Automatic oil filtration systems in deep fryer pets ensure continuous cleaning by removing food particles and debris during cooking, prolonging oil life and maintaining consistent frying quality. Manual oil draining requires stopping the fryer to pour out used oil, which can be time-consuming and increase the risk of spills or burns. Regular use of automatic filtration enhances maintenance efficiency and promotes safer handling compared to manual draining methods.

Table of Comparison

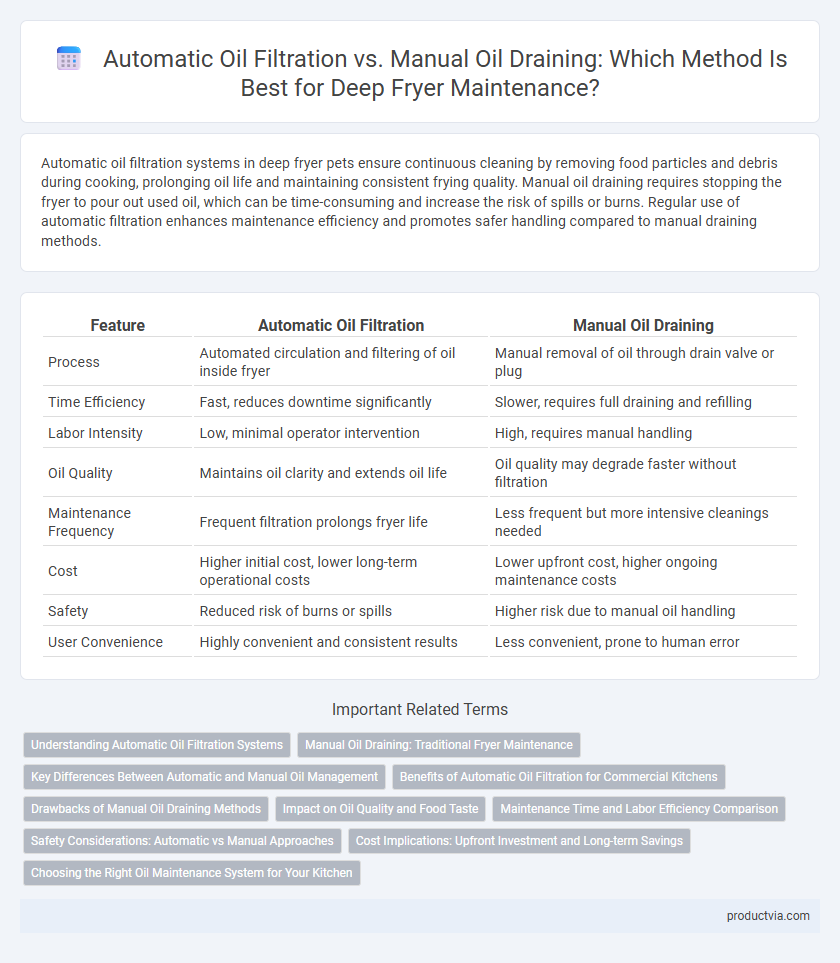

| Feature | Automatic Oil Filtration | Manual Oil Draining |

|---|---|---|

| Process | Automated circulation and filtering of oil inside fryer | Manual removal of oil through drain valve or plug |

| Time Efficiency | Fast, reduces downtime significantly | Slower, requires full draining and refilling |

| Labor Intensity | Low, minimal operator intervention | High, requires manual handling |

| Oil Quality | Maintains oil clarity and extends oil life | Oil quality may degrade faster without filtration |

| Maintenance Frequency | Frequent filtration prolongs fryer life | Less frequent but more intensive cleanings needed |

| Cost | Higher initial cost, lower long-term operational costs | Lower upfront cost, higher ongoing maintenance costs |

| Safety | Reduced risk of burns or spills | Higher risk due to manual oil handling |

| User Convenience | Highly convenient and consistent results | Less convenient, prone to human error |

Understanding Automatic Oil Filtration Systems

Automatic oil filtration systems in deep fryers extend oil life by continuously removing food particles and impurities during operation, reducing oil degradation and improving fry quality. These systems feature built-in pumps and filters that circulate oil through filtration media, minimizing labor and ensuring consistent oil cleanliness without downtime. Compared to manual oil draining, automatic filtration enhances efficiency, reduces maintenance frequency, and lowers operational costs in commercial frying environments.

