Immersion heaters provide efficient and rapid heating by directly contacting the oil, ensuring consistent temperature control in deep fryers. Radiant heat systems, while less direct, offer even heat distribution and reduced risk of overheating localized areas. Choosing between immersion and radiant heat depends on the need for precise temperature management and energy efficiency in deep frying applications.

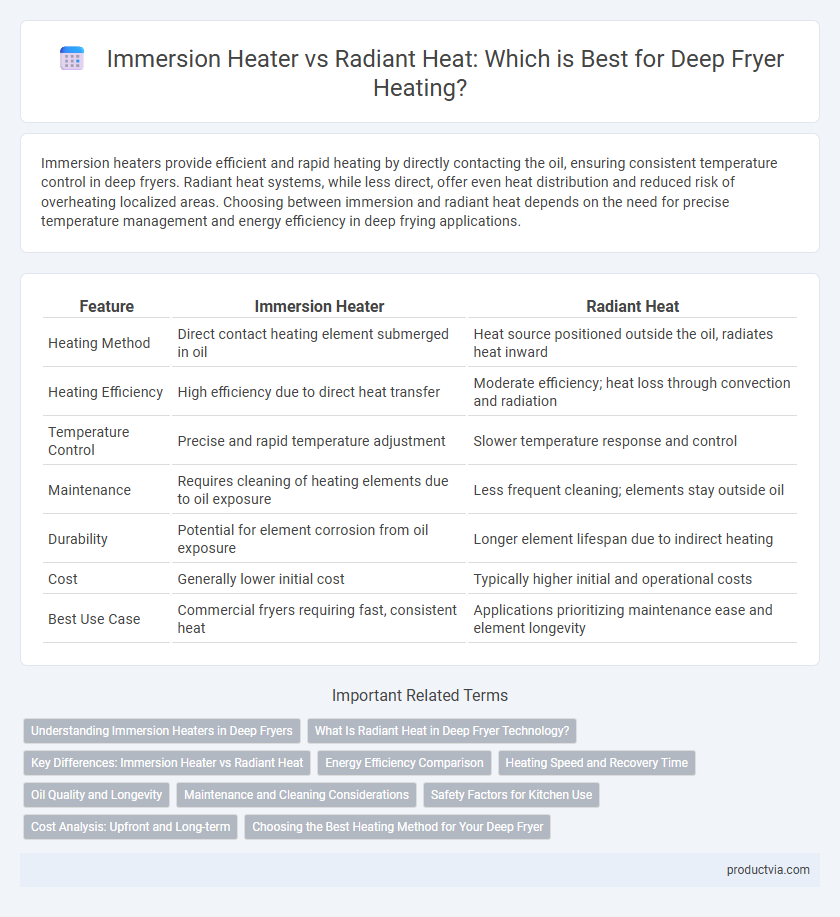

Table of Comparison

| Feature | Immersion Heater | Radiant Heat |

|---|---|---|

| Heating Method | Direct contact heating element submerged in oil | Heat source positioned outside the oil, radiates heat inward |

| Heating Efficiency | High efficiency due to direct heat transfer | Moderate efficiency; heat loss through convection and radiation |

| Temperature Control | Precise and rapid temperature adjustment | Slower temperature response and control |

| Maintenance | Requires cleaning of heating elements due to oil exposure | Less frequent cleaning; elements stay outside oil |

| Durability | Potential for element corrosion from oil exposure | Longer element lifespan due to indirect heating |

| Cost | Generally lower initial cost | Typically higher initial and operational costs |

| Best Use Case | Commercial fryers requiring fast, consistent heat | Applications prioritizing maintenance ease and element longevity |

Understanding Immersion Heaters in Deep Fryers

Immersion heaters in deep fryers directly heat the oil by submerging heating elements into the fryer oil, ensuring rapid and uniform temperature rise. These heaters provide efficient energy transfer, minimizing heat loss compared to external radiant heat sources that rely on indirect heating of the oil container. The design of immersion heaters promotes consistent frying temperatures, which is crucial for maintaining food quality and reducing cooking time.

What Is Radiant Heat in Deep Fryer Technology?

