The oil filtration system in a deep fryer pet enhances the frying process by continuously filtering out food particles and impurities, ensuring cleaner oil and better-tasting food. Traditional oil drain methods require manual draining and replacement of oil, which can be time-consuming and less effective at maintaining oil quality. Utilizing oil filtration extends the oil's lifespan, reduces waste, and improves overall frying efficiency.

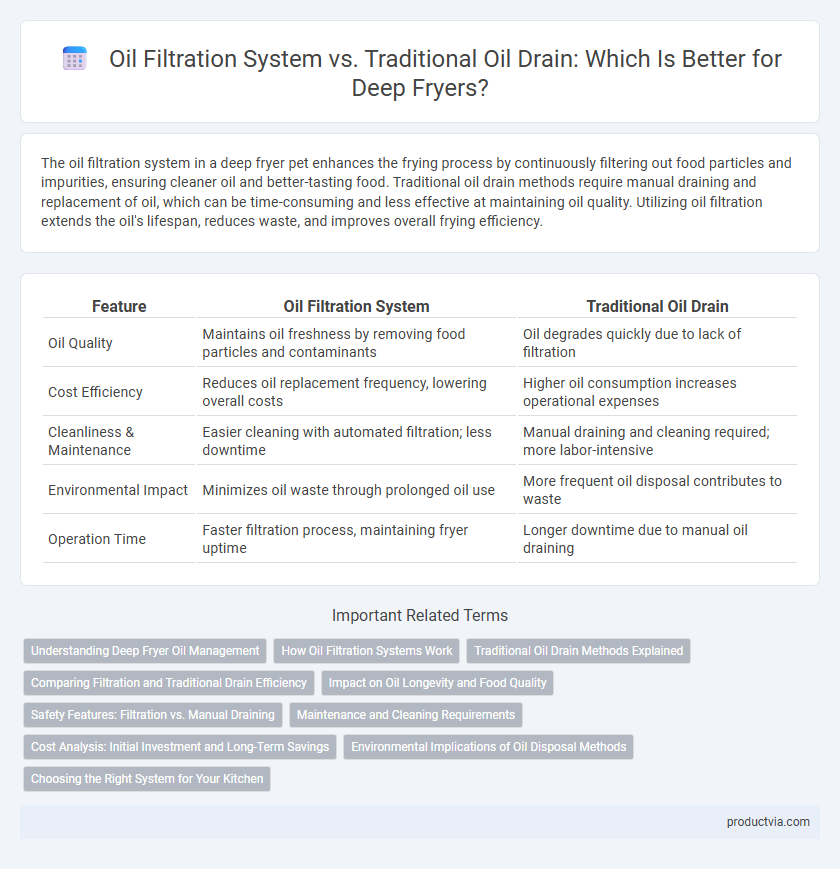

Table of Comparison

| Feature | Oil Filtration System | Traditional Oil Drain |

|---|---|---|

| Oil Quality | Maintains oil freshness by removing food particles and contaminants | Oil degrades quickly due to lack of filtration |

| Cost Efficiency | Reduces oil replacement frequency, lowering overall costs | Higher oil consumption increases operational expenses |

| Cleanliness & Maintenance | Easier cleaning with automated filtration; less downtime | Manual draining and cleaning required; more labor-intensive |

| Environmental Impact | Minimizes oil waste through prolonged oil use | More frequent oil disposal contributes to waste |

| Operation Time | Faster filtration process, maintaining fryer uptime | Longer downtime due to manual oil draining |

Understanding Deep Fryer Oil Management

The oil filtration system in deep fryers significantly enhances oil management by removing food particles and impurities, extending oil life and maintaining frying quality. Traditional oil drains require manual draining and oil replacement, leading to more frequent oil changes and higher operational costs. Effective oil filtration reduces downtime, ensures consistent food taste, and promotes environmentally friendly practices by minimizing oil waste.

