Blast freezers rapidly reduce the temperature of food, preserving texture, flavor, and nutritional value better than standard freezers, which cool at a slower pace. In commercial kitchens, blast freezers are ideal for preventing ice crystal formation and maintaining food quality during long-term storage. Standard freezers are more suitable for general storage needs but lack the fast freezing capabilities essential for high-volume, quality-sensitive food preparation.

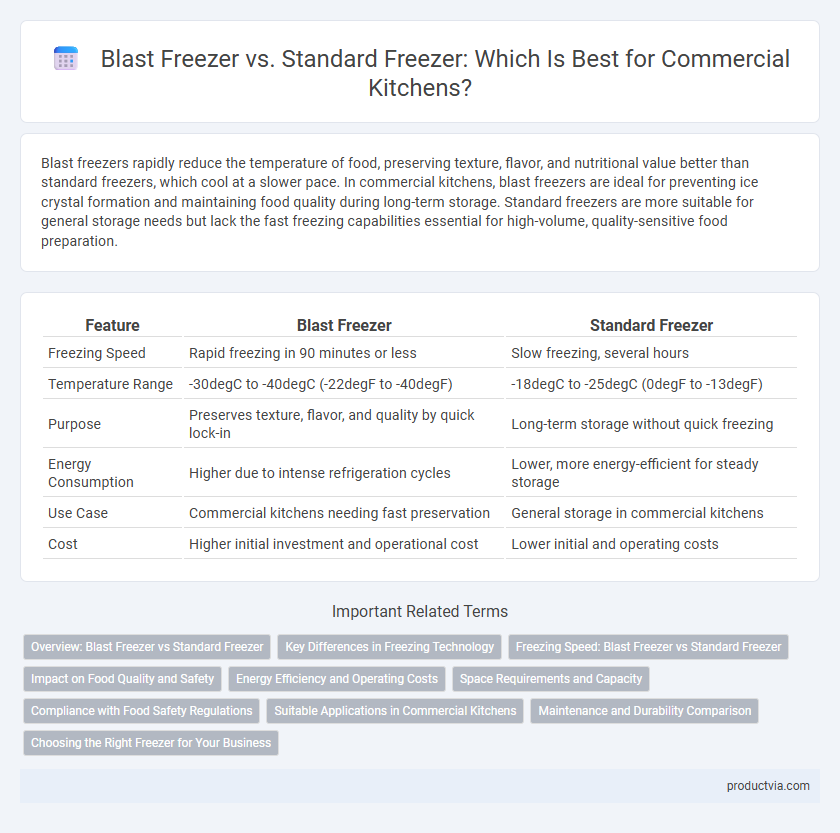

Table of Comparison

| Feature | Blast Freezer | Standard Freezer |

|---|---|---|

| Freezing Speed | Rapid freezing in 90 minutes or less | Slow freezing, several hours |

| Temperature Range | -30degC to -40degC (-22degF to -40degF) | -18degC to -25degC (0degF to -13degF) |

| Purpose | Preserves texture, flavor, and quality by quick lock-in | Long-term storage without quick freezing |

| Energy Consumption | Higher due to intense refrigeration cycles | Lower, more energy-efficient for steady storage |

| Use Case | Commercial kitchens needing fast preservation | General storage in commercial kitchens |

| Cost | Higher initial investment and operational cost | Lower initial and operating costs |

Overview: Blast Freezer vs Standard Freezer

Blast freezers rapidly reduce the temperature of food to -30degC to -40degC, preserving texture, flavor, and nutritional value by minimizing ice crystal formation. Standard freezers maintain food at around -18degC, suitable for longer-term storage but with slower freezing times that can degrade food quality. Commercial kitchens benefit from blast freezers for quick preservation and maintaining high food safety standards, while standard freezers are more economical for general storage needs.

