot Press Techniques

Cold press sealing uses lower temperatures and high pressure to bond sandwich edges without melting the materials, preserving the texture and preventing warping. Hot press sealing applies heat and pressure to fuse edges, creating a stronger, airtight seal ideal for heat-sensitive fillings. Understanding these techniques helps select the best sealing method based on sandwich type and desired shelf life.

Key Differences: Cold Press vs Hot Press

Cold press sealing in sandwich makers relies on applying pressure at room temperature, resulting in a cleaner, less cooked edge ideal for fresh ingredients and delicate breads. Hot press sealing uses heated plates to fuse sandwich edges, creating a crispy, golden crust that enhances texture and extends shelf life. The choice between cold press and hot press depends on desired edge texture, sandwich composition, and cooking speed preferences.

Efficiency of Sealing: Which Method Performs Better?

Cold press sealing offers a gentler approach by applying pressure without heat, preserving the sandwich's texture but sometimes resulting in weaker edges prone to leaks. Hot press sealing uses heat combined with pressure, creating a stronger, more durable bond that enhances edge integrity and prevents fillings from escaping, thereby increasing overall efficiency. For optimal sealing performance in sandwich makers, hot press methods generally outperform cold press by providing consistent, reliable seals ideal for both home and commercial use.

Temperature Impact on Sandwich Quality

Cold press sealing in sandwich makers preserves ingredient freshness and texture by applying lower temperatures, preventing overcooking and sogginess. Hot press sealing uses elevated temperatures to create a crispy, golden crust while ensuring the edges are tightly sealed to avoid filling leakage. Temperature control directly impacts sandwich quality by balancing crust crispiness and ingredient integrity, enhancing overall flavor and mouthfeel.

Energy Consumption: Hot Press vs Cold Press

Hot press sealing edges consumes significantly more energy due to heating elements required to melt and bond materials, making it less efficient for energy-sensitive applications. Cold press sealing uses mechanical pressure without heat, resulting in lower energy consumption and a more sustainable sealing process. Choosing cold press methods can reduce operational costs and environmental impact while maintaining effective edge sealing.

Safety Considerations for Each Method

Cold press sealing uses lower temperatures, reducing the risk of burns and ensuring safer handling during sandwich maker operation. Hot press sealing employs high heat, which can effectively create airtight edges but requires caution to prevent accidents or damage to heat-sensitive ingredients. Selecting the appropriate sealing method balances safety concerns with the desired seal quality in sandwich preparation.

Texture and Taste Results: What to Expect

Cold press sealing in sandwich makers preserves the freshness of ingredients by applying gentle pressure that avoids compressing fillings, resulting in a lighter texture with distinct layers and more pronounced flavors. Hot press sealing uses heat and pressure to create a crispy, golden-brown crust that enhances the taste through caramelization and Maillard reactions, producing a warm, crunchy texture. Expect cold press sandwiches to deliver a fresher, moister bite, while hot press sandwiches offer a richer, toasted flavor profile with a satisfying crunch.

Maintenance and Durability of Pressing Mechanisms

Cold press sealing mechanisms typically require less maintenance due to the absence of heat elements, reducing the risk of wear and tear caused by thermal expansion. The durability of cold press systems is enhanced by fewer moving parts and reduced exposure to high temperatures, resulting in longer-lasting seals. However, hot press mechanisms, while prone to more frequent maintenance due to heat-induced stress, offer stronger, more reliable sealing but may experience faster degradation of components over time.

Suitability for Different Bread Types

Cold press sealing is ideal for delicate and soft bread varieties like brioche or sourdough, as it prevents crushing and preserves texture while ensuring a secure edge. Hot press sealing works best with firm and dense bread such as whole wheat or rye, offering a stronger seal by slightly toasting and compressing the edges for durability. Choosing the right press method enhances sandwich quality by matching sealing technique with bread texture and moisture content.

Choosing the Right Sealing Method for Your Needs

Cold press sealing preserves the texture and flavor of delicate sandwich ingredients by applying pressure without heat, ideal for fresh and crispy fillings. Hot press sealing fuses edges with heat, creating a strong, airtight seal that prevents leakage and enhances shelf life, particularly suitable for sandwiches with moist or gooey fillings. Selecting the right sealing method depends on the desired sandwich freshness, texture, and storage duration to ensure optimal taste and durability.

Cold press vs Hot press for sealing edges Infographic

productvia.com

productvia.com