Direct drive motors in stand mixers offer superior power efficiency and durability by connecting the motor directly to the mixing mechanism, reducing energy loss and wear. Belt-driven motors provide smoother operation and quieter performance, thanks to the flexible belt absorbing vibrations and motor jolts. Choosing between the two depends on preference for longevity and torque versus noise reduction and gentle mixing action.

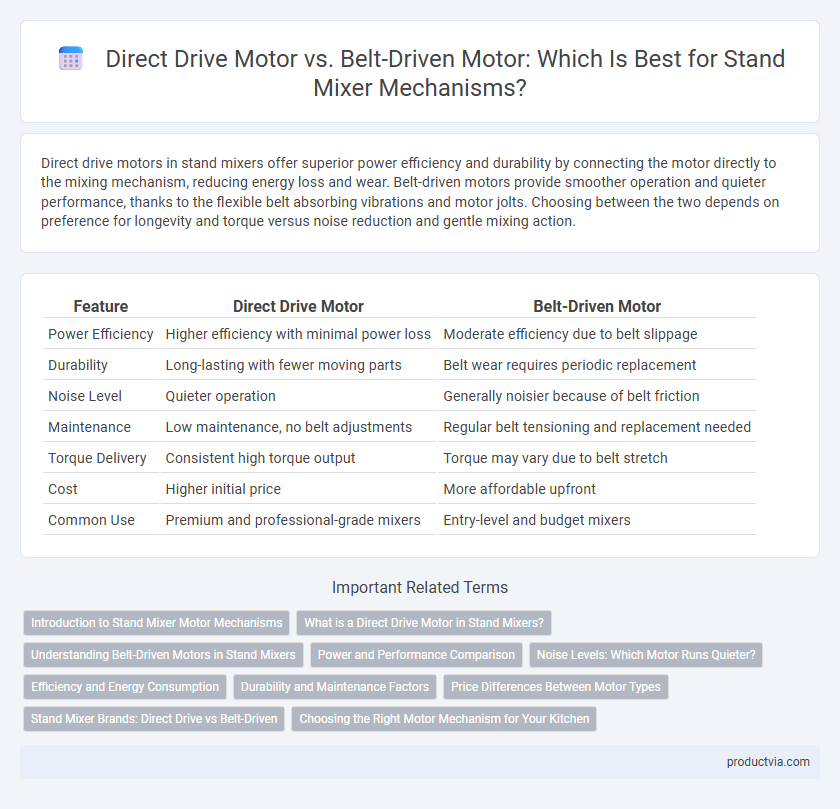

Table of Comparison

| Feature | Direct Drive Motor | Belt-Driven Motor |

|---|---|---|

| Power Efficiency | Higher efficiency with minimal power loss | Moderate efficiency due to belt slippage |

| Durability | Long-lasting with fewer moving parts | Belt wear requires periodic replacement |

| Noise Level | Quieter operation | Generally noisier because of belt friction |

| Maintenance | Low maintenance, no belt adjustments | Regular belt tensioning and replacement needed |

| Torque Delivery | Consistent high torque output | Torque may vary due to belt stretch |

| Cost | Higher initial price | More affordable upfront |

| Common Use | Premium and professional-grade mixers | Entry-level and budget mixers |

Introduction to Stand Mixer Motor Mechanisms

Stand mixers typically use two main types of motor mechanisms: direct drive and belt-driven systems. Direct drive motors connect the motor shaft directly to the mixing attachment, offering higher efficiency, reduced maintenance, and quieter operation. Belt-driven motors use a belt to transfer power from the motor to the attachment, providing smoother acceleration and improved torque control but potentially requiring more frequent maintenance due to belt wear.

What is a Direct Drive Motor in Stand Mixers?

A direct drive motor in stand mixers connects the motor directly to the mixing mechanism, eliminating the need for belts or gears. This design offers increased power efficiency, reduced noise, and less maintenance compared to belt-driven motors. High-end brands often use direct drive motors to provide consistent torque and durability during heavy mixing tasks.

