Direct drive stand mixers offer a more efficient motor transmission by connecting the motor directly to the mixing mechanism, resulting in increased power and quieter operation. Belt drive mixers use a belt system to transfer motor energy, which can absorb shock and reduce motor strain but may lead to decreased power and increased maintenance. Choosing between direct drive and belt drive depends on the balance of performance preference and long-term durability needs.

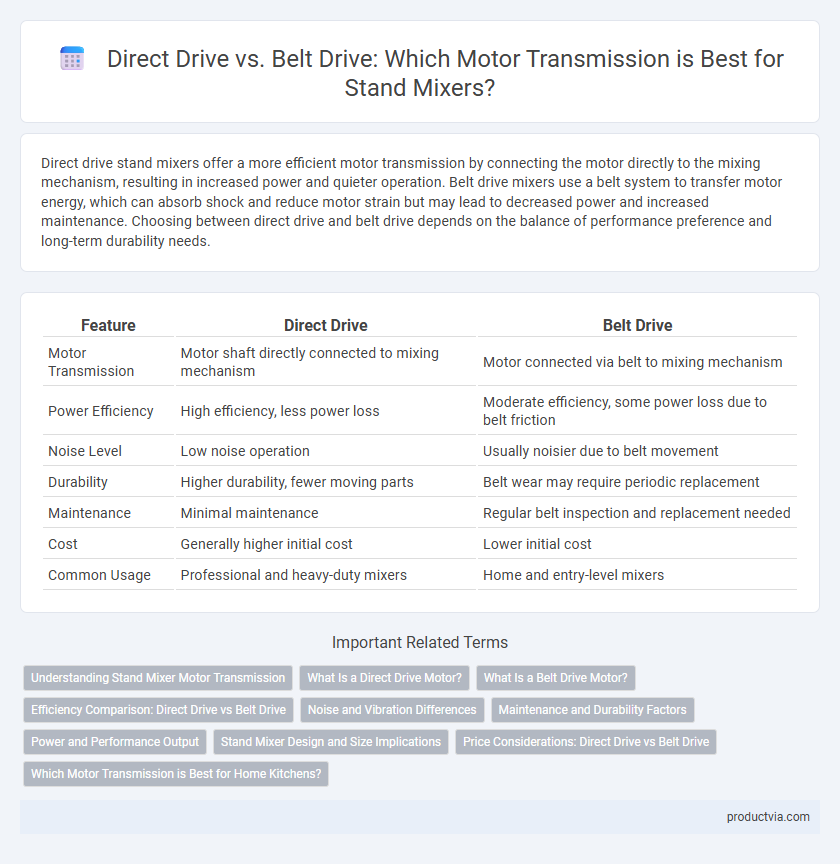

Table of Comparison

| Feature | Direct Drive | Belt Drive |

|---|---|---|

| Motor Transmission | Motor shaft directly connected to mixing mechanism | Motor connected via belt to mixing mechanism |

| Power Efficiency | High efficiency, less power loss | Moderate efficiency, some power loss due to belt friction |

| Noise Level | Low noise operation | Usually noisier due to belt movement |

| Durability | Higher durability, fewer moving parts | Belt wear may require periodic replacement |

| Maintenance | Minimal maintenance | Regular belt inspection and replacement needed |

| Cost | Generally higher initial cost | Lower initial cost |

| Common Usage | Professional and heavy-duty mixers | Home and entry-level mixers |

Understanding Stand Mixer Motor Transmission

Direct drive stand mixers offer increased power efficiency and durability by connecting the motor directly to the mixing bowl, reducing energy loss and maintenance compared to belt drive systems. Belt drive mixers use a rubber belt to transfer motor energy to the mixing mechanism, providing quieter operation and vibration reduction but at the expense of occasional belt replacements and slightly less torque. Choosing between direct drive and belt drive depends on the balance of power output, noise level, and long-term maintenance preferences for optimal stand mixer performance.

