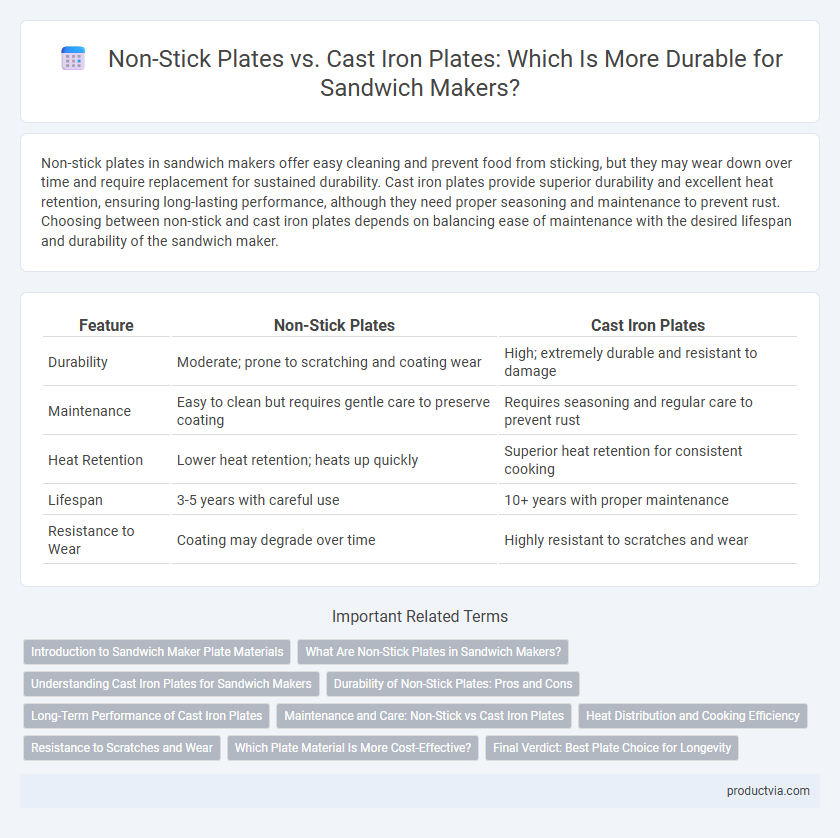

Non-stick plates in sandwich makers offer easy cleaning and prevent food from sticking, but they may wear down over time and require replacement for sustained durability. Cast iron plates provide superior durability and excellent heat retention, ensuring long-lasting performance, although they need proper seasoning and maintenance to prevent rust. Choosing between non-stick and cast iron plates depends on balancing ease of maintenance with the desired lifespan and durability of the sandwich maker.

Table of Comparison

| Feature | Non-Stick Plates | Cast Iron Plates |

|---|---|---|

| Durability | Moderate; prone to scratching and coating wear | High; extremely durable and resistant to damage |

| Maintenance | Easy to clean but requires gentle care to preserve coating | Requires seasoning and regular care to prevent rust |

| Heat Retention | Lower heat retention; heats up quickly | Superior heat retention for consistent cooking |

| Lifespan | 3-5 years with careful use | 10+ years with proper maintenance |

| Resistance to Wear | Coating may degrade over time | Highly resistant to scratches and wear |

Introduction to Sandwich Maker Plate Materials

Non-stick plates in sandwich makers offer easy food release and straightforward cleaning, making them popular for everyday use. Cast iron plates provide superior durability and heat retention, ensuring even cooking and longer lifespan despite requiring more maintenance. Choosing between non-stick and cast iron depends on balancing convenience with durability and cooking performance.

What Are Non-Stick Plates in Sandwich Makers?

Non-stick plates in sandwich makers are coated with a Teflon or ceramic layer that prevents food from sticking, allowing for easy cleaning and even cooking. These plates offer moderate durability but can wear down or chip with frequent use or abrasive cleaning tools. Cast iron plates, by contrast, provide superior durability and heat retention but require seasoning and more maintenance to prevent rust.