Key Differences in Freezing Technology

Blast freezers use rapid air circulation at extremely low temperatures, typically around -30degF to -40degF, to freeze food quickly and preserve texture and nutritional value. Standard freezers operate at higher temperatures, generally between 0degF and -10degF, causing slower freezing that can lead to larger ice crystals and potential quality loss. The blast freezing process minimizes cellular damage, making it ideal for commercial kitchens requiring high-quality food preservation and reduced thawing time.

Freezing Speed: Blast Freezer vs Standard Freezer

Blast freezers rapidly reduce food temperature within minutes, significantly slowing bacterial growth and preserving texture and flavor, unlike standard freezers that cool at a slower rate over several hours. This accelerated freezing process in blast freezers prevents large ice crystals formation, ensuring higher food quality and minimizing moisture loss. Commercial kitchens benefit from blast freezers by improving food safety compliance and reducing thawing times during meal preparation.

Impact on Food Quality and Safety

Blast freezers rapidly lower the temperature of food items through intense cold air circulation, significantly reducing ice crystal formation and preserving texture and nutritional value compared to standard freezers. This rapid freezing process greatly minimizes bacterial growth, ensuring higher food safety standards essential for commercial kitchens. Standard freezers, while more economical, freeze food at slower rates, potentially compromising food quality and increasing the risk of microbial contamination.

Energy Efficiency and Operating Costs

Blast freezers utilize rapid freezing technology that significantly reduces ice crystal formation, preserving food quality while consuming more energy initially compared to standard freezers. Standard freezers operate at steady temperatures, offering lower upfront energy consumption but often result in higher long-term operating costs due to longer freezing times and increased food spoilage risk. Commercial kitchens benefit from blast freezers' efficiency in maintaining food freshness and reducing waste, which can offset higher energy use through lower overall operating expenses.

Space Requirements and Capacity

Blast freezers in commercial kitchens require less space due to their rapid cooling technology, enabling higher product turnover within compact units. Standard freezers often demand more square footage to accommodate larger storage volumes but involve slower freezing cycles. Choosing blast freezers maximizes capacity efficiency by minimizing ice crystal formation, preserving food quality while optimizing kitchen spatial layout.

Compliance with Food Safety Regulations

Blast freezers rapidly reduce food temperature to below 0degF, minimizing bacterial growth and ensuring compliance with stringent food safety regulations such as the FDA Food Code. Standard freezers cool food more slowly, increasing the risk of pathogen proliferation during the temperature transition period, which can lead to non-compliance in commercial kitchens. Using blast freezers helps maintain proper cold chain management and meets HACCP standards critical for food safety and quality control.

Suitable Applications in Commercial Kitchens

Blast freezers rapidly lower the temperature of foods, preserving texture, flavor, and nutritional value, making them ideal for commercial kitchens requiring quick cooling of fresh produce, seafood, and pre-cooked meals. Standard freezers maintain consistent low temperatures, suitable for long-term storage of frozen ingredients like meats, vegetables, and pre-packaged items. Commercial kitchens benefit from blast freezers for high-volume, time-sensitive operations, while standard freezers suit establishments with steady inventory turnover and less urgent cooling needs.

Maintenance and Durability Comparison

Blast freezers feature advanced compressor systems and robust insulation, reducing frost buildup and minimizing maintenance frequency compared to standard freezers in commercial kitchens. Their rapid freezing cycles help preserve equipment longevity by preventing ice crystal damage, while standard freezers often require more frequent defrosting and parts replacement. Durable components in blast freezers are engineered for high-demand environments, offering extended service intervals and lower long-term operational costs.

Choosing the Right Freezer for Your Business

Blast freezers rapidly lower food temperature to -20degF or lower, significantly preserving texture, flavor, and nutritional quality compared to standard freezers that typically maintain temperatures around 0degF. In commercial kitchens, blast freezers minimize ice crystal formation, reducing thawing time and preventing bacterial growth, which enhances food safety and quality. Choosing the right freezer depends on your volume of perishable goods, required freezing speed, and space availability, with blast freezers ideal for high-demand environments needing fast preservation.

Blast freezer vs standard freezer for commercial kitchens Infographic

productvia.com

productvia.com