Understanding Belt-Driven Motors in Stand Mixers

Belt-driven motors in stand mixers utilize a rubber belt to transfer power from the motor to the mixing attachment, offering smoother and quieter operation compared to direct drive systems. This mechanism reduces strain on the motor by absorbing shock and providing flexibility in RPM ranges, which is especially beneficial for heavy-duty mixing tasks. Belt-driven motors typically require more maintenance than direct drive motors but deliver reliable performance for home bakers seeking consistent results.

Power and Performance Comparison

Direct drive motors in stand mixers deliver superior power transfer and efficiency by connecting the motor directly to the mixing mechanism, resulting in consistent torque and enhanced performance for heavy-duty mixing tasks. Belt-driven motors generally produce more noise and experience power loss due to belt slippage, which can reduce mixing efficiency and durability over time. Stand mixers with direct drive systems outperform belt-driven counterparts in sustained power output, making them ideal for rigorous baking and cooking applications.

Noise Levels: Which Motor Runs Quieter?

Direct drive motors in stand mixers operate with less noise due to the motor being directly attached to the mixing mechanism, minimizing vibration and sound. Belt-driven motors generate more noise because the belts create friction and can slacken over time, causing rattling or squeaking sounds. For users prioritizing quieter kitchen appliances, stand mixers with direct drive motors are the superior choice.

Efficiency and Energy Consumption

Direct drive motors in stand mixers offer higher efficiency by transferring power directly from the motor to the mixing mechanism, reducing energy loss and improving speed control. Belt-driven motors experience greater energy consumption due to friction and slippage within the belt system, which can lead to decreased mechanical efficiency and increased wear over time. Choosing a direct drive motor maximizes energy efficiency and prolongs the machine's operational lifespan.

Durability and Maintenance Factors

Direct drive motors in stand mixers offer enhanced durability by minimizing mechanical parts prone to wear, resulting in fewer maintenance requirements and longer operational life. Belt-driven motors, while often quieter and easier to repair due to replaceable belts, tend to experience faster wear and require more frequent maintenance. Choosing a direct drive motor improves reliability and reduces downtime, making it ideal for heavy-duty or frequent mixing tasks.

Price Differences Between Motor Types

Direct drive motors in stand mixers typically come at a higher price point due to their efficiency, durability, and quieter operation, often found in premium models from brands like KitchenAid and Bosch. Belt-driven motors are more cost-effective, making them common in budget-friendly mixers, but they may require more maintenance due to wear on belts and reduced energy transfer. Consumers seeking long-term investment benefits often prefer direct drive motors despite the initial higher cost, while casual users might opt for belt-driven mixers to save upfront.

Stand Mixer Brands: Direct Drive vs Belt-Driven

Stand mixers with direct drive motors, such as KitchenAid, offer superior torque and durability by connecting the motor directly to the mixing mechanism, resulting in efficient power transfer and quieter operation. Belt-driven models, often found in brands like Cuisinart and Hamilton Beach, use a flexible belt to transfer motor power, generally producing less torque but often providing smoother starts and quieter performance under light mixing tasks. Choosing between direct drive and belt-driven motor stand mixers depends on the user's need for heavy-duty mixing power or versatile, quieter operation in everyday food preparation.

Choosing the Right Motor Mechanism for Your Kitchen

Direct drive motors in stand mixers offer enhanced durability and quieter operation by connecting the motor directly to the mixing mechanism, reducing energy loss and maintenance needs. Belt-driven motors provide smoother torque control and are often more affordable but may require more frequent belt replacements due to wear. Selecting the right motor mechanism depends on your cooking frequency, desired noise levels, and budget, with direct drive motors preferred for heavy-duty, long-term use.

Direct drive motor vs Belt-driven motor for stand mixer mechanism Infographic

productvia.com

productvia.com