Manual Oil Draining: Traditional Fryer Maintenance

Manual oil draining in traditional fryer maintenance requires physically removing used oil from the fryer tank, often involving draining it into containers for disposal or filtering. This method demands regular monitoring to prevent oil degradation that affects food quality and fryer longevity. Although time-consuming, manual draining allows for thorough inspection and cleaning of fryer components, extending equipment lifespan when performed diligently.

Key Differences Between Automatic and Manual Oil Management

Automatic oil filtration systems in deep fryers continuously remove food particles and extend oil life through built-in filtration cycles, reducing labor and improving oil quality. Manual oil draining requires operators to periodically drain and replace oil, increasing downtime and the risk of inconsistent filtration. Automatic systems ensure consistent oil cleanliness and temperature control, while manual methods depend heavily on operator diligence and timing.

Benefits of Automatic Oil Filtration for Commercial Kitchens

Automatic oil filtration systems in commercial deep fryers significantly extend oil life by continuously removing food particles and impurities, reducing the frequency of oil changes and lowering overall operating costs. These systems enhance food quality by maintaining consistent oil clarity and temperature, which leads to better frying results and improved customer satisfaction. Automated filtration also minimizes labor requirements and safety hazards associated with manual oil draining, promoting a more efficient and safer kitchen environment.

Drawbacks of Manual Oil Draining Methods

Manual oil draining for deep fryer maintenance often leads to inconsistent filtration, resulting in shorter oil lifespan and degraded food quality. This method poses safety risks due to hot oil spills and requires significant labor, increasing downtime and operational costs. Without proper filtering, manual draining can cause rapid accumulation of food particles, accelerating oil deterioration and fryer damage.

Impact on Oil Quality and Food Taste

Automatic oil filtration systems significantly prolong oil life by continuously removing food particles and contaminants, which helps maintain consistent oil quality and preserves the authentic taste of fried foods. Manual oil draining requires complete oil replacement more frequently, leading to flavor degradation and potential food quality inconsistencies due to oil breakdown. Consistently filtered oil reduces harmful compounds, ensuring better food flavor and healthier frying conditions over time.

Maintenance Time and Labor Efficiency Comparison

Automatic oil filtration systems significantly reduce maintenance time by continuously removing food particles and contaminants without requiring fryer shutdowns, enhancing overall labor efficiency. Manual oil draining demands complete fryer cool-down and oil removal, resulting in longer downtime and increased labor input. Using automatic filtration not only streamlines fryer upkeep but also extends oil life, minimizing the frequency of full oil changes.

Safety Considerations: Automatic vs Manual Approaches

Automatic oil filtration systems enhance safety in deep fryer maintenance by minimizing direct contact with hot oil, reducing burn risks and exposure to hazardous fumes. Manual oil draining requires careful handling to avoid spills and burns, often increasing the likelihood of accidents due to hot oil splashes. Integrating automatic filtration improves operational safety by automating oil circulation and filtration, mitigating human error during maintenance procedures.

Cost Implications: Upfront Investment and Long-term Savings

Automatic oil filtration systems for deep fryers require a higher upfront investment but significantly reduce long-term costs by extending oil life and minimizing labor expenses. Manual oil draining involves lower initial costs but increases ongoing expenses due to frequent oil replacement and labor-intensive cleaning processes. Businesses aiming for cost efficiency typically benefit from the balance of automation's higher initial price against sustained savings in oil and labor over time.

Choosing the Right Oil Maintenance System for Your Kitchen

Automatic oil filtration systems enhance fryer performance by continuously removing food particles, extending oil life by up to 50%, and reducing labor costs in busy kitchens. Manual oil draining requires more frequent oil changes and increases the risk of operator error, impacting food quality and safety. Selecting an oil maintenance system depends on kitchen volume, with automatic filtration ideal for high-traffic environments seeking consistent oil quality and manual draining suited for smaller operations with lower fry demand.

Automatic oil filtration vs Manual oil draining for fryer maintenance Infographic

productvia.com

productvia.com