Radiant heat in deep fryer technology involves heating elements that emit infrared energy to directly heat the cooking oil without physical contact, providing rapid and even temperature distribution. Unlike immersion heaters submerged in oil, radiant heaters reduce oil contamination and enable precise temperature control for consistent frying results. This method enhances energy efficiency and minimizes maintenance by preventing oil degradation associated with direct heating elements.

Key Differences: Immersion Heater vs Radiant Heat

Immersion heaters transfer heat directly to the oil by electric elements submerged within the fryer, ensuring rapid and even heating, which improves energy efficiency and temperature control. Radiant heat relies on external heat sources like gas burners or electric coils positioned beneath the fryer, causing slower, less uniform warming of the oil. Key differences include immersion heaters' faster heat response, increased energy efficiency, and more precise temperature regulation compared to the indirect, slower, and sometimes uneven heat distribution of radiant systems.

Energy Efficiency Comparison

Immersion heaters in deep fryers provide direct contact with the oil, resulting in faster heat transfer and reduced energy loss, making them more energy-efficient compared to radiant heat systems. Radiant heat elements, positioned outside the oil bath, typically experience higher heat dissipation and take longer to reach desired temperatures, leading to increased energy consumption. Studies show immersion heating can reduce energy usage by up to 15% in commercial deep fryers versus traditional radiant heating methods.

Heating Speed and Recovery Time

Immersion heaters in deep fryers provide faster heating speeds by directly transferring heat to the oil, reducing preheat times significantly. Radiant heat elements rely on indirect heat transfer, resulting in slower heat-up and longer recovery times after introducing cold food. Faster recovery times with immersion heaters ensure consistent frying temperatures, improving cooking efficiency and food quality.

Oil Quality and Longevity

Immersion heaters provide direct heat transfer to the oil, maintaining consistent temperatures that preserve oil quality by minimizing oxidation and thermal degradation. Radiant heat elements, positioned outside the oil, often cause temperature fluctuations that accelerate oil breakdown and reduce frying life. Choosing immersion heating extends oil longevity, improving food taste while lowering oil replacement frequency.

Maintenance and Cleaning Considerations

Immersion heaters in deep fryers offer straightforward maintenance due to their direct contact with oil, enabling quicker heat transfer but requiring regular cleaning to prevent carbon build-up and ensure efficient operation. Radiant heat elements, positioned outside the oil container, reduce oil contamination and simplify cleaning as they avoid direct exposure to grease, yet they may need periodic inspection for heat uniformity and element wear. Choosing between these heating methods hinges on balancing ease of cleaning immersion heaters demand against the lower maintenance burden and longer lifespan often associated with radiant heat systems.

Safety Factors for Kitchen Use

Immersion heaters in deep fryers provide direct heating through submerged heating elements, reducing the risk of hotspots and promoting even oil temperature, which enhances safety by preventing oil overheating and potential fire hazards. Radiant heat systems rely on external heating sources, which may cause uneven oil temperatures and increase the risk of oil degradation or combustion, posing greater safety concerns in busy kitchen environments. Choosing immersion heaters ensures a controlled, stable heating process that minimizes accident risks and supports safer kitchen operations.

Cost Analysis: Upfront and Long-term

Immersion heaters typically have a higher upfront cost due to their more complex design and materials but offer superior energy efficiency, leading to lower long-term operational expenses. Radiant heat elements are generally less expensive at purchase but may consume more electricity over time, increasing total operating costs. Evaluating the total cost of ownership requires balancing the initial investment against energy savings and maintenance frequency.

Choosing the Best Heating Method for Your Deep Fryer

Immersion heaters provide direct contact heating by submerging the heating element into the cooking oil, resulting in faster temperature responsiveness and energy efficiency for deep fryers. Radiant heat elements transfer heat from a surface or coil outside the oil, offering more even heat distribution but slower temperature adjustment. Selecting the ideal heating method depends on factors like desired cooking speed, energy consumption, and fryer design, with immersion heaters often preferred for commercial kitchens needing rapid heat-up times.

Immersion Heater vs Radiant Heat for deep fryer heating Infographic

productvia.com

productvia.com