What Is a Direct Drive Motor?

A direct drive motor in a stand mixer connects the motor shaft directly to the mixing attachment, eliminating the need for intermediary components like belts or gears. This design offers increased efficiency, reduced noise, and enhanced durability by minimizing energy loss and mechanical wear. Direct drive systems provide consistent power delivery and precise control, making them ideal for heavy-duty mixing tasks.

What Is a Belt Drive Motor?

A belt drive motor in a stand mixer uses a flexible rubber or synthetic belt to transfer power from the motor to the mixing mechanism, allowing for smoother and quieter operation. This design reduces vibration and can extend the lifespan of the motor by absorbing shock and minimizing wear on direct connections. Belt drive systems typically offer easier maintenance and can handle varying speeds more efficiently compared to direct drive motors.

Efficiency Comparison: Direct Drive vs Belt Drive

Direct drive stand mixers deliver superior efficiency by connecting the motor directly to the agitator, reducing energy loss and maximizing power transfer. Belt drive models experience slight energy loss due to friction and slippage between the belt and pulleys, making them less efficient for heavy-duty mixing. Consequently, direct drive mixers often provide more consistent torque and improved performance in demanding baking tasks.

Noise and Vibration Differences

Direct drive stand mixers exhibit lower noise levels and reduced vibration due to the motor being directly connected to the mixing mechanism, minimizing energy loss and mechanical interference. Belt drive stand mixers tend to produce more noise and vibration because the belt's movement introduces additional friction and slack, which can lead to motor strain and uneven power transmission. Users seeking quieter operation and smoother performance often prefer direct drive models for their enhanced stability and reduced mechanical noise.

Maintenance and Durability Factors

Direct drive stand mixers feature a motor directly connected to the mixing head, resulting in fewer moving parts and reduced wear, which enhances overall durability and lowers maintenance needs. Belt drive models use a belt to transfer power, requiring periodic belt inspection and replacement due to potential stretching or snapping, impacting long-term reliability. Choosing direct drive mechanisms typically offers superior longevity and less frequent servicing compared to belt-driven designs in stand mixers.

Power and Performance Output

Direct drive stand mixers transmit motor power directly to the mixing mechanism, resulting in higher torque and more efficient performance ideal for heavy-duty mixing tasks. Belt drive systems provide smoother motor operation with reduced noise but may experience slight power loss due to belt slippage, making them better suited for lighter, less demanding mixing. Power output in direct drive mixers typically ranges from 250 to 1000 watts, delivering consistent speed and performance, while belt drive mixers often have lower wattage and variable speed control for flexibility.

Stand Mixer Design and Size Implications

Direct drive stand mixers feature motors connected directly to the mixing mechanism, resulting in a more compact and efficient design that reduces overall size and enhances torque delivery. Belt drive mixers incorporate a belt system to transfer motor power, allowing for quieter operation but typically increasing the appliance's footprint and complexity. The choice between direct and belt drive influences countertop space requirements, motor longevity, and the mixer's performance in handling heavy doughs or prolonged use.

Price Considerations: Direct Drive vs Belt Drive

Direct drive stand mixers typically have a higher upfront cost due to their efficient motor transmission design, which provides better power and durability. Belt drive mixers are generally more affordable, making them a popular choice for budget-conscious users, but they may require more maintenance over time due to belt wear. Price considerations should weigh the long-term reliability and motor efficiency of direct drive models against the lower initial investment of belt drive options.

Which Motor Transmission is Best for Home Kitchens?

Direct drive stand mixers offer superior motor efficiency and durability by connecting the motor directly to the mixing bowl, reducing power loss and mechanical wear. Belt drive mixers provide quieter operation and smoother motor performance but may require more maintenance due to belt wear and potential slippage. For home kitchens, direct drive is generally preferred for its robust power delivery and longevity, especially when mixing dense or heavy ingredients.

Direct drive vs Belt drive for motor transmission Infographic

productvia.com

productvia.com