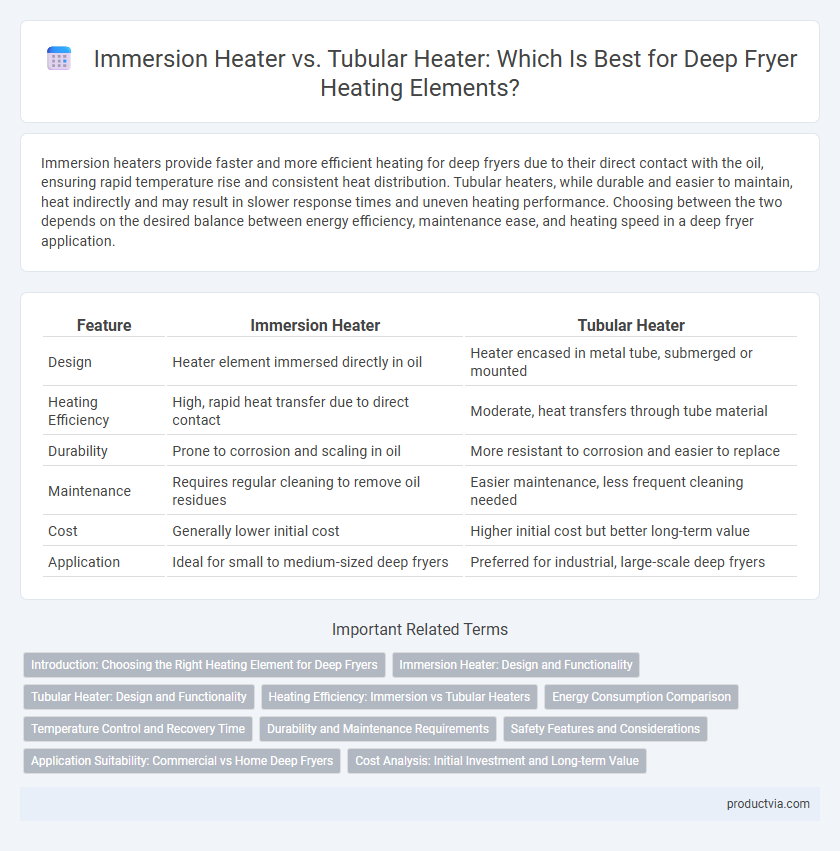

Immersion heaters provide faster and more efficient heating for deep fryers due to their direct contact with the oil, ensuring rapid temperature rise and consistent heat distribution. Tubular heaters, while durable and easier to maintain, heat indirectly and may result in slower response times and uneven heating performance. Choosing between the two depends on the desired balance between energy efficiency, maintenance ease, and heating speed in a deep fryer application.

Table of Comparison

| Feature | Immersion Heater | Tubular Heater |

|---|---|---|

| Design | Heater element immersed directly in oil | Heater encased in metal tube, submerged or mounted |

| Heating Efficiency | High, rapid heat transfer due to direct contact | Moderate, heat transfers through tube material |

| Durability | Prone to corrosion and scaling in oil | More resistant to corrosion and easier to replace |

| Maintenance | Requires regular cleaning to remove oil residues | Easier maintenance, less frequent cleaning needed |

| Cost | Generally lower initial cost | Higher initial cost but better long-term value |

| Application | Ideal for small to medium-sized deep fryers | Preferred for industrial, large-scale deep fryers |

Introduction: Choosing the Right Heating Element for Deep Fryers

Immersion heaters provide direct contact between the heating element and the oil, allowing for faster heat transfer and more efficient frying performance in deep fryers. Tubular heaters, enclosed within a metal sheath, offer durability and ease of maintenance but may result in slower heat response times. Selecting the appropriate heating element depends on balancing rapid heating needs with long-term durability requirements for optimal deep fryer operation.