How Oil Filtration Systems Work

Oil filtration systems in deep fryers continuously remove food particles and impurities from the cooking oil through fine mesh filters or centrifugal separation, maintaining oil clarity and extending its usable life. This process reduces the frequency of oil changes compared to traditional oil drains, which require manual drainage and replacement after every use. By preserving oil quality, filtration systems enhance food flavor, reduce operating costs, and promote a more efficient frying process.

Traditional Oil Drain Methods Explained

Traditional oil drain methods for deep fryers typically involve manually removing used oil through a valve or spigot, which can be time-consuming and prone to spillage. This process often requires draining the fryer into large containers, increasing the risk of burns and contamination. Compared to oil filtration systems, traditional draining lacks efficiency in removing food particles and extending oil life, leading to higher oil replacement costs.

Comparing Filtration and Traditional Drain Efficiency

Oil filtration systems in deep fryers enhance efficiency by continuously removing food particles and contaminants, resulting in prolonged oil life and consistent cooking quality. Traditional oil drains require complete oil replacement, leading to higher oil consumption and increased downtime for cleaning. Filtration systems reduce operational costs and improve frying performance compared to traditional oil drain methods.

Impact on Oil Longevity and Food Quality

Oil filtration systems in deep fryers significantly extend oil longevity by continuously removing food particles and contaminants, reducing oil degradation compared to traditional oil drains that only allow periodic oil replacement. This continual filtration preserves oil quality, resulting in more consistent cooking temperatures and improved food taste and texture. Traditional oil drain methods promote faster oil breakdown, leading to more frequent oil changes and potential negative impacts on food quality such as off-flavors and uneven frying.

Safety Features: Filtration vs. Manual Draining

Oil filtration systems in deep fryers significantly enhance safety by reducing hot oil exposure and minimizing the risk of spills during the filtration process. Traditional oil drains require manual handling, increasing the likelihood of burns and accidents due to hot oil splashes. Filtration mechanisms also help maintain oil quality by removing food particles, which prevents oil degradation and reduces fire hazards associated with overheated or contaminated oil.

Maintenance and Cleaning Requirements

The oil filtration system in a deep fryer significantly reduces maintenance and cleaning frequency by continuously filtering out food particles and extending oil life, leading to less frequent oil changes. Traditional oil drain systems require complete oil replacement more often, necessitating labor-intensive cleaning to remove leftover residues and prevent contamination. Utilizing an oil filtration system enhances operational efficiency and lowers long-term maintenance costs by maintaining cleaner oil and fryer components.

Cost Analysis: Initial Investment and Long-Term Savings

The oil filtration system in deep fryers requires a higher initial investment compared to traditional oil drain methods but offers significant long-term savings by extending oil life and reducing replacement frequency. Traditional oil drains have lower upfront costs but lead to increased expenses over time due to more frequent oil changes and higher waste disposal fees. Investing in an oil filtration system optimizes operational costs, enhances fryer efficiency, and improves overall profitability in commercial kitchen settings.

Environmental Implications of Oil Disposal Methods

Oil filtration systems for deep fryers significantly reduce the frequency of oil replacement, minimizing waste generation and lowering environmental impact compared to traditional oil drain methods that require frequent disposal of used oil. Traditional oil drain practices often lead to improper oil disposal, increasing the risk of soil and water contamination due to toxic compounds found in spent cooking oil. By enabling extended oil use and safer recycling options, filtration systems contribute to sustainable kitchen operations and reduce ecological hazards associated with cooking oil waste.

Choosing the Right System for Your Kitchen

An oil filtration system preserves cooking oil quality by removing food particles and extending oil life, reducing waste and costs in busy kitchens. Traditional oil drain methods require complete oil replacement, increasing expenses and downtime for cleaning. Selecting a filtration system enhances kitchen efficiency, maintaining consistent food flavor and safety while minimizing environmental impact.

Oil filtration system vs traditional oil drain for deep fryer Infographic

productvia.com

productvia.com