Metal gears in stand mixers offer superior durability and strength, ensuring long-lasting performance under heavy loads and frequent use. Nylon gears provide quieter operation and reduced weight, enhancing overall machine efficiency but may wear out faster under intense mixing tasks. Choosing metal gears is ideal for heavy-duty mixing needs, while nylon gears suit lighter, everyday baking activities.

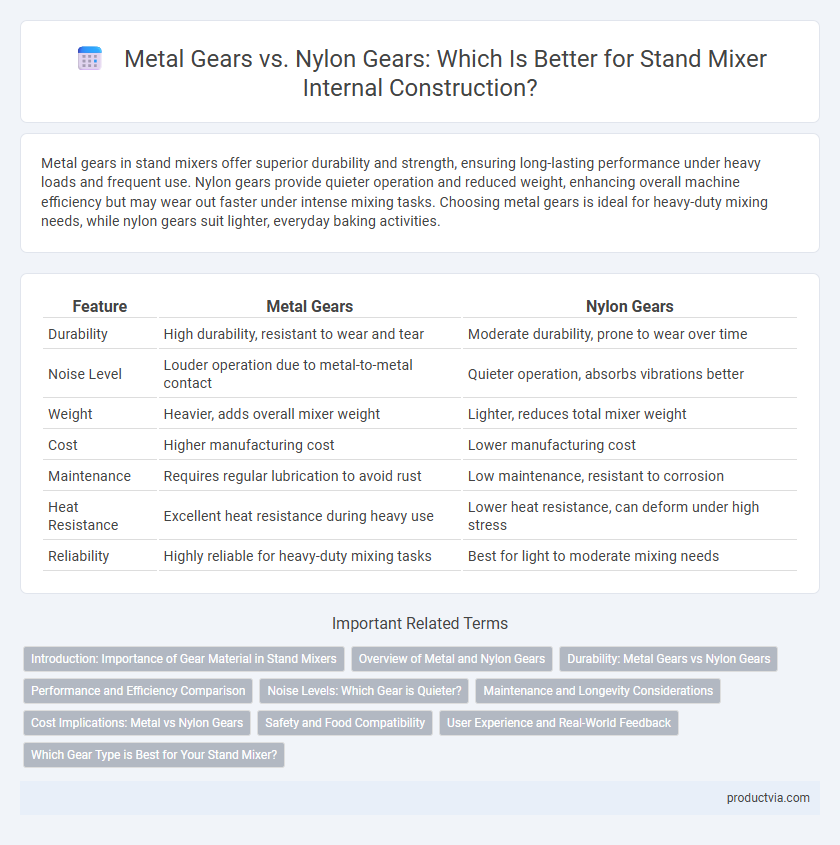

Table of Comparison

| Feature | Metal Gears | Nylon Gears |

|---|---|---|

| Durability | High durability, resistant to wear and tear | Moderate durability, prone to wear over time |

| Noise Level | Louder operation due to metal-to-metal contact | Quieter operation, absorbs vibrations better |

| Weight | Heavier, adds overall mixer weight | Lighter, reduces total mixer weight |

| Cost | Higher manufacturing cost | Lower manufacturing cost |

| Maintenance | Requires regular lubrication to avoid rust | Low maintenance, resistant to corrosion |

| Heat Resistance | Excellent heat resistance during heavy use | Lower heat resistance, can deform under high stress |

| Reliability | Highly reliable for heavy-duty mixing tasks | Best for light to moderate mixing needs |

Introduction: Importance of Gear Material in Stand Mixers

Gear material in stand mixers directly affects durability, performance efficiency, and noise levels during operation. Metal gears offer superior strength and longevity, making them ideal for heavy-duty mixing tasks, while nylon gears provide quieter operation and flexibility but may wear faster under high stress. Selecting the appropriate gear material ensures optimal mixer functionality and lifespan tailored to user needs.

Overview of Metal and Nylon Gears

Metal gears in stand mixers provide superior durability and strength, ensuring long-lasting performance under heavy use. Nylon gears offer quieter operation and reduced friction, contributing to smoother mixing but may wear out faster over time. Choosing between metal and nylon gears depends on the balance between durability and noise level preferred by the user.

Durability: Metal Gears vs Nylon Gears

Metal gears in stand mixers offer superior durability due to their resistance to wear and ability to withstand high torque during heavy-duty mixing tasks. Nylon gears, while quieter and lighter, tend to wear out faster and may degrade under prolonged stress, making them less ideal for frequent or intense use. Choosing metal gears enhances the longevity and reliability of the stand mixer's internal mechanism, especially for professional or high-volume baking.

Performance and Efficiency Comparison

Metal gears in stand mixers deliver superior durability and handle higher torque loads, ensuring consistent performance during heavy-duty mixing tasks. Nylon gears offer quieter operation and better resistance to wear from friction but may wear faster under continuous heavy use. Overall, metal gears maximize efficiency and longevity in professional or frequent use, while nylon gears suit lighter, less demanding applications.

Noise Levels: Which Gear is Quieter?

Metal gears in stand mixers are generally noisier due to their rigid structure causing louder operational sounds during mixing tasks. Nylon gears offer quieter performance as their flexible material absorbs vibration and reduces noise output significantly. Choosing nylon gears enhances user comfort by minimizing distracting mechanical sounds in kitchen environments.

Maintenance and Longevity Considerations

Metal gears in stand mixers offer superior durability and require less frequent maintenance compared to nylon gears, which can wear down faster under heavy use. Nylon gears tend to be quieter but may need regular inspection and replacement to prevent malfunction. Proper lubrication and occasional gear checks extend the longevity of both materials, but metal gears generally ensure a longer-lasting, reliable performance in high-torque applications.

Cost Implications: Metal vs Nylon Gears

Metal gears in stand mixers offer superior durability and resistance to wear, leading to longer product lifespan but come with higher manufacturing costs affecting retail prices. Nylon gears reduce production expenses due to lower material and fabrication costs, making mixers more affordable but potentially compromising long-term reliability under heavy use. Choosing metal gears typically results in higher upfront investment while nylon gears provide cost-effective solutions suitable for light to moderate mixing tasks.

Safety and Food Compatibility

Metal gears in stand mixers offer superior durability and enhanced safety due to their resistance to wear and reduced risk of contamination from gear degradation. Nylon gears, while quieter and lighter, may pose food safety concerns over time as they are prone to wear and potential microplastic release in the mixing bowl. Choosing metal gears ensures higher food compatibility and longevity in food preparation environments.

User Experience and Real-World Feedback

Metal gears in stand mixers deliver superior durability and consistent performance, reducing the risk of gear stripping during heavy-duty mixing tasks. Nylon gears offer quieter operation and smoother engagement but may wear out faster under frequent or intense use. Real-world feedback highlights that users prioritizing longevity and strength tend to prefer metal gears, while those valuing noise reduction often favor nylon gear models.

Which Gear Type is Best for Your Stand Mixer?

Metal gears in stand mixers offer superior durability and strength, ideal for heavy-duty mixing tasks or frequent use in baking. Nylon gears provide quieter operation and are often lighter, making them suitable for occasional or light household mixing without the noise. Choosing between metal and nylon gears depends on your mixing frequency and task intensity, with metal gears best for intensive use and nylon gears for quieter, less demanding applications.

Metal gears vs Nylon gears for internal construction Infographic

productvia.com

productvia.com