Direct drive motors in stand mixers offer superior power transmission by connecting the motor directly to the mixing mechanism, resulting in greater efficiency and reduced energy loss. Belt drive motors, while typically quieter and less expensive, can experience slippage and wear over time, reducing overall performance and requiring more maintenance. Choosing between the two depends on a balance of durability, power output, and long-term reliability for heavy-duty mixing tasks.

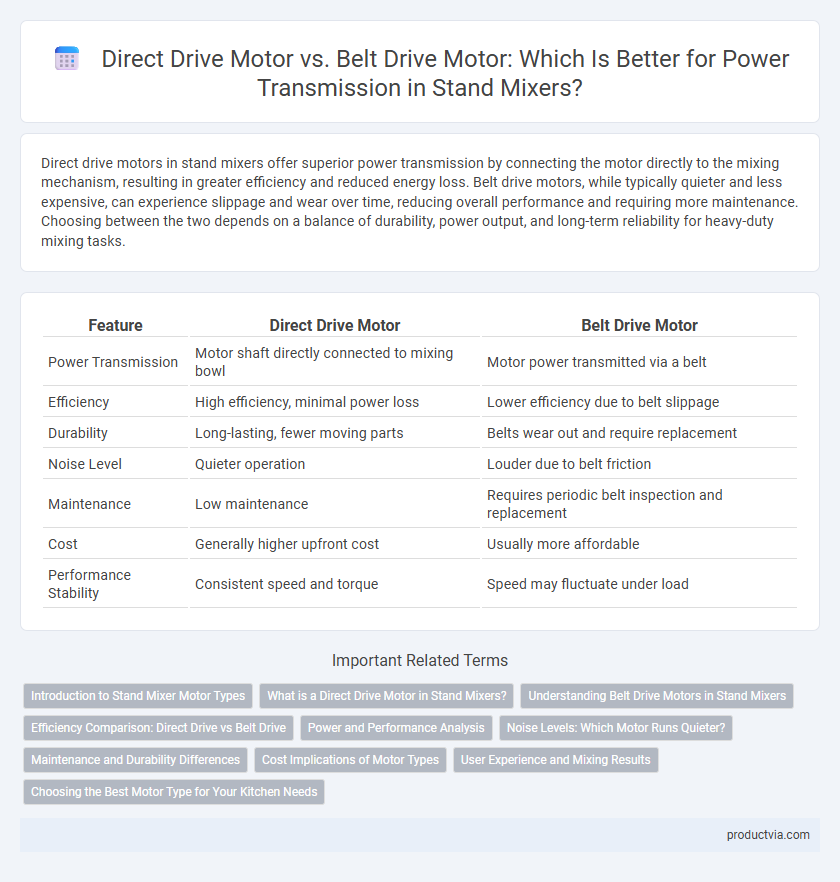

Table of Comparison

| Feature | Direct Drive Motor | Belt Drive Motor |

|---|---|---|

| Power Transmission | Motor shaft directly connected to mixing bowl | Motor power transmitted via a belt |

| Efficiency | High efficiency, minimal power loss | Lower efficiency due to belt slippage |

| Durability | Long-lasting, fewer moving parts | Belts wear out and require replacement |

| Noise Level | Quieter operation | Louder due to belt friction |

| Maintenance | Low maintenance | Requires periodic belt inspection and replacement |

| Cost | Generally higher upfront cost | Usually more affordable |

| Performance Stability | Consistent speed and torque | Speed may fluctuate under load |

Introduction to Stand Mixer Motor Types

Stand mixers utilize two primary motor types for power transmission: direct drive motors and belt drive motors. Direct drive motors connect the motor shaft directly to the mixing mechanism, offering higher efficiency, reduced noise, and increased durability. Belt drive motors, featuring a flexible belt between the motor and attachment hub, provide smoother operation and shock absorption but may require more maintenance and generate slightly more noise.

What is a Direct Drive Motor in Stand Mixers?

A direct drive motor in stand mixers connects the motor shaft directly to the mixing mechanism, eliminating the need for belts or pulleys, which results in more efficient power transmission and reduced energy loss. This design offers greater torque and durability, enhancing the mixer's ability to handle heavy dough and continuous mixing tasks. Direct drive motors also require less maintenance and produce less noise compared to belt drive systems.

Understanding Belt Drive Motors in Stand Mixers

Belt drive motors in stand mixers use a flexible belt to transfer power from the motor to the mixing head, offering smoother and quieter operation compared to direct drive systems. This setup allows for better vibration absorption, reducing wear on internal components and extending the mixer's lifespan. However, belt drive motors may require occasional belt replacement and skilled maintenance to ensure consistent performance.

Efficiency Comparison: Direct Drive vs Belt Drive

Direct drive motors in stand mixers offer higher efficiency by transferring power directly from the motor to the mixing mechanism, reducing energy loss and wear compared to belt drive systems. Belt drive motors experience power loss due to friction and slippage in the belt, resulting in lower overall efficiency and potential maintenance issues. This direct power transmission in direct drive mixers provides consistent torque and performance, making them more energy-efficient and durable for heavy-duty mixing tasks.

Power and Performance Analysis

Direct drive motors in stand mixers deliver superior power transmission by connecting the motor shaft directly to the mixing mechanism, resulting in higher torque and more efficient energy use. Belt drive motors exhibit slight power loss due to belt slippage and tension variability, which can reduce overall performance and consistency during heavy mixing tasks. For users prioritizing durable power and optimal performance, direct drive systems provide a more reliable and consistent mixing experience in demanding culinary applications.

Noise Levels: Which Motor Runs Quieter?

Direct drive motors in stand mixers produce less noise due to the direct connection between the motor and the mixing mechanism, eliminating vibrations caused by belts. Belt drive motors tend to generate higher noise levels because the belt can slip or stretch, causing additional sound and reduced efficiency. Overall, direct drive systems are preferred for quieter operation and consistent power transmission.

Maintenance and Durability Differences

Direct drive motors in stand mixers offer superior durability due to fewer moving parts and reduced mechanical wear, resulting in low maintenance needs. Belt drive motors require periodic belt replacement and tension adjustments, increasing maintenance frequency and potential downtime. The direct drive system ensures consistent power transmission with minimal service interruptions, making it ideal for heavy-duty or frequent use.

Cost Implications of Motor Types

Direct drive motors in stand mixers often result in lower maintenance costs and improved energy efficiency, leading to long-term savings despite potentially higher initial purchase prices. Belt drive motors typically have lower upfront costs but may require frequent belt replacements and adjustments, increasing ongoing maintenance expenses. Evaluating total cost of ownership reveals that direct drive mixers can offer better value over time due to reduced wear and fewer parts needing replacement.

User Experience and Mixing Results

Direct drive motors in stand mixers provide a more efficient power transmission, resulting in quieter operation and less maintenance compared to belt drive motors. Users experience consistent torque and smoother mixing performance, which enhances the quality of dough and batter texture. Belt drive motors may offer versatility but often produce more noise and slight power loss, impacting overall mixing results.

Choosing the Best Motor Type for Your Kitchen Needs

Direct drive motors in stand mixers offer superior power transmission efficiency and reduced maintenance due to fewer moving parts, making them ideal for heavy-duty mixing tasks. Belt drive motors provide smoother operation and quieter performance, which is beneficial for everyday kitchen use and lighter mixing requirements. Selecting the right motor depends on your frequency of use and mixing intensity, with direct drive favored for frequent, intensive baking and belt drive suited for occasional, quieter use.

Direct drive motor vs Belt drive motor for power transmission Infographic

productvia.com

productvia.com