Understanding Cast Iron Plates for Sandwich Makers

Cast iron plates for sandwich makers offer exceptional durability due to their robust material composition, resisting warping and wear over long-term use. Unlike non-stick plates that may degrade or peel with frequent use, cast iron maintains consistent heat distribution and strengthens with seasoning over time. Understanding the superior lifespan and heat retention of cast iron plates can help users choose a sandwich maker that endures intensive daily use while delivering evenly toasted sandwiches.

Durability of Non-Stick Plates: Pros and Cons

Non-stick plates in sandwich makers offer excellent convenience due to their easy cleaning and reduced food sticking, but their durability can be compromised by frequent use, abrasive utensils, or improper cleaning methods. While these plates resist rusting and corrosion, the non-stick coating may wear off over time, leading to reduced effectiveness and potential scratching. Proper maintenance and gentle handling can extend their lifespan, but they generally don't match the rugged durability of cast iron plates.

Long-Term Performance of Cast Iron Plates

Cast iron plates in sandwich makers offer superior long-term durability compared to non-stick plates, resisting scratches and abrasions that typically degrade non-stick coatings over time. The robust construction of cast iron enables consistent heat retention and distribution, ensuring even toasting while maintaining structural integrity through years of frequent use. Regular seasoning of cast iron plates enhances their non-stick properties, extending the lifespan and performance well beyond that of traditional non-stick surfaces.

Maintenance and Care: Non-Stick vs Cast Iron Plates

Non-stick plates in sandwich makers require gentle cleaning with soft sponges and mild detergents to avoid damaging the coating, ensuring prolonged durability and easy maintenance. Cast iron plates demand regular seasoning and thorough drying after cleaning to prevent rust and maintain their longevity, offering robust durability but higher upkeep. Proper care for non-stick surfaces reduces peeling risks, while cast iron's maintenance ensures persistent non-stick characteristics and structural integrity over time.

Heat Distribution and Cooking Efficiency

Non-stick plates in sandwich makers offer superior heat distribution with an even cooking surface that minimizes hotspots, enhancing overall cooking efficiency and easy food release. Cast iron plates, while highly durable and excellent at retaining heat, often require longer preheating times and careful maintenance to prevent rusting but provide consistent heat essential for thorough sandwich toasting. Choosing between non-stick and cast iron depends on balancing quick heat responsiveness and effortless cleaning against long-term durability and robust heat retention.

Resistance to Scratches and Wear

Non-stick plates in sandwich makers offer excellent resistance to scratches and wear due to their smooth, coated surfaces that prevent food from sticking and reduce abrasion. Cast iron plates provide superior long-term durability and can endure heavy use without warping, but they are more prone to surface scratches and require regular seasoning to maintain their protective layer. Choosing between non-stick and cast iron plates depends on prioritizing ease of maintenance and scratch resistance versus long-lasting structural resilience.

Which Plate Material Is More Cost-Effective?

Non-stick plates offer a cost-effective solution for sandwich makers due to their lower upfront price and ease of cleaning, reducing maintenance expenses over time. Cast iron plates, while more durable and better for heat retention, require seasoning and careful upkeep, potentially increasing long-term costs despite their longevity. For budget-conscious users prioritizing convenience and consistent performance, non-stick plates generally provide greater overall value.

Final Verdict: Best Plate Choice for Longevity

Non-stick plates offer ease of cleaning and quick heat distribution but tend to wear down and lose effectiveness over time due to surface scratching and coating degradation. Cast iron plates boast unmatched durability and heat retention, resisting scratches and warping, making them ideal for long-term use despite requiring maintenance to prevent rust. For longevity, cast iron plates are the superior choice, ensuring consistent performance and extended lifespan in sandwich makers.

Non-stick plates vs Cast iron plates for sandwich maker durability Infographic

productvia.com

productvia.com