Immersion Heater: Design and Functionality

The immersion heater in deep fryers consists of a heating element directly submerged in the oil, providing rapid and even heat transfer for consistent frying temperatures. Its design typically includes a corrosion-resistant sheath and compact coil configuration, ensuring durability and efficient energy use. The direct contact heating mechanism minimizes heat loss and accelerates cooking time compared to tubular heaters.

Tubular Heater: Design and Functionality

Tubular heaters for deep fryer heating elements feature a durable metal sheath that encases the heating coil, providing efficient heat transfer and resistance to corrosion from hot oil. Their customizable design allows for various shapes and sizes, enabling precise temperature control and uniform heating essential for consistent frying results. This functionality ensures energy efficiency and longevity, making tubular heaters a preferred choice in commercial deep fryer applications.

Heating Efficiency: Immersion vs Tubular Heaters

Immersion heaters offer superior heating efficiency for deep fryers by transferring heat directly to the oil, minimizing thermal loss and ensuring rapid temperature rise. Tubular heaters, while durable and versatile, require a heat transfer medium like a metal sheath, which can slow heating speed and reduce overall energy efficiency. Choosing immersion heaters results in faster oil heating, improved temperature control, and lower energy consumption compared to tubular options.

Energy Consumption Comparison

Immersion heaters typically offer faster heat transfer and higher thermal efficiency, resulting in lower energy consumption for deep fryer heating elements compared to tubular heaters. Tubular heaters, while more durable and easier to maintain, often exhibit slower heat transfer rates, leading to increased energy use during extended frying cycles. Selecting an immersion heater can significantly reduce electricity costs by optimizing energy usage in commercial and industrial deep fryer operations.

Temperature Control and Recovery Time

Immersion heaters provide faster temperature recovery times in deep fryers due to their direct contact with the cooking oil, enabling precise temperature control essential for consistent frying results. Tubular heaters, though durable and versatile, typically exhibit slower heat transfer, leading to less responsive temperature adjustments and longer recovery periods. Choosing an immersion heater enhances energy efficiency and maintains optimal frying temperatures, reducing oil degradation and improving food quality.

Durability and Maintenance Requirements

Immersion heaters offer superior durability in deep fryers due to their corrosion-resistant design and robust construction, minimizing the risk of failure in high-temperature oil environments. Tubular heaters require more frequent maintenance because their exposed elements are prone to scaling and oil buildup, which can reduce heat efficiency and lifespan. Choosing immersion heaters reduces downtime and maintenance costs, making them ideal for continuous, heavy-duty frying operations.

Safety Features and Considerations

Immersion heaters for deep fryer heating elements offer direct contact with cooking oil, ensuring rapid heat transfer and minimizing overheating risks through built-in thermal cutoffs and high-temperature insulation. Tubular heaters, while effective, are encased in metal tubes that prevent exposure to oil but may require additional safety sensors to avoid dry firing and metal fatigue. Selecting between immersion and tubular heaters involves evaluating oil compatibility, protective casings, and integrated safety mechanisms to prevent electrical hazards and maintain consistent cooking temperatures.

Application Suitability: Commercial vs Home Deep Fryers

Immersion heaters offer rapid heating and are ideal for commercial deep fryers due to their durability and efficient heat transfer in large oil volumes. Tubular heaters suit home deep fryers better, providing uniform heat distribution in smaller tanks with simpler maintenance. The selection hinges on fryer size, heating speed, and operational environment, with immersion heaters favored for heavy-duty commercial use and tubular heaters optimized for domestic applications.

Cost Analysis: Initial Investment and Long-term Value

Immersion heaters typically have a lower initial investment cost compared to tubular heaters, making them a budget-friendly option for deep fryer heating elements. However, tubular heaters offer greater durability and energy efficiency, leading to reduced maintenance expenses and operational costs over time. Choosing tubular heaters can result in better long-term value despite a higher upfront price, optimizing overall cost-effectiveness in deep fryer heating applications.

Immersion heater vs Tubular heater for deep fryer heating element Infographic

productvia.com

productvia.com